sales@loadcellsensor.com

sales@loadcellsensor.com

Understanding the Basics of Torque Sensor Functionality and Applications

Torque sensors play a crucial role in various industries by providing essential data that enhances efficiency and safety in mechanical systems. According to a recent market research report published by MarketsandMarkets, the global torque sensor market is projected to reach USD 1.38 billion by 2025, growing at a CAGR of 5.7% from 2020. This growth is driven by the increasing demand for accurate measurement in manufacturing processes, automotive applications, and robotics. The functionality of torque sensors encompasses a wide range of applications, from monitoring engine performance to providing feedback in automation systems. As industries continue to adopt advanced technologies for precision and reliability, understanding the basics of torque sensor functionality becomes imperative for engineers and decision-makers alike. This blog will explore key strategies for effectively integrating torque sensors into operational practices, ensuring improved performance and operational excellence.

What is a Torque Sensor and How Does It Work?

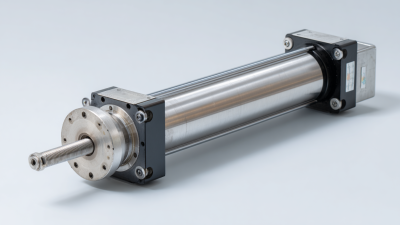

Torque sensors are crucial instruments used to measure the torque generated by a rotating object, providing valuable data for various applications, particularly in automotive and industrial settings. These sensors operate based on principles of mechanical engineering, utilizing strain gauges or other sensing technologies to detect the torsional force exerted on components such as driveshafts, motors, and gear systems. The output data from torque sensors enables engineers to monitor performance, ensure the safety of mechanical systems, and optimize efficiency across different applications.

In recent advancements, the integration of torque sensors with electric motors has revolutionized vehicle performance, especially in scenarios involving steep inclines and variable terrains. For instance, in the context of CVT (Continuously Variable Transmission) systems, the ability to precisely measure the torque allows for improved power delivery and better handling of challenging driving conditions. This integration not only enhances the durability of the transmission but also ensures that the motor operates efficiently within its optimal torque range, turning potential power losses into enhanced vehicle dynamics—especially under demanding conditions such as climbing steep hills.

Key Components of Torque Sensors Explained

Torque sensors are vital components in various applications, particularly in automotive and robotics sectors, where precision and safety are paramount. The essential parts of a torque sensor include the sensing element, which directly measures the torque, and the signal processing unit that interprets and communicates these measurements. Advanced technologies such as capacitive steering sensors are increasingly utilized in modern vehicles to enhance driver assistance systems (ADAS). According to industry reports, the integration of torque sensors within ADAS is projected to improve vehicle safety significantly by reducing human error, thus paving the way for semi-automated driving.

Another foreground application of torque sensors is in robotics, where they play a crucial role in enabling precise motion control. A recent analysis indicated that the market for sensors used in robotics is expected to grow substantially, driven by innovations in mobile robotics and drones. These sensors not only enhance operational efficiency but also improve the responsiveness of robotic arms, which rely heavily on detailed torque feedback to perform tasks accurately. The advancements in sensor technology, including the optimization of piezoelectric layouts and elastic structures, demonstrate a clear trajectory towards increasing sensitivity and reliability in torque measurement.

Common Applications of Torque Sensors in Various Industries

Torque sensors play a critical role in various industries by providing real-time measurements of torque, crucial for ensuring the safety and efficiency of machinery. One common application of torque sensors is in the automotive sector, where they are employed to test engine components, such as crankshafts and gearboxes. By accurately measuring the torque output, manufacturers can optimize performance and enhance reliability, leading to improved vehicle efficiency.

Torque sensors play a critical role in various industries by providing real-time measurements of torque, crucial for ensuring the safety and efficiency of machinery. One common application of torque sensors is in the automotive sector, where they are employed to test engine components, such as crankshafts and gearboxes. By accurately measuring the torque output, manufacturers can optimize performance and enhance reliability, leading to improved vehicle efficiency.

Another significant application can be found in the manufacturing industry, particularly in assembly lines. Torque sensors help ensure that bolts and fasteners are tightened to the correct specifications, preventing potential failures in structures or machinery. This is particularly important in the aerospace sector, where precision and safety are paramount. Additionally, torque sensors are increasingly being utilized in robotics and automation, enabling smarter operations through feedback control mechanisms that adjust torque based on real-time data, thus enhancing the overall performance of automated systems.

Tips for Choosing the Right Torque Sensor for Your Needs

When selecting the right torque sensor for your specific applications, it’s essential to consider several key factors that can significantly impact performance and accuracy. First and foremost, the measurement range of the torque sensor should align with the expected values you will be working with. If your application requires measuring high torque values, ensure that the sensor can handle these levels without compromising its integrity or accuracy. Additionally, understanding the sensor's resolution and accuracy specifications will help you assess if it meets your requirements for precision in measurements.

Another critical aspect is the type of sensor technology used, such as strain gauge, optical, or magnetic. Each type comes with its unique advantages and drawbacks, making it vital to match the technology with your operational needs. For example, strain gauge sensors are commonly chosen for their high accuracy and adaptability while being suitable for various applications. Besides, consider the environmental conditions in which the sensor will operate—temperature fluctuations, humidity, and potential exposure to chemicals can influence sensor performance and longevity. By thoroughly evaluating these factors, you can ensure that the torque sensor you choose perfectly fits your operational needs, leading to better efficiency and reliability in your applications.

Future Trends in Torque Sensor Technology and Innovations

Recent advancements in torque sensor technology are poised to significantly transform various industries, particularly automotive and manufacturing. According to a report by Industry Research, the global torque sensor market is projected to grow at a CAGR of 9.1% from 2021 to 2026, reaching approximately $850 million by 2026. This growth is primarily driven by the increasing demand for precision measurement and control in production processes, alongside the rising adoption of electric vehicles which require advanced sensing technologies for optimal performance.

Innovations such as wireless torque sensors and IoT integration are at the forefront of these trends. Wireless sensors eliminate the constraints of traditional wiring, allowing for more flexible installations and real-time data monitoring. A recent study from MarketsandMarkets highlights that the IoT-enabled torque sensors market will expand rapidly, with an expected increase of over 15% annually through 2025. This integration not only enhances operational efficiency but also facilitates predictive maintenance, reducing downtime and operational costs across sectors. As industries continue to embrace these technologies, torque sensors will undoubtedly play a crucial role in enhancing precision, safety, and efficiency in their respective applications.

Related Posts

-

Exploring Innovative Torque Sensor Types: Real-World Applications and Benefits

-

Maximizing Precision: Key Techniques for Effective Torque Sensor Implementation

-

Unleashing China's Manufacturing Excellence: A Deep Dive into the Best Torque Sensor Innovations

-

Precision Engineering: Chinese Manufacturing Innovating Global Torque Transducer Solutions

-

Navigating the Global Standards for Best Torque Sensor Imports and Exports

-

5 Compelling Reasons Why Torque Sensors Revolutionize Industrial Applications