sales@loadcellsensor.com

sales@loadcellsensor.com

2026 Best Donut Load Cell for Accurate Weighing Solutions?

In the quest for precision in weighing, the Donut Load Cell emerges as a crucial technology. Experts, like Dr. Alice Thompson, highlight its importance with, "A Donut Load Cell can provide unmatched accuracy in various applications." This statement reflects the growing reliance on sophisticated weighing solutions in industries ranging from manufacturing to food processing.

The unique design of the Donut Load Cell allows for efficient force measurement. Its structure accommodates off-center loads and minimizes errors. Many industries face challenges with traditional load cells, often struggling with calibration and accuracy. The Donut Load Cell addresses some of these issues but not without limitations. For instance, its sensitivity can be affected by temperature changes, which can lead to inconsistent readings.

As we delve into the best options available in 2026, it’s essential to consider not just features, but also potential drawbacks. Not all Donut Load Cells are created equal. It’s crucial to evaluate their specifications and applications carefully. Innovations continue to shape this field, yet there’s a need for ongoing improvement and reflection on current designs.

What is a Donut Load Cell and How Does It Work?

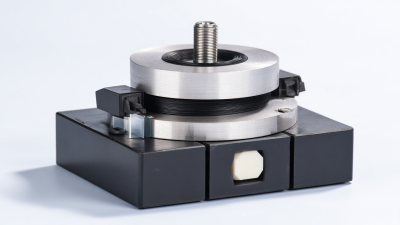

A donut load cell is a specialized sensor designed for precise weight measurement. Its unique shape allows for even weight distribution, making it ideal for dynamic applications like tension and compression testing. Reports from industry leaders indicate that donut load cells achieve 0.1% accuracy in optimal conditions. This makes them suitable for both heavy industrial use and delicate lab settings.

Operating on the principle of strain gauges, these cells convert mechanical stress into electrical signals. This conversion offers real-time data and ensures high accuracy. According to a recent market analysis, the demand for donut load cells has surged by 25% over the past three years. However, challenges remain. Environmental factors, such as temperature variance, can affect measurements. Users must calibrate devices regularly to maintain accuracy.

While donut load cells excel in various applications, they can present installation difficulties. Space constraints may hinder proper setup. Moreover, improper load alignment can lead to measurement errors. Industry professionals must consider these factors when choosing the appropriate load cell for specific tasks. Balancing precision and practicality requires careful planning and execution.

2026 Best Donut Load Cell Performance Analysis

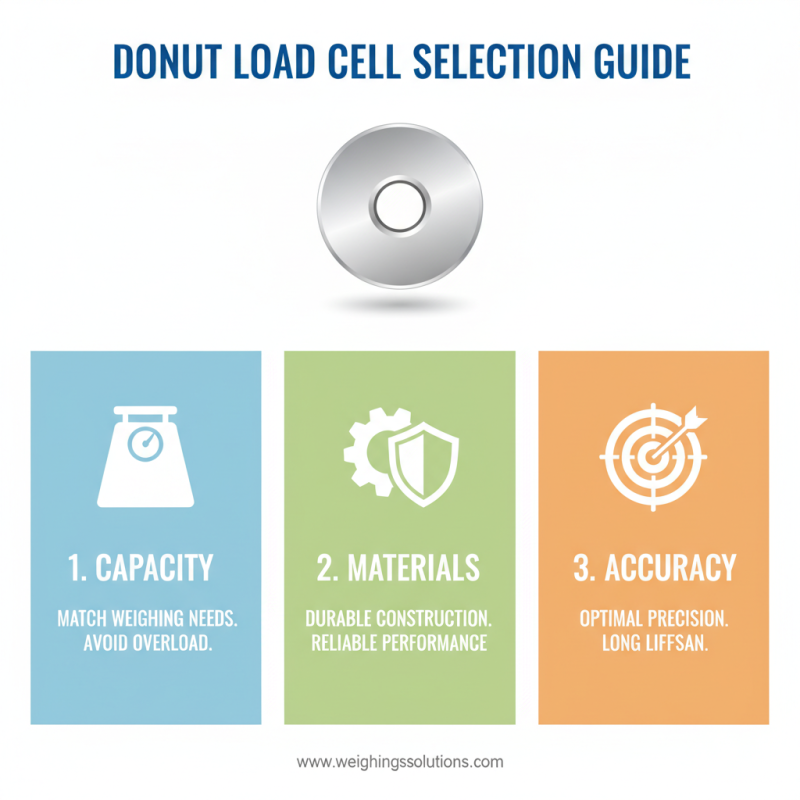

Key Features to Consider When Choosing a Donut Load Cell

When selecting a donut load cell for accurate weighing solutions, it's crucial to consider several key features. The load cell's capacity should match your weighing needs. Overloading can compromise accuracy and add wear. Check the materials used in construction. Durable materials ensure longevity and reliable performance.

