sales@loadcellsensor.com

sales@loadcellsensor.com

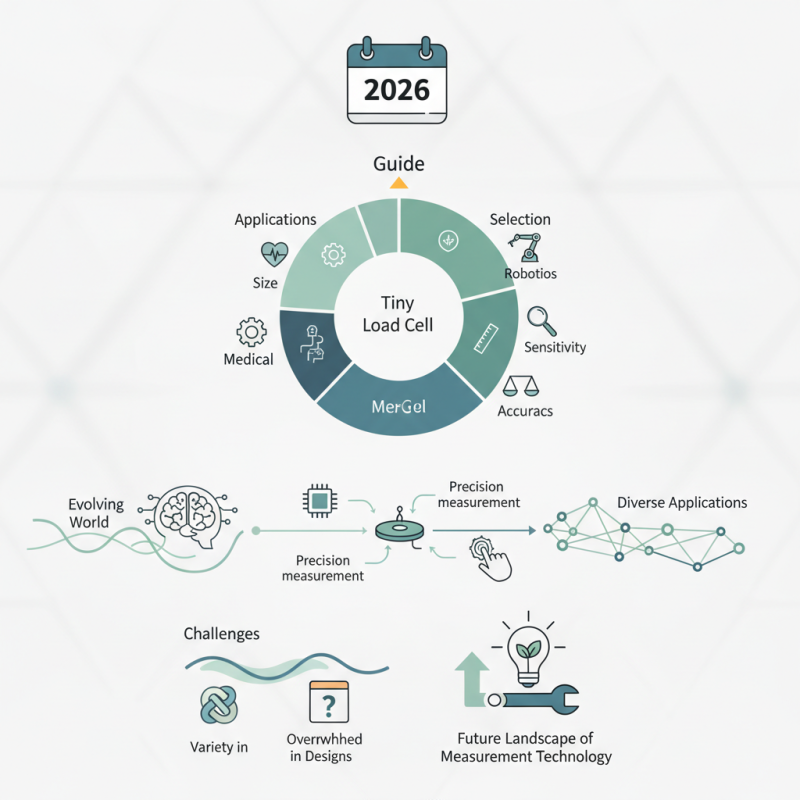

2026 Best Tiny Load Cell Applications and Selection Guide?

In the rapidly evolving world of precision measurement, Tiny Load Cells are gaining impressive traction. These compact sensors play a critical role in diverse applications, from medical devices to industrial automation. According to Dr. Emily Carter, a leading expert in sensor technology, "Tiny Load Cells are reshaping how we measure and interact with our environment." Her insights underline the importance of selecting the right load cell for each specific use.

The adoption of Tiny Load Cells is not without its challenges. While they offer unparalleled accuracy, the selection process can be overwhelming due to the variety in designs and specifications. For instance, choosing a load cell that fits both size and sensitivity requirements often demands careful consideration.

As applications grow, so do the expectations. Engineers and designers must reflect on their choices and the implications for performance. Crafting systems with Tiny Load Cells requires a balance between innovation and practicality. Understanding this balance will define the future landscape of measurement technology.

2026 Overview of Tiny Load Cells: Definition and Types

Tiny load cells are essential for precise measurements in various applications. These sensors convert force into an electrical signal, providing accurate weight readings. Their small size makes them ideal for compact devices, but it also presents challenges. Users must ensure proper installation, as misalignment can lead to errors.

There are several types of tiny load cells. Strain gauge load cells are common due to their sensitivity. Capacitive load cells offer good stability but can be affected by temperature changes. Choosing the right type is crucial; each has unique benefits and drawbacks. Evaluating the application requirements is essential to avoid potential issues.

Designers often overlook the importance of calibration. Without proper calibration, load cells may produce misleading results. It’s vital to regularly check the setup to maintain accuracy. The journey isn’t always smooth, and users should be prepared for adjustments along the way.

Key Specifications and Features of Tiny Load Cells for Selection

Tiny load cells are essential in various applications, including weighing, force measurement, and robotics. Their compact size allows integration into tight spaces where larger sensors would fail. Key specifications like capacity, precision, and temperature range significantly influence performance. For instance, load cells often range from a few grams to thousands of kilograms. Precision can vary from 0.1% to 0.01%, impacting the reliability of measurements in critical applications.

Another important feature is the output type. Load cells may provide analog or digital signals. Therefore, choosing the right output type for your system is crucial. Some systems might require a specific protocol, such as RS-232 or USB. Additionally, sensitivity to temperature changes is a consideration, as thermal drift can affect accuracy. According to recent industry reports, nearly 15% of load cell failures relate to environmental factors.

When selecting tiny load cells, consider overall dimensions and mounting options. Limited space might restrict options. Also, readjustment might be necessary in evolving setups. A load cell might need recalibration after installation. These factors highlight the importance of careful selection and regular maintenance.

