sales@loadcellsensor.com

sales@loadcellsensor.com

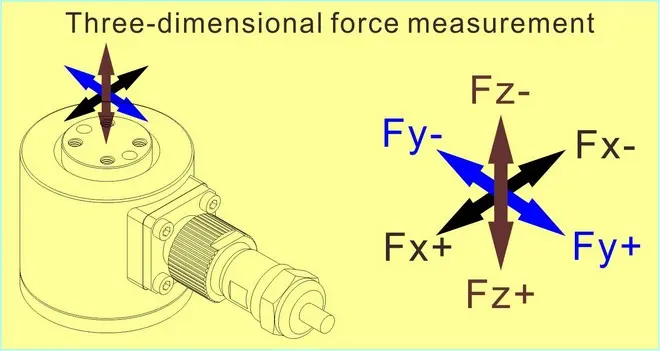

3D Load Cell 5kg 10kg 20kg 50kg Multi-axis Sensor

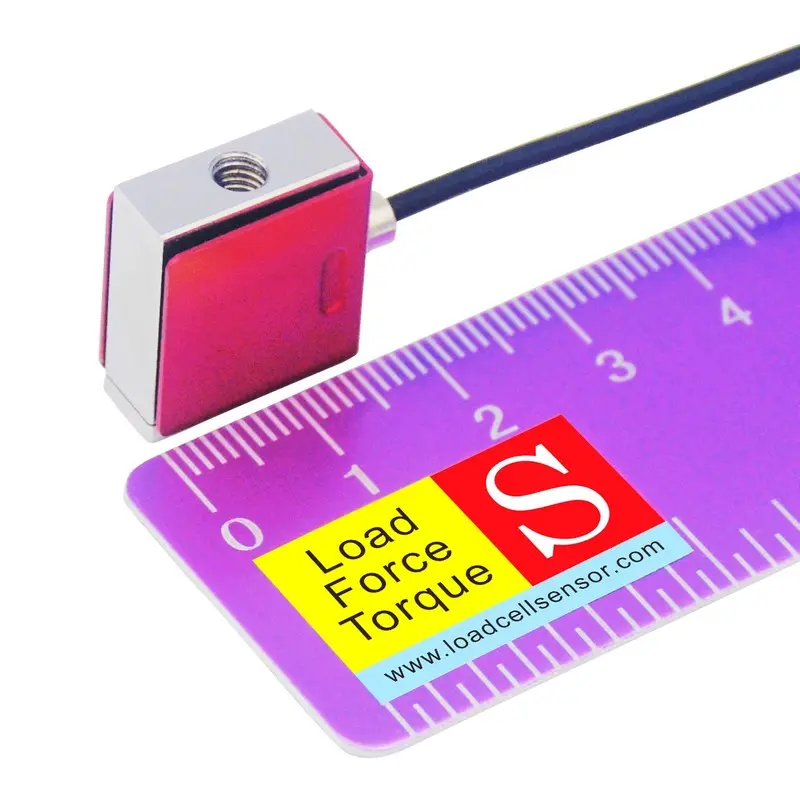

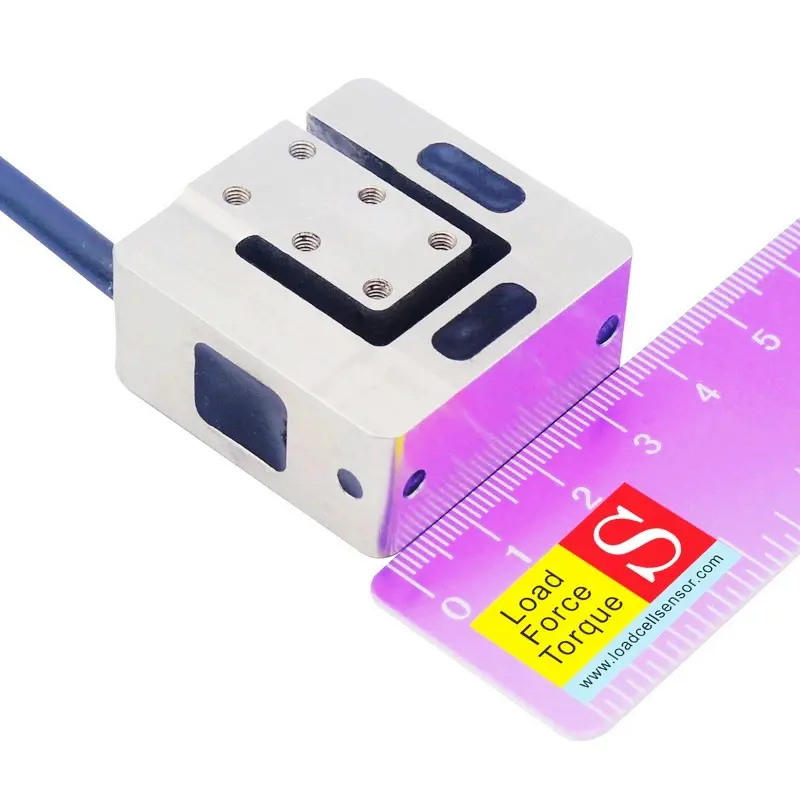

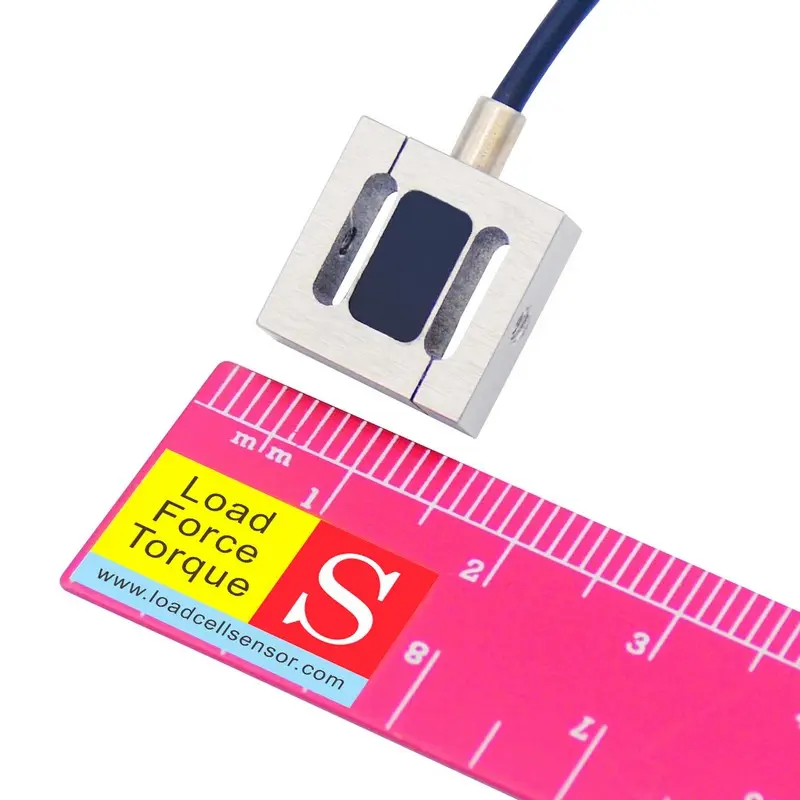

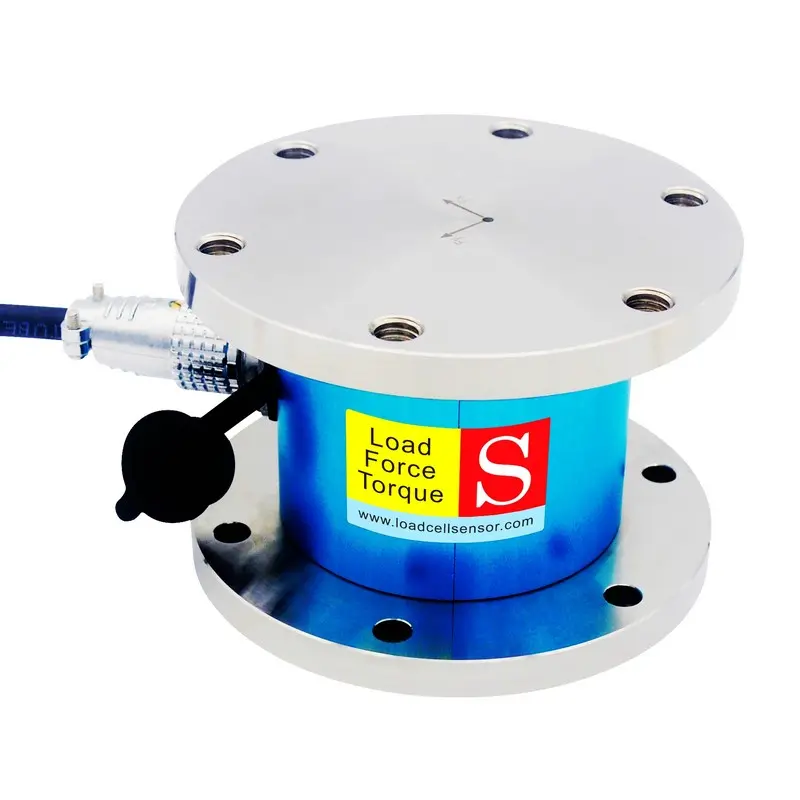

The LCM06 3D Load Cell is a compact and high-precision sensor specifically designed for multi-dimensional force measurement. Constructed from robust stainless steel, it features a flange-to-flange design that ensures secure, stable, and straightforward mounting. This structural innovation not only enhances mechanical integration but also maintains alignment accuracy, making it ideal for critical measurement applications where precision and reliability are paramount.

Available in rated capacities of 5kg, 10kg, 20kg, and 50kg, the LCM06 triaxial load cell is engineered to measure forces in both tension and compression, offering flexibility in environments with dynamic or bidirectional loading. Its strength lies in its ability to capture simultaneous force readings along three orthogonal axes (Fx, Fy, Fz) without requiring vector calculations or signal conversion, delivering real-time, direct output for ease of interpretation and system integration.