Calibration is another vital factor. A well-calibrated donut load cell provides consistent measurements. Look for models that offer easy calibration options. This can save time and reduce errors in readings.

**Tips:** Always review the environment where the load cell will be used. Temperature and humidity can affect performance. Protection against dust and moisture is important. A rated IP protection level is ideal.

Lastly, evaluate the installation process. Complex setups can lead to complications. User-friendly designs are critical for seamless integration. If the load cell is hard to install, it might cause frustration later on. Remember, simplicity can enhance efficiency. Choose wisely for the best results.

Top Brands and Models for 2026 Donut Load Cells

In 2026, donut load cells are crucial for precise weighing solutions across various industries. These sensors excel in tension and compression applications. According to industry reports, accuracy levels can reach up to 0.01%. This precision is essential for manufacturers and laboratories that rely on exact measurements.

When selecting the best models, consider the maximum load capabilities. Many donut load cells have ranges from 500 to 10,000 pounds. However, not all models provide the same accuracy. It's worth noting that environmental factors can affect performance. For instance, temperature variations may introduce measurement errors.

User feedback often highlights the importance of calibration. Regular checks can help maintain the reliability of readings. Many users report issues with drift over time, which can skew results. Investing in a high-quality model may mitigate these problems. Don't underestimate the value of good installation practices to enhance performance.

Applications of Donut Load Cells in Various Industries

Donut load cells are gaining traction across various industries due to their unique design. With a circular shape, they provide exceptional accuracy in weighing, making them ideal for applications where precision is crucial. These load cells excel in environments with space constraints, fitting seamlessly into existing setups. Their reliability makes them popular in manufacturing, logistics, and even food processing.

In manufacturing, donut load cells ensure that product weights stay consistent. This minimizes material waste and enhances quality control. In logistics, they help maintain accurate shipping weights, preventing costly errors. The food industry benefits from these load cells as well. Accurate readings ensure proper ingredient measurements, impacting final product quality. However, integration with older systems can sometimes be challenging. Addressing compatibility issues is a task that can lead to unexpected delays.

Another aspect worth noting is the importance of regular calibration. Some users may overlook this, assuming that once set up, the load cells will remain accurate. Regular checks are essential for maintaining accuracy. While donut load cells are designed for durability, factors like temperature and wear can affect their performance. Being proactive about maintenance can mitigate these issues. Each industry has its nuances, and honing in on those can lead to better outcomes.

2026 Best Donut Load Cell for Accurate Weighing Solutions

| Industry | Application | Load Cell Capacity (kg) | Accuracy (%) | Features |

|---|---|---|---|---|

| Manufacturing | Material Testing | 500 | 0.02 | High precision, compact design |

| Food Industry | Portion Control | 200 | 0.05 | Hygienic design, moisture resistant |

| Pharmaceutical | Ingredient Weighing | 100 | 0.01 | Calibration options, low-profile structure |

| Logistics | Cargo Weighing | 1000 | 0.1 | Rugged design, easy installation |

| Construction | Structural Load Testing | 1500 | 0.05 | Robust, high load tolerance |

Comparison of Donut Load Cells with Other Load Cell Types

When it comes to weighing solutions, donut load cells stand out among various types. Their unique shape allows for better load distribution. This can reduce errors in measurements, especially with dynamic loads. Traditional load cells often have limitations in accuracy under certain conditions. A donut load cell navigates these challenges by providing robust and precise data.

Comparing donut load cells to beam or single point types, a few key differences emerge. Donut cells generally offer better stability. They are less sensitive to misalignment, which can skew results. This is essential in applications where precision is non-negotiable. However, not every situation requires the advantages of a donut load cell. They may be overkill for lightweight tasks.

Tip: Consider your specific application before choosing a load cell. Sometimes a simpler option suffices.

Despite their benefits, donut load cells are not universally superior. Their installation might be more complex, which could lead to errors. Regular maintenance and calibration are also crucial. Neglecting these aspects can result in significant inaccuracies over time. Balancing the pros and cons of each load cell type will lead to smarter choices.

Tip: Always assess the environment where the load cell will be used. This will inform your decision on the best type for your needs.

Related Posts

-

Unlocking Industry Potential with Strain Gauge Load Cells at the 2025 China Import and Export Fair

-

How to Choose the Right Wire Rope Load Cell for Your Needs?

-

Top Pancake Load Cell Applications in Industry and Science?

-

The Ultimate Guide to Sourcing High-Quality Suppliers for Best Button Type Load Cells

-

2025 How to Choose the Right Hollow Load Cell for Accurate Measurements

-

Understanding the Science Behind Torque Load Cells: Applications and Innovations