sales@loadcellsensor.com

sales@loadcellsensor.com

How to Calibrate Your Load Cell 1kg for Accurate Measurements

Calibrating a Load Cell 1kg is essential for ensuring precision in weight measurement across various industries, including manufacturing and laboratory settings. According to a recent report by the International Society of Weighing Technology, accurate load cell calibration can enhance measurement reliability by up to 20%, significantly reducing errors that can lead to costly inefficiencies. Load cells, integral to various applications, function by converting force into an electrical signal, and their accuracy directly influences production quality and compliance with industry standards. Therefore, understanding the calibration process not only optimizes performance but also adheres to regulatory requirements, making it crucial for professionals who rely on these devices for their operations. Implementing proper calibration techniques for your Load Cell 1kg will guarantee that your measurements are consistent, reliable, and in alignment with both organizational goals and safety regulations.

Calibrating a Load Cell 1kg is essential for ensuring precision in weight measurement across various industries, including manufacturing and laboratory settings. According to a recent report by the International Society of Weighing Technology, accurate load cell calibration can enhance measurement reliability by up to 20%, significantly reducing errors that can lead to costly inefficiencies. Load cells, integral to various applications, function by converting force into an electrical signal, and their accuracy directly influences production quality and compliance with industry standards. Therefore, understanding the calibration process not only optimizes performance but also adheres to regulatory requirements, making it crucial for professionals who rely on these devices for their operations. Implementing proper calibration techniques for your Load Cell 1kg will guarantee that your measurements are consistent, reliable, and in alignment with both organizational goals and safety regulations.

