sales@loadcellsensor.com

sales@loadcellsensor.com

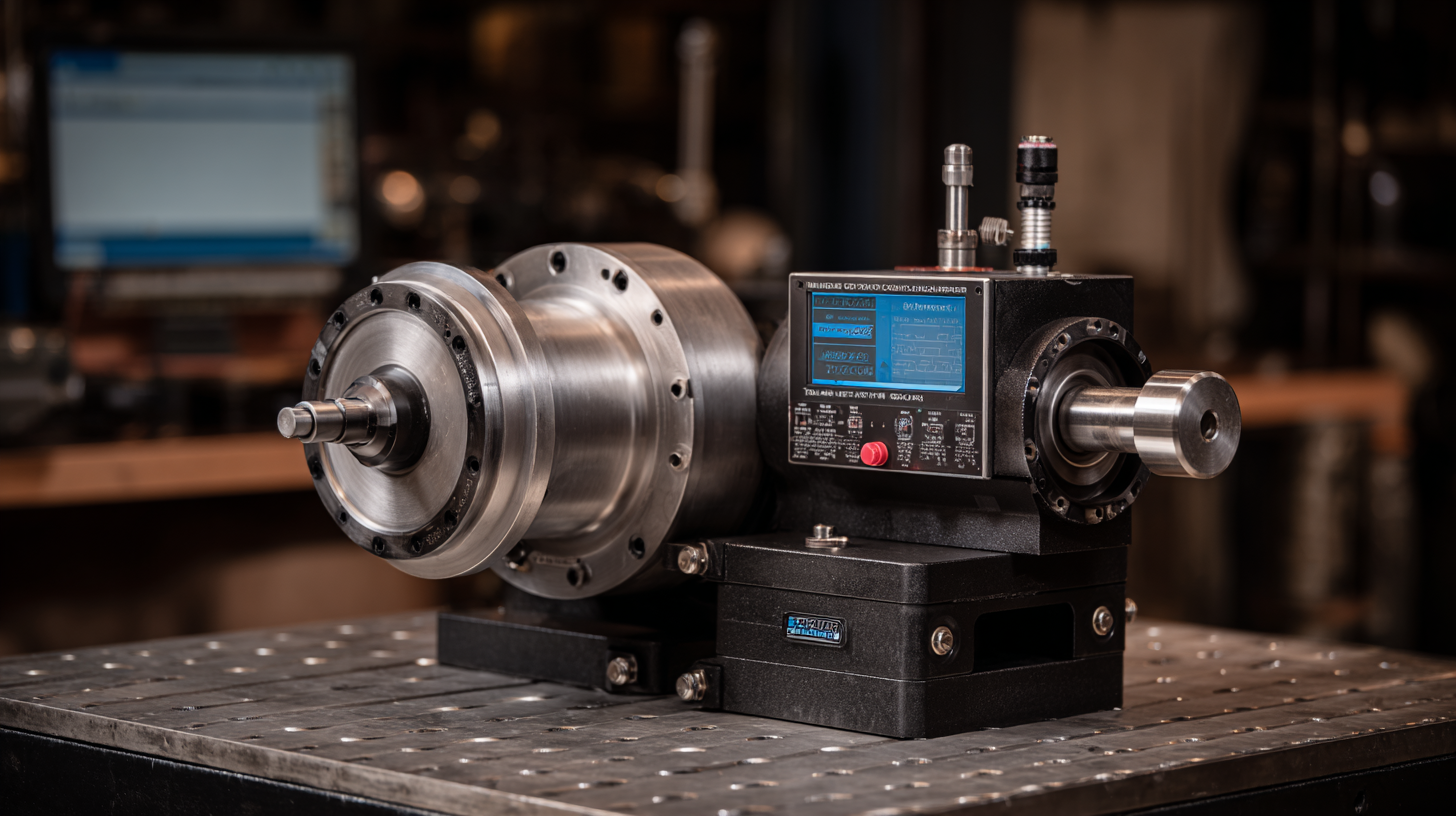

Revolutionizing Measurements An Insight into the 2025 Trends for Best Rotary Torque Transducers

In the rapidly evolving landscape of industrial measurements, Rotary Torque Transducers are set to play a pivotal role in enhancing precision and efficiency across various applications. As industries strive for greater accuracy and performance, recent market analyses indicate that the demand for these devices is projected to surge by over 15% annually through 2025. This growth is attributed to the increasing need for advanced torque measurement solutions in sectors such as automotive, aerospace, and energy. Furthermore, the integration of innovative technologies, including IoT capabilities and advanced data analytics, is transforming how torque measurements are captured and interpreted. As we delve into the key trends anticipated for 2025, it becomes clear that understanding the benefits and applications of Rotary Torque Transducers will be essential for companies aiming to maintain a competitive edge in their respective fields.

