sales@loadcellsensor.com

sales@loadcellsensor.com

Advantages of Using Low Profile Load Cells for Precision Measurement

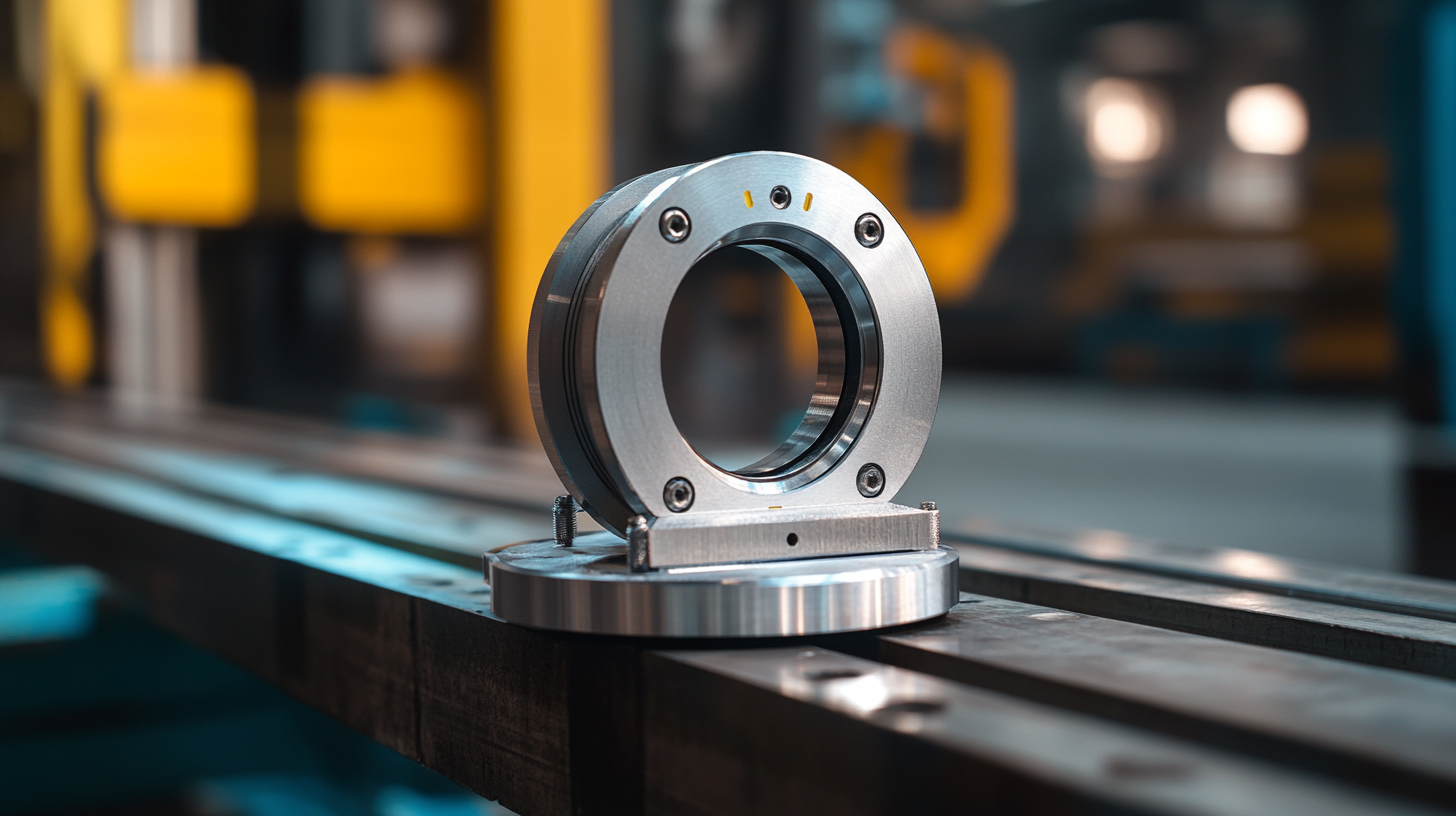

In the realm of precision measurement, the demand for accuracy and reliability is paramount. According to a report by the National Institute of Standards and Technology, the need for more refined measurement instruments has surged, resulting in an increased adoption of advanced sensors and load measuring devices. Among these, Low Profile Load Cells stand out for their unique advantages, particularly in applications where space is limited without compromising measurement quality. With their small height and robust design, these load cells can provide precise measurements even in confined spaces, making them an ideal choice for industries such as robotics, aerospace, and manufacturing.