Top Applications of Tiny Load Cells Across Various Industries

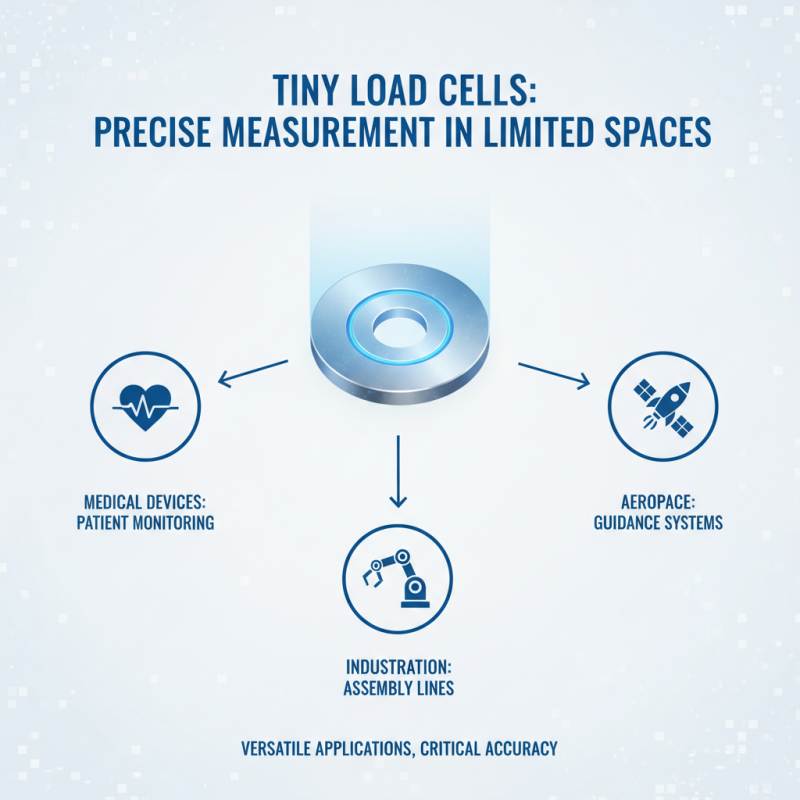

Tiny load cells have emerged as essential components in various industries, providing precise measurements in limited spaces. Their small size allows for versatility in applications like medical devices, industrial automation, and aerospace. In healthcare, they are used in patient monitoring systems where accuracy is critical. In manufacturing, they help in creating precise assembly lines.

For effective selection of tiny load cells, consider the environment. Will they face extreme temperatures or moisture? These factors can influence performance. The installation process can also be tricky. Ensure that the load cell fits snugly without any strain. Improper installation can lead to faulty readings.

Moreover, it’s crucial not to overlook calibration. A poorly calibrated load cell can significantly affect your data. Regular checks help maintain accuracy. If you notice erratic readings, it’s time to reassess. Testing and iterating on your setup can yield better results. Always question the reliability of your chosen load cell for ongoing projects.

Market Trends and Innovations in Tiny Load Cell Technology

Tiny load cells are becoming essential in various industries. Their compact size allows for integration into small devices. This trend has fueled innovations in design and functionality. Many applications are emerging, from portable electronics to industrial automation. The demand for precision and reliability drives this growth.

Market trends indicate a shift toward wireless technology. Many tiny load cells now feature Bluetooth connectivity. This allows for seamless data transmission. Users can monitor measurements in real time. However, this innovation brings challenges. Battery life can be a concern, especially in remote applications. Additionally, ensuring data security is crucial.

Recent advancements include improved materials that enhance durability. These materials withstand harsh environments, ensuring longevity. However, not all manufacturers prioritize quality. Some products may have hidden flaws. It’s vital to research and compare options. Understanding the limitatons and potential issues is crucial for a successful selection. Balancing innovation with practical application remains a constant challenge.

Factors Influencing the Selection of Tiny Load Cells in Engineering

Tiny load cells are increasingly popular in various engineering applications. Selecting the right load cell can be challenging. Several factors significantly influence this choice.

Accuracy is crucial. Some applications require very precise measurements, while others permit greater tolerance. Consider the load range too. It's essential to match the load cell capacity with the expected load. If the capacity is too low, it risks damage. Too high a capacity can lead to reduced sensitivity.

Environmental conditions can affect performance. Temperature changes contribute to measurement drift. Some tiny load cells might not be suitable for high humidity settings. Additionally, connection types matter. Welded connections may provide greater stability than soldered ones. Yet, maintenance for welded connections can be challenging. Always reflect on the specific requirements before finalizing the selection.

2026 Best Tiny Load Cell Applications

Related Posts

-

Understanding Import Export Certifications for Best Thin Load Cells with a Comprehensive Tutorial Guide

-

2025 How to Choose the Right Hollow Load Cell for Accurate Measurements

-

2026 Top Tension Compression Load Cell Trends and Innovations?

-

Top Strategies for Selecting the Best 5kg Load Cell for Your Business Needs

-

2026 How to Choose a 20kg Load Cell for Your Project?

-

Exploring Alternative Load Cell Solutions for Optimizing Tensile and Compressive Testing