Emerging Technologies Transforming Rotary Torque Transducer Designs in 2025

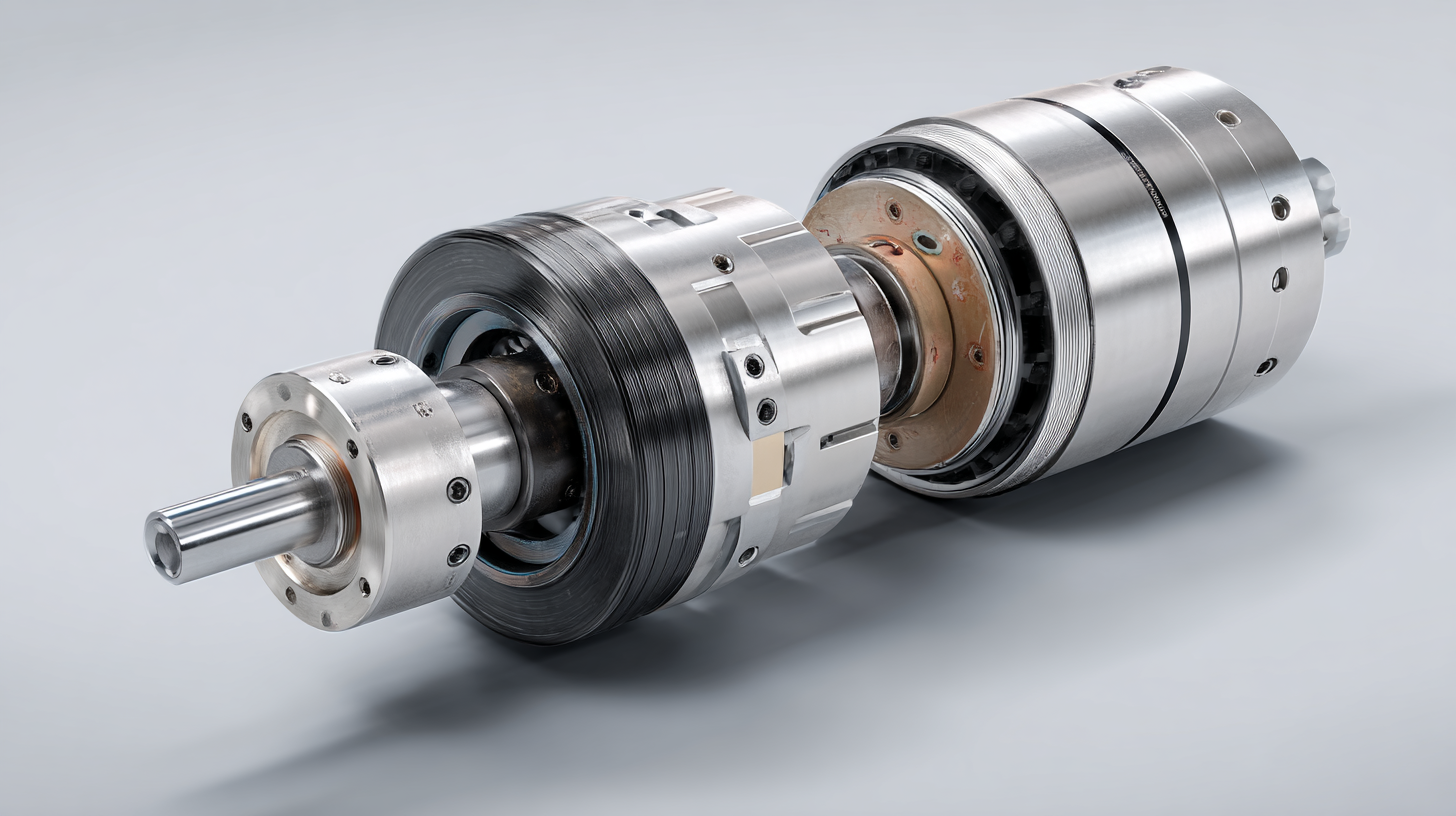

The landscape of rotary torque transducer designs is set to undergo significant transformation in 2025, driven by emerging technologies that enhance their efficiency and precision. One of the most notable trends is the integration of advanced materials and miniaturization techniques. Innovative composite materials are being utilized to create lighter and more durable transducers, allowing for higher sensitivity and better performance under extreme conditions. This shift not only improves accuracy but also extends the lifespan of the devices, making them more reliable across various applications.

The landscape of rotary torque transducer designs is set to undergo significant transformation in 2025, driven by emerging technologies that enhance their efficiency and precision. One of the most notable trends is the integration of advanced materials and miniaturization techniques. Innovative composite materials are being utilized to create lighter and more durable transducers, allowing for higher sensitivity and better performance under extreme conditions. This shift not only improves accuracy but also extends the lifespan of the devices, making them more reliable across various applications.