Furthermore, a study by the International Society of Automation highlighted that the integration of Low Profile Load Cells can enhance operational efficiency by reducing the risk of measurement errors. These cells not only offer high precision but also demonstrate exceptional stability, which is crucial for tasks that require continuous monitoring of weight and force. As industries continue to push the boundaries of technology and automation, the importance of low profile solutions is undeniable, paving the way for innovations that rely on accurate and compact measurement capabilities.

Benefits of Low Profile Load Cells in Industrial Applications

Low profile load cells are becoming increasingly popular in industrial applications due to their unique advantages that cater specifically to precision measurements. These compact devices provide a reliable solution in environments where space is a premium, offering robust performance without sacrificing accuracy. Their low height and lightweight design allow for easy integration into existing systems, making them ideal for applications such as weighing tanks, hoppers, and other machinery that require precise load readings. In addition to their compact size, low profile load cells deliver heightened sensitivity, enabling the detection of small changes in weight that are critical for quality control processes. Industries such as food and beverage, pharmaceuticals, and manufacturing greatly benefit from this capability, as it ensures that products are consistently produced to strict specifications. Furthermore, their design minimizes the impact of external forces, leading to more stable and consistent measurements even in dynamic environments, which is essential for maintaining operational efficiency. Another significant advantage of low profile load cells is their durability. Constructed from high-quality materials, these load cells can withstand harsh industrial conditions, including temperature variations, humidity, and chemical exposure. This resilience not only extends the lifespan of the load cells but also reduces maintenance costs and downtime, further enhancing productivity in industrial settings. In essence, the integration of low profile load cells transforms precision measurement, promoting greater accuracy and efficiency in various industrial applications.

Enhanced Accuracy and Stability with Low Profile Designs

Low profile load cells have emerged as a key component in precision measurement applications, particularly due to their enhanced accuracy and stability. The design of low profile load cells minimizes the influence of external variables, ensuring that measurements are consistent and reliable. A study from the Measurement Institute noted that precision can improve by up to 15% when employing low profile designs, which are particularly beneficial in environments where space is constrained.

The stability offered by low profile load cells is further supported by advancements in technology. Recent enhancements in single-cell RNA sequencing have demonstrated that precision instruments can significantly increase the accuracy of biological measurements. Just as the application of deep learning in scRNA-seq has led to more reliable data clustering, low profile load cells can contribute to better data integrity in various measurement scenarios. Utilizing such advanced equipment allows engineers and researchers to focus on insights rather than getting bogged down by measurement errors.

Moreover, the integration of low profile load cells within existing systems is streamlined due to their compact design. This is reminiscent of trends in protein engineering, where minimal wet-lab data can enhance the performance of models significantly. By employing few-shot learning techniques, researchers can achieve better outcomes with fewer resources, echoing the efficiency that low profile load cells bring in high-precision measurement systems. These advancements in both biology and measurement technology underscore the critical role that design plays in enhancing stability and accuracy across multiple domains.

