info@loadcellsensor.com

info@loadcellsensor.com

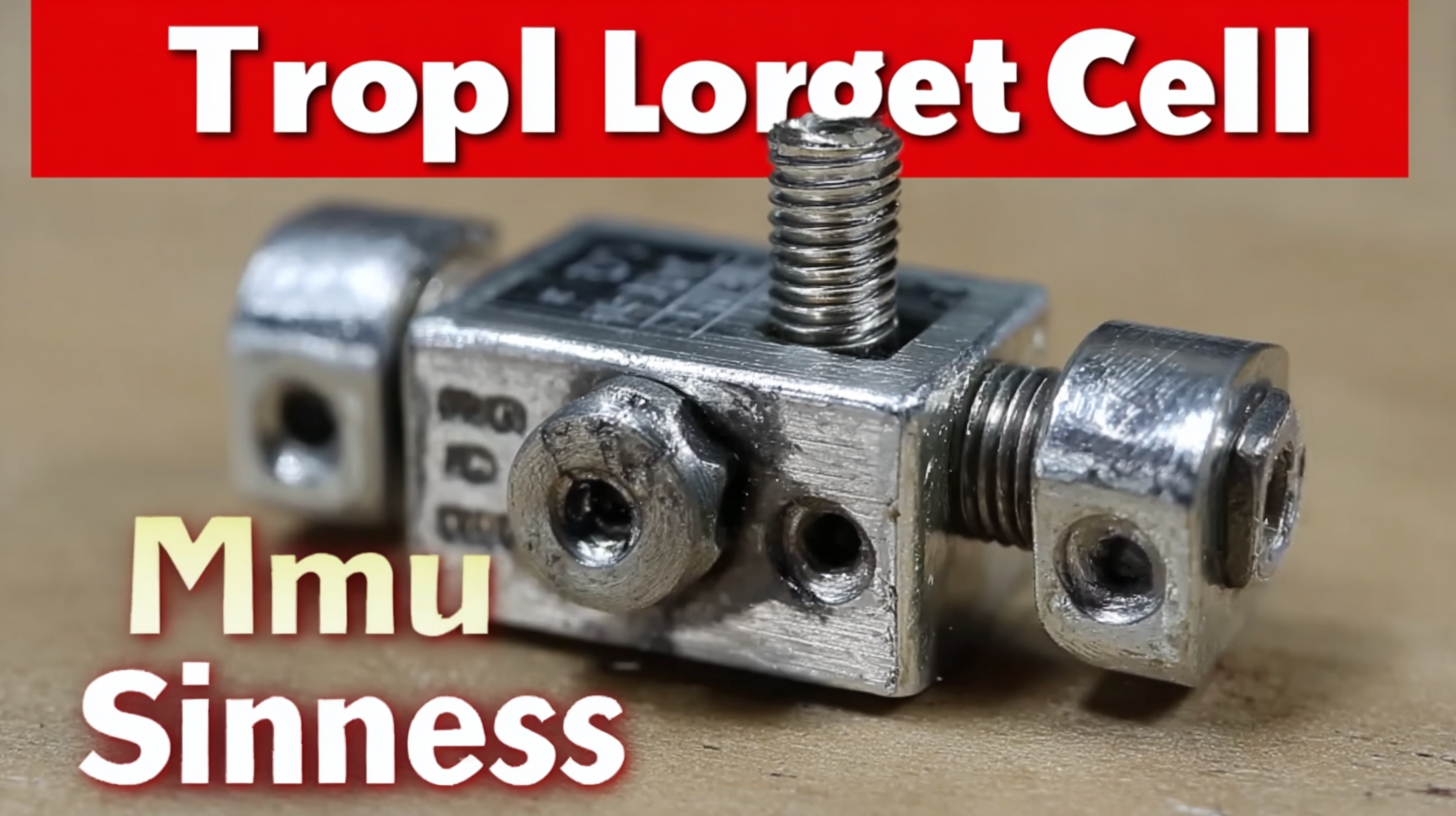

Common Issues Faced When Using Best Small Load Cells

In various industrial applications, the importance of accurate weight measurement cannot be overstated, particularly when it comes to the utilization of Small Load Cells. According to a report by MarketsandMarkets, the load cell market is projected to reach $1.85 billion by 2024, indicating a growing reliance on this technology across sectors such as manufacturing, automotive, and healthcare.

Despite their widespread use, users often encounter common issues that can hinder performance and measurement accuracy. From environmental factors like temperature fluctuations to installation challenges and calibration errors, understanding these pitfalls is crucial for optimizing the functionality of Small Load Cells. This tutorial aims to explore these common problems and provide practical solutions to enhance the efficiency and reliability of your load measurement systems.

Understanding Load Cell Basics and Their Importance

Load cells play a vital role in various industries, enabling accurate measurement of force and weight. Understanding the basics of load cells is crucial for businesses, especially considering that the global load cell market was valued at approximately $1.12 billion in 2020 and is projected to reach $1.62 billion by 2026, according to a report by Mordor Intelligence. This growth signifies the importance of reliable load cells in manufacturing, logistics, and scientific research. Properly functioning load cells ensure that data collected is precise, which minimizes errors in production and enhances overall efficiency.