Additionally, the incorporation of smart technology is revolutionizing rotary torque transducers. With the advent of IoT (Internet of Things) capabilities, these devices can now provide real-time data analytics, enabling users to monitor performance remotely and make informed decisions quickly. This connectivity not only increases operational efficiency but also enhances predictive maintenance, reducing downtime in critical applications. As we move into 2025, the convergence of these technologies will undoubtedly redefine the standards for precision measurement and set the stage for smarter industrial processes.

Key Factors Driving the Demand for High-Precision Torque Measurements

The demand for high-precision torque measurements is surging, driven by advancements in various industries such as automotive, aerospace, and manufacturing. According to a recent report by MarketsandMarkets, the global torque sensor market is expected to grow from USD 556 million in 2023 to USD 887 million by 2025, at a compound annual growth rate (CAGR) of 24.1%. This growth signals a clear need for more precise and reliable torque measurement solutions, particularly as industries increasingly focus on quality control and product performance.

Key factors influencing this demand include the rise of automation and the integration of Industry 4.0 technologies, which require enhanced measurement capabilities to ensure operational efficiency. Additionally, stringent regulations in safety and quality standards are pushing manufacturers to adopt high-precision torque transducers. As reported by Allied Market Research, the automotive sector alone accounted for over 30% of the torque sensor market in 2022, emphasizing the critical role of accurate torque measurements in enhancing vehicle performance and safety. The transition towards electric vehicles further underscores this necessity, as torque measurements are vital in optimizing battery performance and efficiency.

Innovations in Data Processing and Connectivity for Torque Transducers

As we approach 2025, the field of rotary torque transducers is undergoing significant transformations, particularly in data processing and connectivity. Recent industry reports indicate that the global torque transducer market is projected to grow at a CAGR of 6.7%, reaching approximately $1.5 billion by 2025. This growth is largely driven by advancements in digital technology that enhance the accuracy and reliability of measurements. Innovations such as IoT integration and wireless data transmission are at the forefront, allowing for real-time monitoring and analytics, which are crucial in various applications, including automotive and aerospace industries.

To maximize the benefits of these advancements, consider the following tips:

First, invest in torque transducers with robust connectivity options, such as Wi-Fi or Bluetooth, to streamline your data collection process. This not only improves efficiency but also facilitates easier integration with existing systems.

Second, prioritize devices that offer advanced data processing capabilities. These can filter noise and provide high-resolution measurements, ensuring that your data is actionable and accurate. By focusing on these innovations, users can significantly enhance performance and decision-making in their operations.

Market Trends Shaping the Future of Rotary Torque Sensors in Various Industries

The landscape of rotary torque sensors is evolving rapidly, with various industries setting the stage for transformative trends by 2025. As demand for precision measurements increases, companies are investing in advanced technologies to enhance the accuracy and reliability of torque transducers. Innovations, such as IoT integration and wireless communication, are driving the deployment of smarter devices that offer real-time data collection and analysis, improving operational efficiency across the board.

Tip: When selecting a rotary torque sensor, consider compatibility with existing systems. This ensures seamless integration and maximizes the benefits of advanced analytics offered by new technologies.

Moreover, industries such as automotive, aerospace, and manufacturing are increasingly prioritizing sustainability, prompting manufacturers to focus on creating eco-friendly torque sensors. The push for greener practices is not only about reducing emissions but also about improving energy efficiency in operations. Thus, businesses are likely to see a shift towards sensors that utilize materials and processes that align with environmental goals.

Tip: Stay informed about regulatory standards related to sustainability in your industry, as compliance may influence your choice of torque transducers in the near future.

Best Practices for Selecting the Right Rotary Torque Transducer for Your Application

When it comes to selecting the right rotary torque transducer for your application, understanding the specific requirements of your project is crucial. Begin by assessing the torque range and accuracy needed for your measurements. Various applications, such as automotive testing or industrial manufacturing, may demand different specifications. Ensure that you choose a transducer that not only accommodates your torque requirements but also offers the precision necessary for accurate data collection.

In addition to understanding torque levels, consider the environmental factors that may influence the performance of the transducer. Factors like temperature fluctuations, exposure to moisture, or potential vibrations can significantly affect the readings. Opt for transducers that come with robust housing and are designed to operate under challenging conditions. Lastly, don’t overlook the importance of compatibility with your existing systems. Ensure that the chosen transducer can easily integrate with your data acquisition systems and is supported by reliable software for real-time analysis. By carefully evaluating these aspects, you can make an informed choice that maximizes performance and reliability in your applications.