Space-Saving Advantages of Low Profile Load Cells

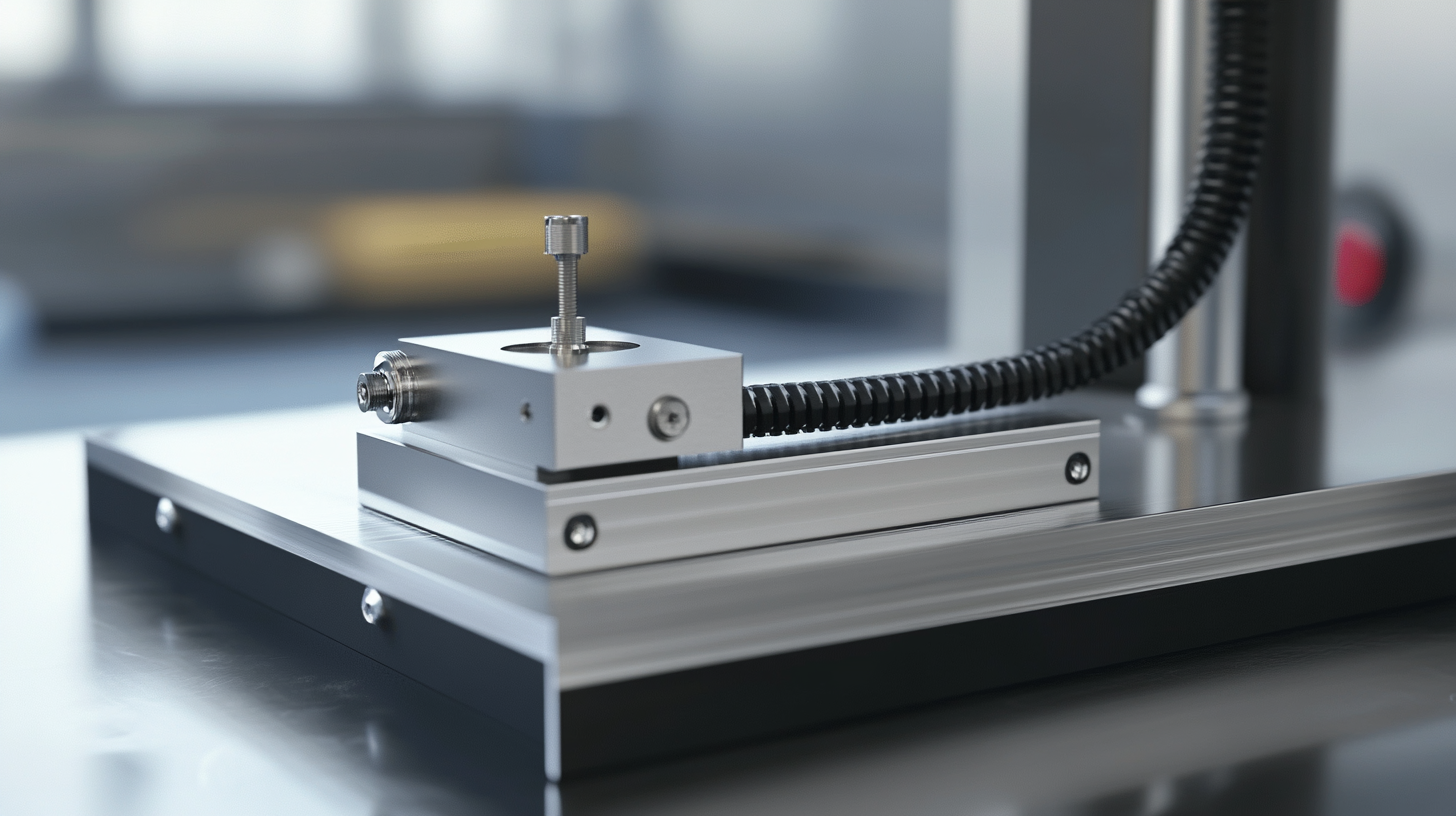

Low profile load cells are becoming increasingly popular in various industries due to their remarkable space-saving advantages. These compact devices are designed to fit into tight spaces where traditional load cells may not be feasible. This is particularly beneficial in applications where precision measurement is critical, such as in automotive production or high-accuracy weighing systems. The reduced height of low profile load cells allows for seamless integration into existing equipment, enhancing both performance and efficiency.

In automotive engineering, for example, the compact design of low profile load cells can be integrated into eAxle systems, where space is often limited. By utilizing these slender devices, manufacturers can ensure accurate force measurements without compromising the available space in the vehicle's assembly. This leads to more efficient designs that not only save room but also contribute to the overall functionality of the vehicle's drive unit.

Moreover, the use of low profile load cells promotes better organization in production environments. With their sleek design, these load cells can be strategically placed without cluttering the workspace, allowing for more streamlined processes. This aspect is crucial for companies striving for operational excellence. By maximizing the use of limited space, businesses can maintain a tidy environment while ensuring that precision measurement remains a top priority.