Each axis within the LCM06 multi-axis sensor is equipped with an independent strain gauge bridge, providing a clean and accurate electrical output that represents the applied force. For added compatibility, this load cell can be paired with analog signal amplifiers offering -5-5V, 0-10V, or 4~20mA outputs, as well as digital amplifiers supporting RS485 or RS232 communications. These options ensure the LCM06 can be effortlessly integrated into PLCs, DAQs, and industrial control systems, making it suitable for both development and production environments.

Typical Applications of the LCM06 3-Axis Load Cell

- Robotics and Automation

In robotic systems, particularly those involving end-effector control or force-feedback applications, the LCM06 multi-axis load cell plays a vital role. By delivering real-time data on applied forces in three dimensions, it allows robots to interact with objects more safely and precisely. This is essential in collaborative robotics (cobots), assembly automation, and delicate material handling tasks.

- Aerospace Testing and Development

The aerospace sector demands rigorous validation of materials, components, and structural systems under complex load conditions. The LCM06 is used in load testing of aircraft parts, vibration analysis, and wind tunnel experimentation, offering precise feedback on stress distribution across all axes. Its compact profile also allows it to fit in tight testing setups where space is limited.

- Automotive Component Evaluation

In automotive R&D, the LCM06 3-axis sensor is instrumental in analyzing force dynamics on levers, pedals, and structural components. For instance, it can measure the three-dimensional force profile during gear shifting or brake pedal actuation, helping engineers refine ergonomics and performance. The LCM06 supports performance tuning and failure analysis under real-world load simulations.

- Medical Device Innovation

In the medical field, the LCM06 supports development and calibration of diagnostic tools, rehabilitation devices, and surgical robots. Its sensitivity and multi-axis capability allow for precise force monitoring in patient-interactive systems, ensuring safety and functionality. Applications include prosthetic testing, pressure distribution analysis, and haptic device feedback.

- Operating Lever Force Feedback

The LCM06 is well-suited for assessing operating lever mechanics in industrial and vehicle control systems. It enables accurate monitoring of operator input, ensuring that levers, joysticks, or control arms provide the intended mechanical response. This is particularly valuable for ergonomic design validation and feedback optimization.

In conclusion, the LCM06 3-axis force sensor delivers a perfect combination of precision, strength, and integration ease. Its compact footprint, flange-based design, and multi-output support make it adaptable across diverse industries. For specialized needs, custom versions of the LCM06 are available, allowing for tailored solutions that meet the most challenging force measurement scenarios with confidence.