sales@loadcellsensor.com

sales@loadcellsensor.com

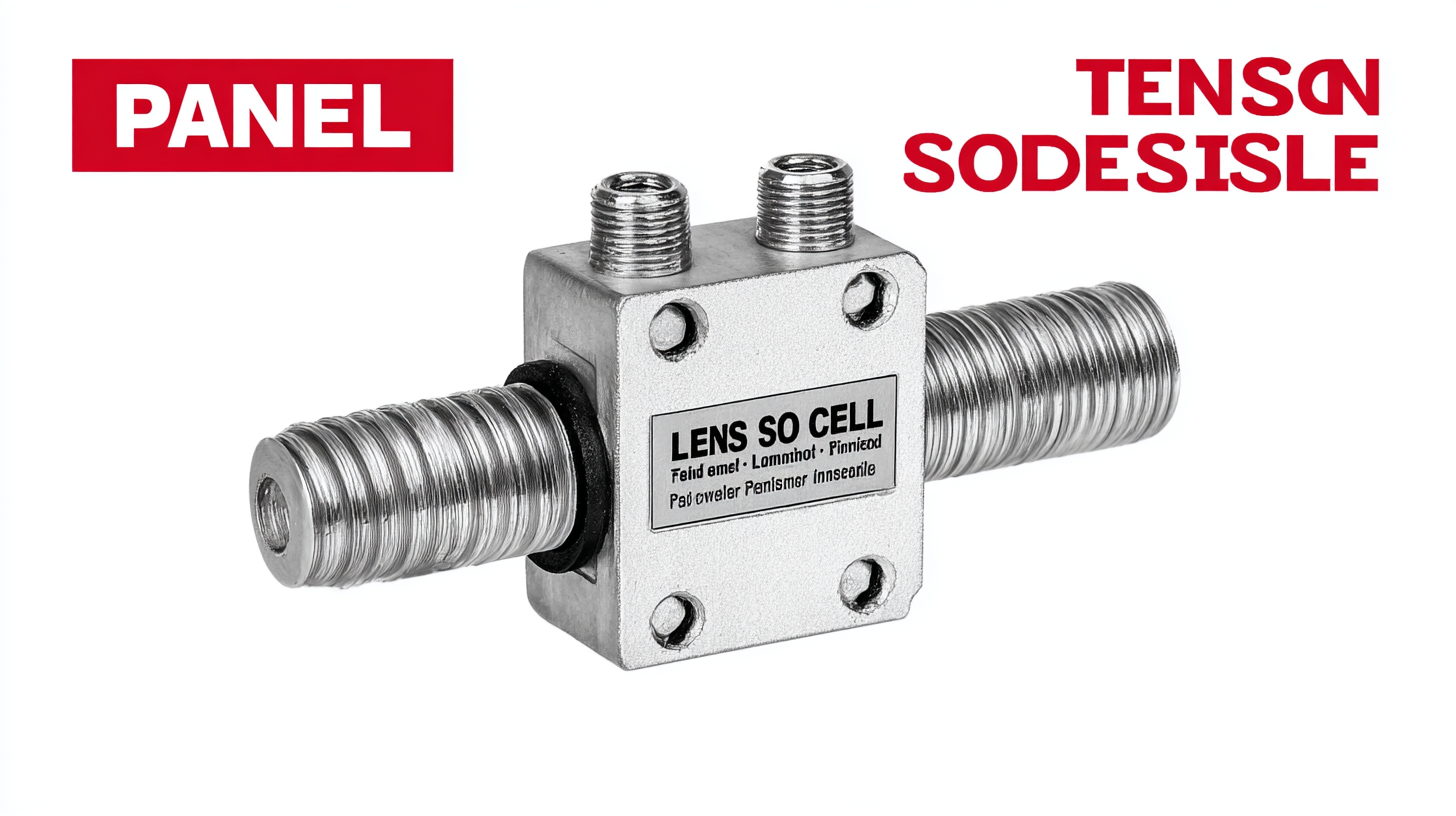

How to Choose the Best Tension Load Cell for Your Industrial Applications

In today's industrial landscape, accurate measurement of force and tension is crucial for ensuring operational efficiency and safety. One key component in achieving this precision is the Tension Load Cell, a versatile sensor designed to measure tension force in various applications. Whether you are involved in manufacturing, construction, or logistics, selecting the right Tension Load Cell can significantly impact your productivity and data integrity. This guide will provide essential insights into the factors to consider when choosing a Tension Load Cell, including the specific requirements of your application, environmental conditions, and accuracy levels needed. By understanding these elements, you can make an informed decision that not only meets your operational needs but also enhances overall performance in your industrial processes.

Understanding Tension Load Cells: Types and Applications in Industry

Tension load cells are essential components in various industrial applications, providing precise measurements of tensile forces. These sensors are predominantly classified into different types, such as strain gauge load cells, piezoelectric load cells, and capacitive load cells. According to a recent market research report by MarketsandMarkets, the global load cell market is projected to reach USD 4.1 billion by 2025, reflecting a CAGR of 5.8% from 2020. This growth is driven by the escalating demand for accurate and reliable measurements in industries such as manufacturing, logistics, and aerospace.