Cost-Effectiveness of Low Profile Load Cells in Precision Engineering

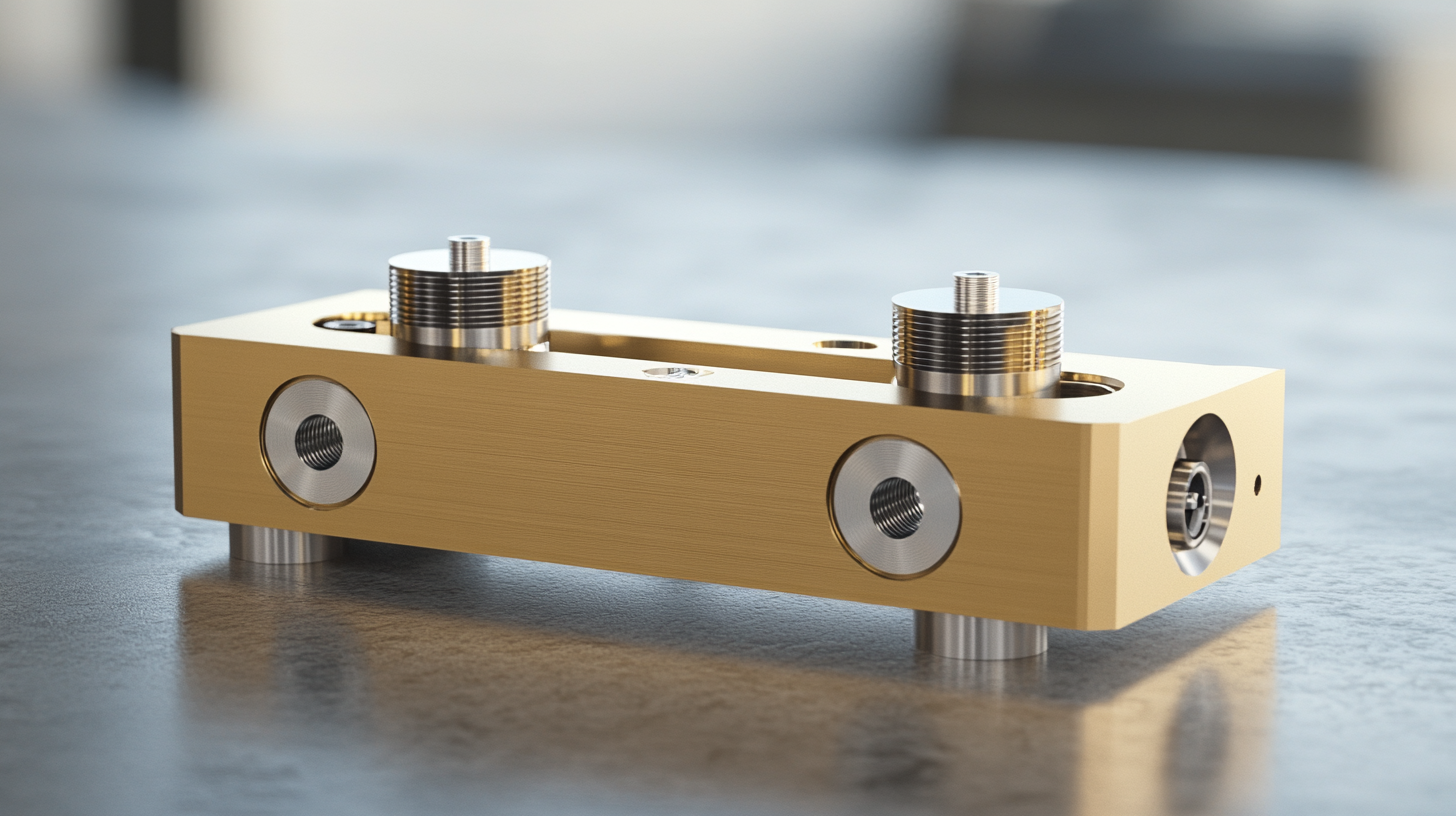

In the realm of precision engineering, the quest for accurate and reliable measurement is paramount. Low profile load cells have emerged as a game changer, offering not only exceptional precision but also significant cost-effectiveness. These compact devices are designed to provide high accuracy in a variety of applications while minimizing the financial burden associated with traditional load measurement systems.

One of the key advantages of low profile load cells is their ability to deliver high performance without the hefty price tag often associated with precision instruments. Their innovative design allows for efficient manufacturing processes, leading to reduced production costs. As a result, businesses can invest in state-of-the-art measurement technology without compromising their budget, making these load cells an attractive option for companies looking to enhance their operational efficiency.

Moreover, the versatility of low profile load cells means they can be easily integrated into existing setups, further driving down costs associated with system modifications. With the ability to accommodate various load capacities and environmental conditions, these load cells offer the perfect solution for diverse engineering needs. As industries continue to prioritize precision and cost-effectiveness, low profile load cells are undoubtedly defining the future of measurement technology.