Understanding the Basics of Load Cells and Their Functions

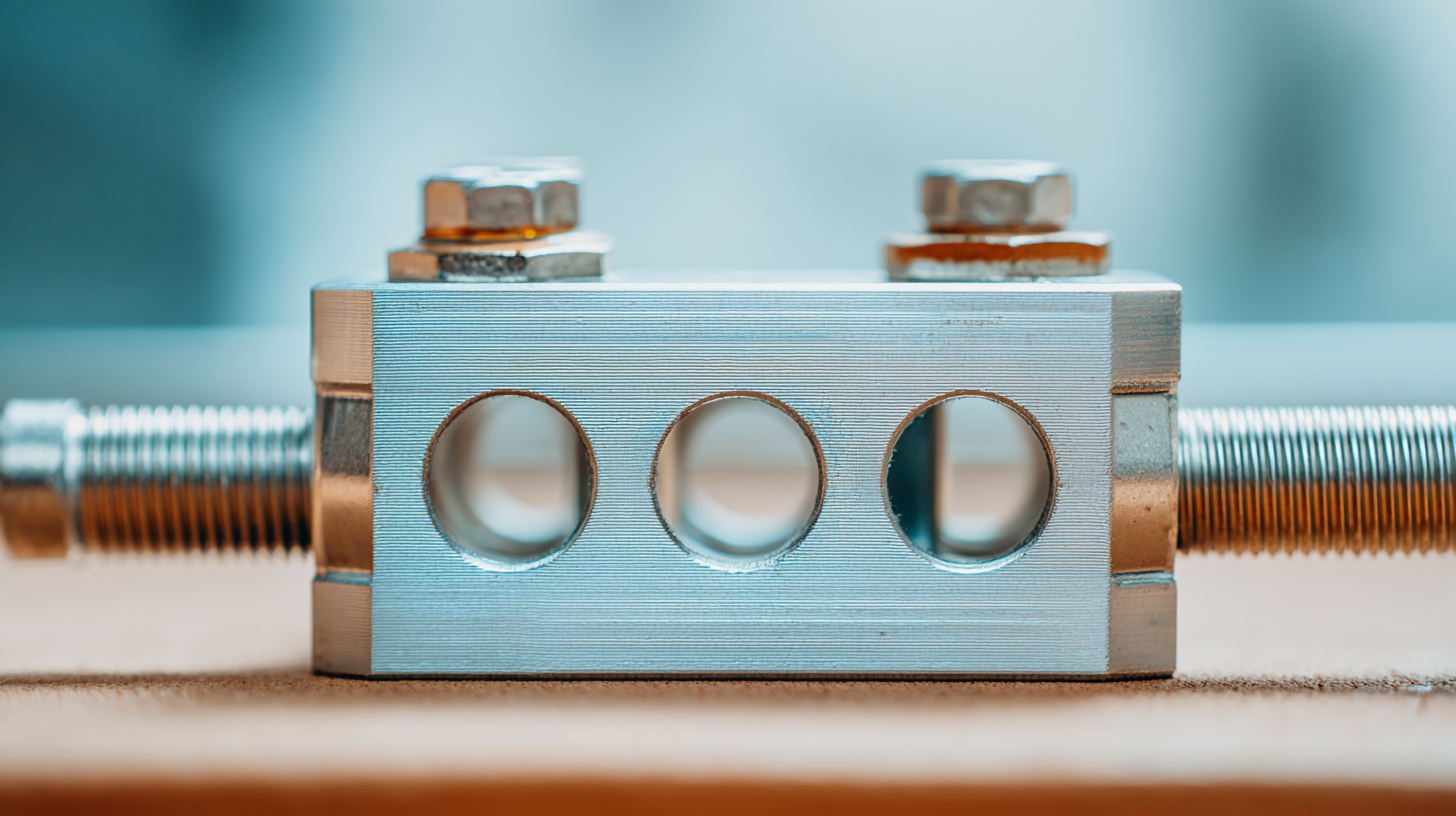

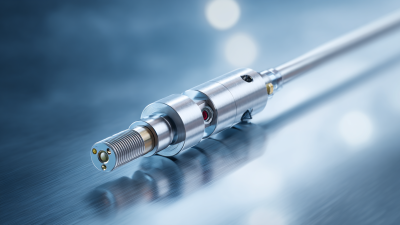

Load cells are essential devices used to measure weight or force in various applications, from industrial scales to electronic weighing systems. These sensors operate on the principle of converting mechanical force into an electrical signal. They typically consist of a metal element that deforms under load, with strain gauges attached to measure the deformation. Understanding how load cells function is crucial for ensuring accurate measurements, especially in precision applications.

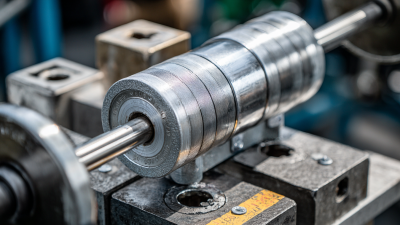

When calibrating a load cell, it is important to establish a clear understanding of its specifications and operating environment. Start by ensuring that the load cell is installed correctly and leveled. An uneven surface can lead to measurement errors. Additionally, using certified weights for calibration is vital to achieve the most accurate readings.

**Tips**: Always check for potential sources of interference, such as electromagnetic fields, which can affect the load cell’s performance. Regular maintenance and recalibration at predetermined intervals will help maintain accuracy over time. Document the calibration process meticulously to track any changes in performance, ensuring consistent reliability in your measurements.

Load Cell Calibration Data

This bar chart represents the calibration data of a 1kg load cell. The measurements were taken for different weights to verify the accuracy of the load cell's readings.