When working with small load cells, users may encounter several common issues, such as calibration errors, environmental interference, and mechanical loading challenges. Calibration is essential; a report by the National Institute of Standards and Technology highlights that inaccurate calibration can lead to measurement deviations of over 5%. Ensuring that load cells are adjusted correctly can significantly impact the reliability of measured data.

Tip: Always perform routine calibrations to maintain accuracy.

Moreover, environmental factors like temperature fluctuations and electromagnetic interference can adversely affect load cell performance. According to a study by the International Society for Measurement and Control, exposure to extensive temperature variations can lead to shifts in readings by up to 0.1% per degree Celsius.

Tip: Implement environmental controls and shielding methods to mitigate these effects.

Common Challenges in Accurate Weight Measurements

When using small load cells for accurate weight measurements, several common challenges arise that can impact the precision of results. One significant issue is the calibration of the load cell. According to industry reports, inaccuracies in calibration can lead to discrepancies as high as 5%, which can severely skew measurements, especially in delicate applications such as pharmaceuticals or high-precision manufacturing.

Another challenge is the environmental factors that affect load cells during operation. Variations in temperature and humidity can alter the cell's performance, leading to inconsistent readings. A 2022 study highlighted that environmental conditions could account for up to 10% variation in weight measurements if not properly controlled. This is particularly crucial in applications such as shipping and logistics, where precise weight data is essential for compliance and cost management.

Furthermore, the design and construction of load cells can also introduce errors. A survey of load cell manufacturers revealed that nearly 30% experienced issues due to mechanical design flaws, such as sensitivity to lateral loads or improper mounting. These factors not only affect measurement accuracy but can also lead to premature wear and tear, increasing replacement costs and downtime in critical processes. Addressing these challenges is essential for maintaining high standards in weighing accuracy across various industries.

Technical Malfunctions: Identifying and Troubleshooting

When working with small load cells, users often encounter technical malfunctions that can impede accurate measurements and affect overall performance. Common issues include signal drift, where the output fluctuates despite a stable loading condition. This problem can arise due to environmental factors such as temperature changes or electromagnetic interference. To troubleshoot this issue, first, ensure the load cell is properly calibrated. An inappropriate calibration can exacerbate drift problems. Additionally, using a well-shielded cable can help reduce interference from external sources.

Another frequent challenge involves electrical connection faults, which can lead to erratic readings or complete failure of the load cell. Inspecting the wiring and connectors for any visible signs of damage or corrosion is essential. Furthermore, improper mounting of load cells can result in misalignment and stress concentration, affecting their accuracy. It's critical to follow the manufacturer's guidelines for installation to ensure proper loading conditions. Regular maintenance checks and prompt identification of issues can significantly enhance the reliability and longevity of small load cells, making troubleshooting an indispensable skill for users.

Common Issues Faced When Using Best Small Load Cells

Environmental Factors Affecting Load Cell Performance

When using small load cells, understanding the environmental factors that can impact their performance is crucial. One of the primary issues faced is temperature fluctuations. Load cells are sensitive to changes in temperature, which can lead to variations in readings. If a load cell operates in extreme heat or cold, it may expand or contract, affecting its ability to accurately measure weight. Maintaining a consistent temperature is essential for ensuring reliability and precision in measurements.

Another vital factor is humidity. Excess moisture in the air can cause corrosion in load cell components, leading to malfunction or decreased accuracy over time. Likewise, exposure to dust and contaminants can also hinder performance, as dirt accumulation on sensing elements may interfere with readings. Therefore, implementing protective enclosures or choosing load cells specifically designed for harsh environments can significantly mitigate these risks, ensuring optimal functionality in various conditions. Proper installation and regular maintenance checks can further enhance the longevity and accuracy of small load cells, addressing common environmental challenges effectively.

Best Practices for Maintenance and Calibration of Load Cells

Calibration and maintenance are critical components in ensuring the accurate operation of small load cells. According to a report by the International Society of Automation, regular calibration can enhance measurement accuracy by up to 5%, significantly reducing the risk of errors that could lead to costly operational mistakes. Ensuring that load cells are calibrated according to the manufacturer's guidelines is vital; this typically involves using certified masses and following proper procedures to eliminate any potential biases that can affect results.

Moreover, regular maintenance includes visual inspections and functionality tests as outlined in the IEEE Standards for Load Cells. These practices not only help in extending the lifespan of the equipment but also safeguard against common issues such as drift and non-linearity. A study by the National Institute of Standards and Technology (NIST) indicates that neglecting routine checks can lead to performance degradation, potentially resulting in measurement errors upwards of 10%. By adhering to best practices for both calibration and maintenance, operators can ensure consistent performance and reliability in their load measurement systems.

Common Issues Faced When Using Best Small Load Cells - Best Practices for Maintenance and Calibration of Load Cells

| Issue | Symptoms | Best Practice for Maintenance | Calibration Frequency |

|---|---|---|---|

| Drift | Inconsistent readings over time | Regular zeroing and recalibration | Every 6 months |

| Non-linearity | Errors in measurements across different load levels | Perform range checks and adjust settings | Every year |

| Mechanical damage | Physical damage observed on load cell | Regular visual inspections and protective measures | Monthly |

| Environmental factors | Unexpected fluctuations due to temperature or humidity | Keep load cells in controlled environments | Every 3 months |

| Electrical noise | Erratic readings due to interference | Use shielded cables and proper grounding | As needed |