Comparative Analysis: Low Profile vs. Traditional Load Cells

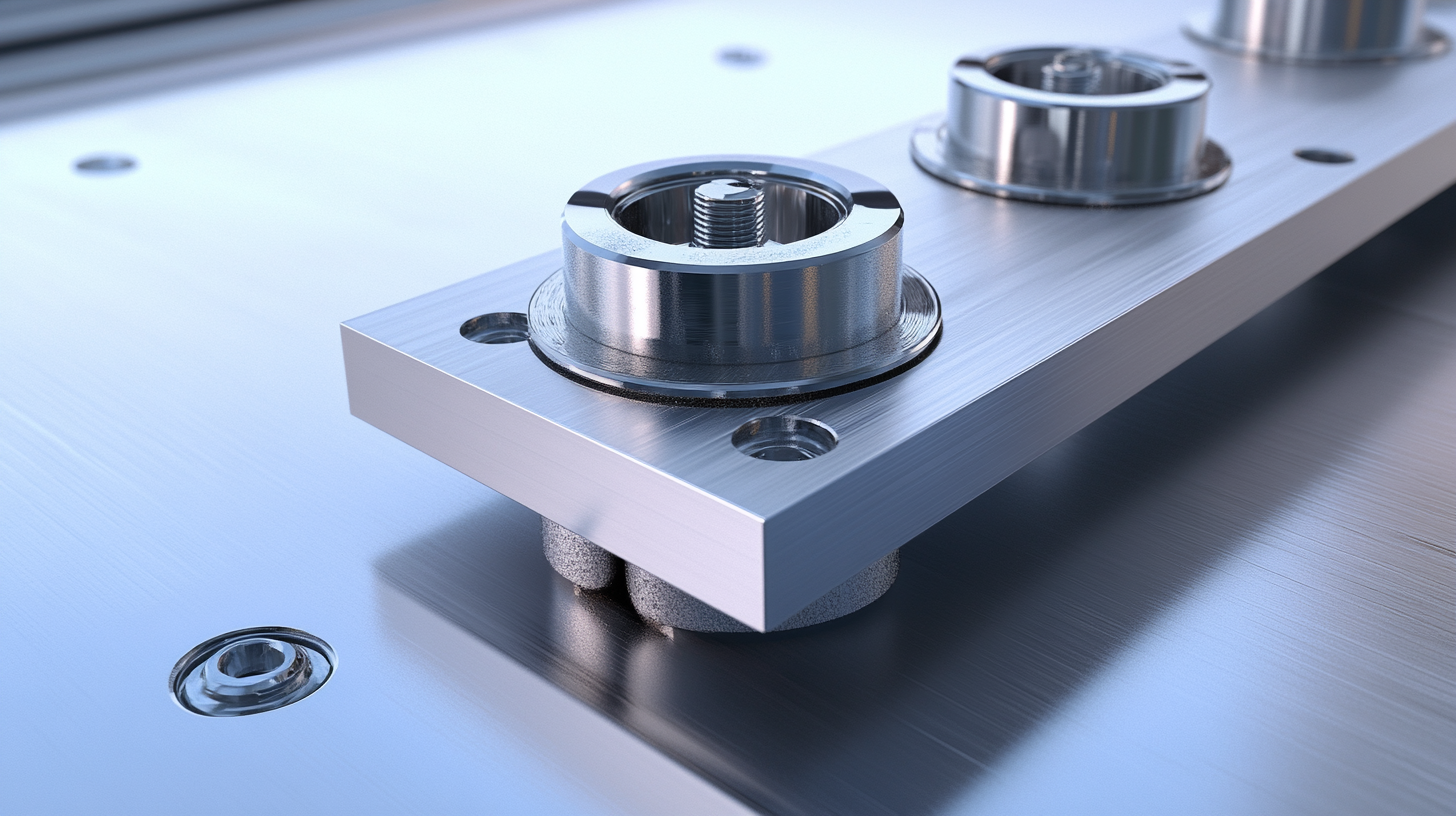

When it comes to precision measurement, choosing the right load cell is essential. Traditional load cells, while effective, tend to be bulkier and may introduce more variables into the measurement equation. In contrast, low profile load cells offer distinct advantages that can significantly enhance measurement accuracy and reliability. One of the primary benefits of low profile load cells is their superior compactness. Their slim design allows them to be easily integrated into tight spaces where traditional load cells might not fit, making them ideal for applications with limited room for equipment installation.

Another crucial factor in the comparative analysis is the mechanical stability offered by low profile load cells. These devices are designed to minimize errors caused by stress and bending moments, which can often affect the readings of traditional load cells. Their lower center of gravity not only improves their stability but also enhances their responsiveness to various loading conditions. This ensures that users receive consistent and accurate data, even in complex measurement environments.

Additionally, low profile load cells typically exhibit a greater tolerance for side loading. This characteristic is particularly important in dynamic applications where lateral forces can unintentionally influence the measurement. In contrast, traditional load cells may struggle to maintain accuracy under similar conditions. As industries continue to evolve and require more precise measurement solutions, the advantages of incorporating low profile load cells become increasingly evident, making them a superior choice for modern applications.