Identifying the Tools Required for Calibrating a 1kg Load Cell

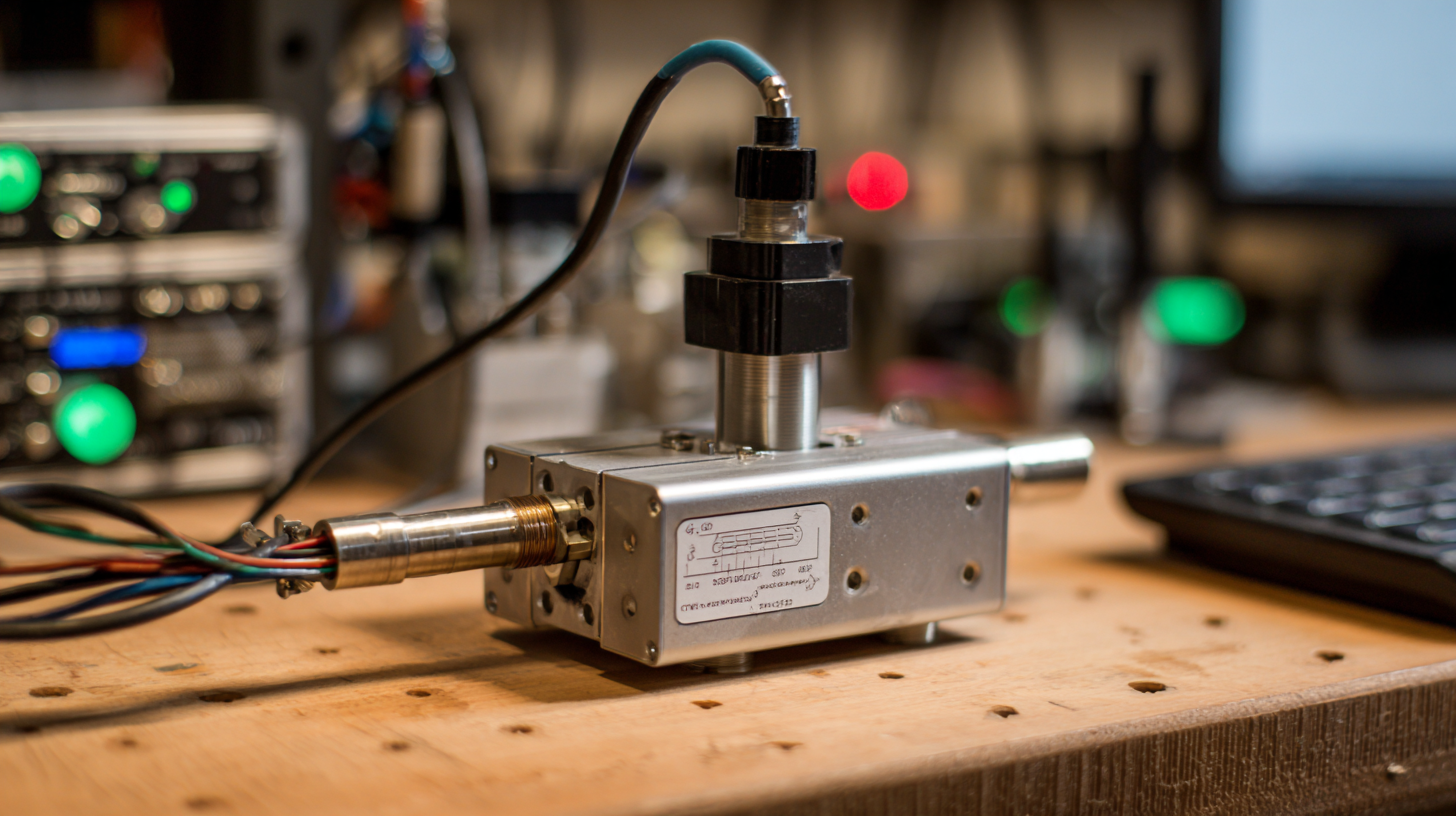

To effectively calibrate a 1kg load cell, it is crucial to gather the appropriate tools that will ensure precise measurements. First and foremost, a reliable digital multimeter is essential for evaluating the electrical output of the load cell. This device allows you to monitor resistance and voltage, providing a clear understanding of how the load cell performs under different weights. You will also need a calibration weight, specifically a certified 1kg weight, to ensure accuracy during the calibration process. Using a certified weight prevents discrepancies that could arise from using makeshift weights.

In addition to the primary tools, consider including a connection cable compatible with the load cell’s specifications. This will facilitate a stable connection during the calibration. Additionally, access to a computer with data acquisition software can greatly enhance the calibration process, allowing for real-time data visualization and adjustments. Lastly, having a precision scale can help verify measurements, ensuring the load cell’s outputs align perfectly with known weights. With these tools in hand, you can proceed confidently to calibrate your load cell for precise and reliable measurements.

