sales@loadcellsensor.com

sales@loadcellsensor.com

2026 How to Choose a 20kg Load Cell for Your Project?

Choosing the right 20kg Load Cell for your project is crucial. This component plays a vital role in measuring weight accurately. Various factors come into play when selecting the best one. The specifications can vary widely; thus, doing thorough research is important.

You should consider the application of the load cell. Will it be exposed to harsh environments? Understanding the conditions it will operate in helps narrow down options. Some load cells excel in specific scenarios. However, not every model fits all needs, creating a dilemma.

Pay attention to calibration and accuracy. An inaccurate load cell can lead to significant errors. This could impact your project's success. Sometimes, personal biases affect our choices. Reflect on what you truly need from a 20kg Load Cell. An informed decision requires careful thought and analysis.

Understanding Load Cells: Types and Functions

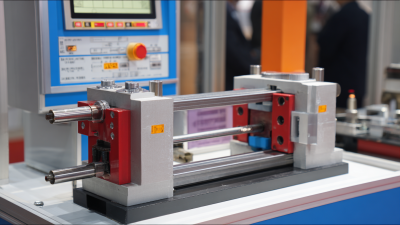

Load cells are essential components in many measurement applications. They convert a force into an electrical signal. This signal can be used to determine weight or pressure. There are different types of load cells, each with distinct functions. Understanding these types is crucial for your project.

Strain gauge load cells are popular in industrial applications. They offer high accuracy and are cost-effective. However, they can be sensitive to temperature changes. This might lead to errors in measurement.

On the other hand, pneumatic load cells use air pressure to measure force. They are typically less affected by environmental factors. But they may require more setup and calibration.

Choosing the right load cell involves understanding your specific needs. Think about capacity, accuracy, and environmental conditions. For instance, if you need to measure heavy loads, a 20kg load cell might work well. But, if you require high precision, consider other types. Always reflect on the limitations of each type. It’s not just about picking any load cell; it’s about finding the best fit for your project.

Key Specifications to Consider in a 20kg Load Cell

When selecting a 20kg load cell, it’s essential to consider several key specifications. Sensitivity is crucial; it dictates how effectively the load cell converts force into a measurable output. A typical sensitivity range is around 1-2 mV/V. This means that for every volt applied, the output will reflect the load proportionally. A higher sensitivity often provides better accuracy, but it can also be more fragile under extreme conditions.

Load cells come with various options regarding their dimensions. The size can affect how easily they fit into your project. Some designs are compact, optimizing space, while others are bulkier. This decision should reflect your project needs. Additionally, consider environmental factors. Will the load cell face moisture, dust, or temperature variations? Choosing a model with proper environmental sealing is crucial for durability.

Wiring configurations also play a role in functionality. Commonly, load cells are available in different output types, such as analog or digital. Depending on your project's electrical setup, one type may suit your needs better than the other. But remember, the installation can sometimes be complex. Having a proper guide is essential, as incorrect wiring can lead to misreadings and inaccurate results. Each aspect requires thought and careful consideration to ensure a successful application.

2026 Load Cell Specifications Analysis

Factors Influencing Load Cell Accuracy and Sensitivity

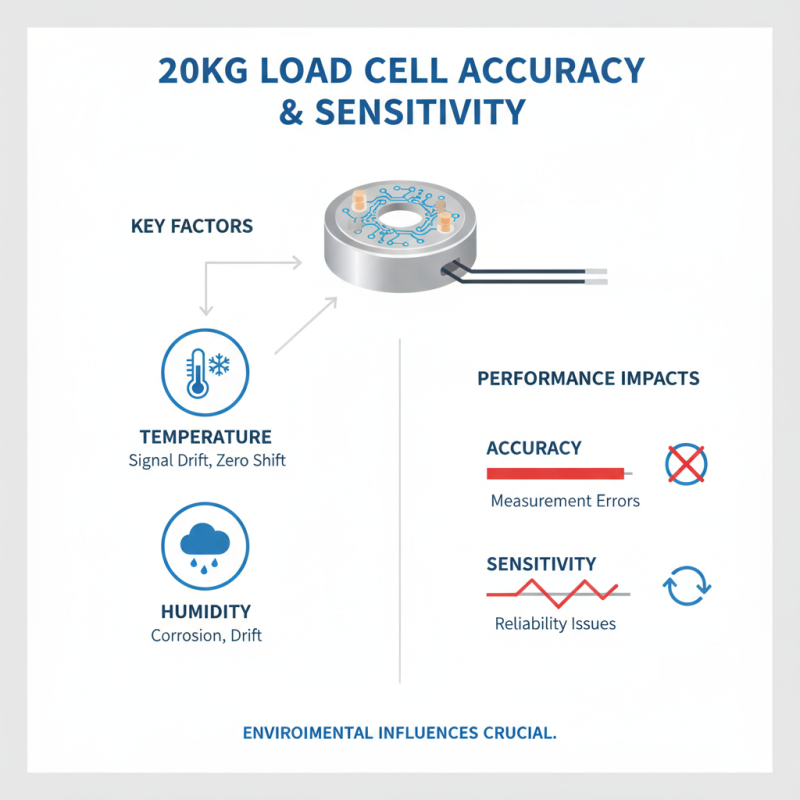

When selecting a 20kg load cell, understanding factors influencing accuracy and sensitivity is crucial. Load cell performance can heavily depend on environmental conditions like temperature and humidity. Variations in these factors can lead to measurement errors. For instance, a load cell used in a humid environment may experience signal drift, affecting its reliability.