In industrial environments, tension load cells are employed for a range of applications, including weighing, material testing, and structural monitoring. For example, in the manufacturing sector, they play a crucial role in ensuring product quality by monitoring string tension during the production process. A study published by Research and Markets indicates that up to 70% of manufacturing plants have adopted load cell technology to enhance operational efficiency and minimize downtime. As industries increasingly prioritize automation and precision, understanding the different types of tension load cells and their specific applications becomes vital for selecting the best option for any given process.

Key Certifications for Importing and Exporting Tension Load Cells

When selecting tension load cells for industrial applications, understanding the key certifications for importing and exporting these devices is crucial, especially in light of recent trade regulations. Vietnam's trade ministry has enacted measures to combat illegal transhipment of goods, particularly concerning exports to the United States. This situation underscores the importance of ensuring that load cells comply with international standards and certifications to avoid issues that may arise from fraudulent activities.

Furthermore, with rising tensions in global trade, many countries are tightening their regulations, which can lead to increased scrutiny of imported goods. Certifications such as ISO, CE, and RoHS can serve as indicators of quality and compliance, providing both exporters and importers with a framework to navigate the complexities of international trade. As businesses increasingly rely on these technologies, ensuring that their tension load cells meet the necessary certifications will not only facilitate smoother transactions but also enhance the integrity and reliability of their industrial operations.

How to Choose the Best Tension Load Cell for Your Industrial Applications

| Load Cell Type | Max Capacity (kg) | Standard Deviation (± %) | Operating Temperature (°C) | Key Certifications |

|---|---|---|---|---|

| Tensile Load Cell | 500 | 0.05 | -20 to 60 | ISO 9001, OIML R60 |

| Compression Load Cell | 1000 | 0.03 | -30 to 70 | CE, RoHS |

| S-type Load Cell | 2000 | 0.02 | -20 to 80 | NTEP, FCC |

| Multi-Component Load Cell | 300 | 0.04 | -10 to 50 | ASME, ISO 17025 |

Factors to Consider When Selecting the Right Tension Load Cell

When selecting the right tension load cell for industrial applications, several critical factors must be considered to ensure optimal performance. Firstly, understanding the load cell's capacity is essential. Load cells come in various capacities, so it’s important to choose one that can handle the expected load without reaching its limits. This not only enhances accuracy but also extends the lifespan of the device. Additionally, consider the environmental conditions where the load cell will be deployed. Factors such as temperature, humidity, and exposure to chemicals can significantly affect performance, necessitating the selection of a load cell that can withstand such conditions.

Another important factor is the calibration and accuracy of the load cell. Regular tensile testing is crucial for maintaining not only the reliability of the load cell but also the quality of the materials being measured. Frequent calibration ensures that the load cell remains precise over time, thus aligning with industry standards. Moreover, the design and installation of the load cells should facilitate ease of integration into existing systems. With the global tension control market expanding rapidly, making informed choices regarding tension load cells can lead to improved operational efficiency and reduced costs across industrial applications.

Choosing the Best Tension Load Cell: Factors to Consider

This bar chart compares three hypothetical tension load cells based on factors like capacity, accuracy, temperature range, material, and price. These factors are crucial while selecting the appropriate tension load cell for industrial applications.

Best Practices for Integrating Tension Load Cells in Industrial Settings

Integrating tension load cells into industrial applications is essential for precise measurement and control. The best practices for this integration begin with selecting the appropriate load cell based on your specific needs. Factors such as capacity, accuracy, and environmental conditions play crucial roles in this decision. Moreover, ensuring compatibility with existing systems and considering the operational demands can significantly enhance performance. Adopting standardized protocols for installation and calibration further ensures that the tension load cells function optimally.

In addition to selection and installation, continuous monitoring and maintenance are vital for long-term success. This includes regular checks for any signs of wear or malfunction and recalibrating the load cells as necessary. Implementing advanced technology, such as automation and IoT solutions, can facilitate real-time data collection and analysis, contributing to improved efficiency and sustainability in industrial settings. As industries evolve, embracing these best practices not only enhances operational performance but also aligns with emerging trends in sustainable practices, highlighting the importance of responsible resource management.

Compliance Standards and Regulations for Tension Load Cell Usage

When selecting tension load cells for industrial applications, compliance with relevant standards and regulations is paramount. Load cells must adhere to the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI) guidelines, which dictate the testing and performance criteria for load measuring devices.

According to a report by the International Society of Automation (ISA), nearly 60% of industrial mishaps are attributed to non-compliance with these standards, underscoring the importance of careful selection.

Moreover, specific industry sectors have additional regulations. For example, in the food and pharmaceutical industries, tension load cells must meet the guidelines set forth by the Food and Drug Administration (FDA) and Good Manufacturing Practices (GMP). A study published by the National Institute of Standards and Technology (NIST) showed that compliance with these guidelines not only ensures product safety but also enhances the reliability of measurements, with accuracy variances reduced to less than 0.5% in certified devices. Thus, when contemplating a tension load cell, ensuring compliance is not just a regulatory necessity but a fundamental aspect of operational integrity.