How to Calibrate Your Load Cell 1kg for Accurate Measurements

| Tool | Description | Purpose |

|---|---|---|

| Digital Scale | A precise scale to measure the weight of calibration weights. | Used to verify the accuracy of the load cell measurements. |

| Calibration Weights | Standardized weights such as 1kg, 500g, etc. | Provides known values to calibrate the load cell. |

| Connecting Wires | Wires to connect the load cell to the measuring device. | Ensures accurate signal transmission from the load cell. |

| Multimeter | Device to measure electrical properties. | Used to check the electrical output from the load cell. |

| Software for Calibration | Computer application to input and adjust calibration data. | Facilitates accurate calibration adjustments and data recording. |

Step-by-Step Instructions for Setting Up Your Calibration Process

To successfully calibrate your 1kg load cell for precise measurements, follow these step-by-step instructions to set up your calibration process. First, gather the necessary tools, including a reliable digital scale, a known weight (preferably 1kg), and a multimeter to verify output readings. Ensure that the load cell is securely mounted in a stable environment to minimize external factors that could affect accuracy.

Next, start by connecting the load cell to your measurement system. Apply the known weight gradually, beginning with lighter weights and working your way up to 1kg. Record the readings displayed on your measurement system for each increment. It’s crucial to maintain consistent environmental conditions, such as temperature and humidity, during this process.

Once you have collected data, analyze the results by comparing the output readings of the load cell with the actual weights applied. Make any necessary adjustments to the calibration settings in your system software, ensuring the measurements align accurately with the known weights to achieve optimal performance.

Techniques for Testing and Verifying Calibration Accuracy

Calibrating a 1kg load cell is crucial for ensuring accurate measurements in various applications, from industrial scales to laboratory testing. To verify the calibration accuracy, several techniques can be employed. One of the most common methods is the use of known weights for testing. By applying calibrated weights close to the load cell's maximum capacity, you can observe if the readings correspond accurately. For instance, according to a report by the International Society of Automation, using certified calibration weights can reduce measurement deviations to under 0.2%, essential for high-precision applications.

Another effective technique for verifying calibration accuracy involves utilizing a multimeter in conjunction with the load cell. By measuring the output voltage and comparing it against expected values based on the applied load, discrepancies can be identified. Research from the National Institute of Standards and Technology shows that incorporating digital multimeters can enhance measurement reliability, offering an accuracy level of 0.1% or better. Additionally, routine checks with these instruments can help ensure long-term reliability and performance of the load cell, making them indispensable tools in the calibration process.

Common Issues and Troubleshooting Tips During Calibration

Calibrating a 1kg load cell is crucial for ensuring accurate measurements in various applications, from industrial scales to laboratory experiments. However, several common issues can arise during the calibration process. One prevalent problem is temperature fluctuations, which can affect the sensor's performance. Research indicates that load cells can experience a sensitivity change of up to 0.1% for every degree Celsius variation. To mitigate this, it’s advisable to conduct calibrations in a controlled environment where temperature remains stable.

Another frequent challenge is the presence of mechanical stress that may distort readings. Overloading can lead to permanent damage, while even slight misalignments can produce inconsistent results. Data from the National Institute of Standards and Technology (NIST) underscores that maintaining proper mounting and alignment can enhance accuracy by roughly 0.5%.

Tips: Before commencing calibration, ensure that the load cell is properly zeroed, and verify that no external forces are acting on it. Additionally, using certified weights that are traceable to national standards can significantly enhance the reliability of your measurements. Regular maintenance and routine recalibration every six months can also prevent discrepancies in measurements.

Related Posts

-

How to Choose the Perfect Thin Load Cell for Your Industrial Applications

-

Exploring the Future of Load Cells: Innovations Beyond the Best Bending Beam by 2025

-

Navigating the 2025 Technology Trends in Load Cells Your Ultimate Guide to Best Miniature Load Cells

-

Overcoming Industry Standards: How to Choose the Best Compression Load Cell Amidst Common Challenges

-

Discovering the Best Compression Load Cells: A Global Buyer’s Guide for Performance and Reliability

-

7 Unique Benefits of Compression Type Load Cells for Modern Industries