Tips: Regular calibration can help minimize errors caused by environmental changes. Ensure that the load cell is calibrated according to the manufacturer's guidelines to maintain accuracy over time.

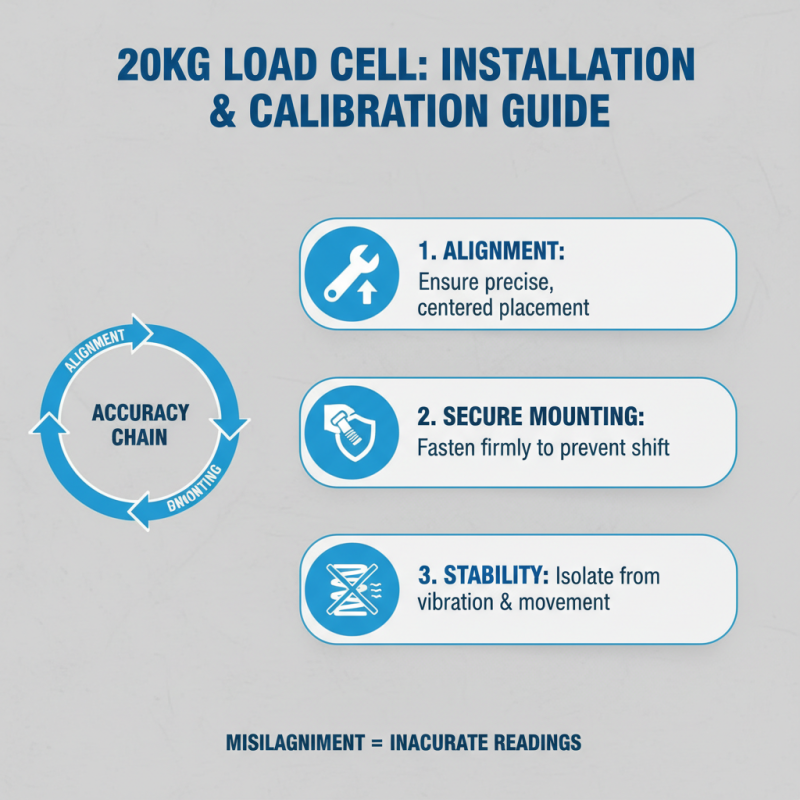

Another significant factor is the installation process. Improper mounting can introduce unwanted stress or misalignment, impacting the cell's sensitivity. Even a slight tilt can distort readings. Pay attention to how the load cell interacts with its surrounding structures during installation.

Tips: Use precision tools to mount the load cell accurately. Checking alignment is often overlooked but essential for optimal performance.

Lastly, choosing the right materials for the load cell can influence both its lifespan and sensitivity. Some materials may corrode or degrade faster in certain conditions. This can lead to inconsistent readings over time.

Tips: Research materials that suit your specific application. A mismatch could cost you in the long run.

Installation and Calibration Tips for Load Cells

When working with load cells, proper installation and calibration are crucial. A 20kg load cell often needs precise alignment. Misalignment can lead to inaccurate readings. Ensure that the load cell is mounted securely. Vibration can cause errors. Keep the surrounding area stable to maintain accuracy.

For calibration, it's essential to apply known weights. Start with a weight close to the load cell's capacity. Gradually increase to full load. Watch how the readings respond. It’s common to notice inconsistencies. Take time to document every step. This helps identify patterns or errors during calibration.

Don't overlook environmental factors. Temperature changes can impact readings. If the load cell operates in varying conditions, consider compensating for these fluctuations. Regular checks are also necessary. Recalibration may be required after significant use or environmental changes. Maintain a consistent method to ensure reliable data.

Common Applications of 20kg Load Cells in Industries

Load cells are essential components in various industries. A 20kg load cell is often used in manufacturing and packaging. In food processing, these sensors help ensure the accuracy of weigh-in systems. Workers depend on them to measure ingredient quantities precisely. A small error here can lead to significant problems in production.

In retail, load cells play a crucial role in electronic scales. They are used to weigh products for customers. Accurate readings enhance customer satisfaction. However, not all load cells deliver consistent results. Sometimes they need recalibration. This requires an understanding of the technology involved. Miscommunication can lead to frustration.

In construction, load cells are utilized to monitor heavy loads. They ensure that cranes and other equipment do not exceed capacity. Safety is paramount, yet sometimes these systems fail. Regular testing is necessary to prevent accidents. A single oversight could have serious consequences. Thus, attention to detail is crucial in choosing and maintaining load cells.

Related Posts

-

2025 How to Choose the Right Hollow Load Cell for Accurate Measurements

-

Common Issues Faced When Using Best Small Load Cells

-

Top 5 Micro Load Cells for Accurate Measurement in Industrial Applications

-

How to Maximize Efficiency in Your Operations with Bending Beam Load Cells

-

Unlocking Industry Potential with Strain Gauge Load Cells at the 2025 China Import and Export Fair

-

Understanding the Science Behind Torque Load Cells: Applications and Innovations