sales@loadcellsensor.com

sales@loadcellsensor.com

10 Essential Tips for Choosing the Right Disc Load Cell for Your Applications

When it comes to selecting the right equipment for your weighing and measurement applications, the significance of choosing the appropriate Disc Load Cell cannot be overlooked. These essential components are integral to various industries, playing a crucial role in ensuring accuracy and reliability in weight measurement. However, the variety of options available can be overwhelming, making it essential to understand how to make an informed decision that aligns with your specific needs.

In this guide, we will explore ten essential tips that will streamline the process of selecting the ideal Disc Load Cell for your applications. Each tip focuses on critical factors such as load capacity, environmental conditions, and sensitivity levels, equipping you with the knowledge necessary to navigate the challenges of weight measurement equipment selection. By the end of this article, you will have a clearer understanding of the considerations to keep in mind, ensuring that your choice enhances productivity and minimizes error.

Key Factors to Consider When Selecting a Disc Load Cell for Your Application

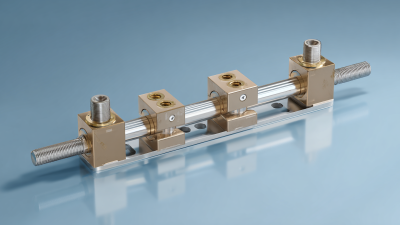

When selecting a disc load cell for your specific application, several key factors come into play. First and foremost, understanding the load capacity is crucial. It determines the maximum weight the load cell can accurately measure without risking damage or providing incorrect readings. Different applications require varying load capacities, so it's essential to choose a cell that matches or exceeds your requirements.

Another vital consideration is the environmental conditions in which the load cell will be used. Factors such as temperature, humidity, and exposure to corrosive substances can significantly impact performance and longevity. Choosing a load cell that is designed for your operational environment, such as those with protective coatings or suitable materials, can enhance reliability and accuracy. Additionally, consider the installation and mounting requirements; some designs offer more flexibility in integration, which can streamline the setup process in constrained spaces. By carefully evaluating these factors, you can ensure optimal performance and durability for your application.

Load Cell Selection Factors

This chart represents the importance level of key factors to consider when selecting a disc load cell for your application. The scale is from 1 to 10, with higher values indicating greater importance.

Understanding Different Types of Disc Load Cells and Their Applications

When selecting the right disc load cell for specific applications, it's essential to understand the various types available and their distinct functionalities. Disc load cells are commonly used in applications requiring precision measurement, such as rail scales, conveyor systems, and laboratory testing. According to a recent report from the International Society of Automation, approximately 45% of industrial load measurement applications utilize load cells, with disc types being favored for their compact design and high accuracy, typically offering precision levels better than ±0.05% of full scale.

Different types of disc load cells, such as tension, compression, and dual-ended shear beam load cells, provide unique advantages tailored to particular operational environments. For instance, a study by the American Society of Mechanical Engineers indicates that tension disc load cells are preferred in applications such as weighing and monitoring materials during construction, where dynamic load variations require swift and accurate data. Furthermore, with advancements in digital signal processing, the integration of disc load cells into IoT systems is on the rise, enhancing real-time monitoring capabilities and predictive maintenance strategies across various sectors, including manufacturing and logistics. This shift towards smarter systems emphasizes the importance of selecting the right load cell to meet not only current needs but also future scalability in industrial applications.

10 Essential Tips for Choosing the Right Disc Load Cell for Your Applications

| Type of Disc Load Cell | Maximum Capacity (kg) | Output Signal (mV/V) | Height (mm) | Material | Application |

|---|---|---|---|---|---|

| Standard Disc Load Cell | 500 | 2.0 | 30 | Aluminum | Industrial Weighing |

| High Precision Disc Load Cell | 1000 | 3.0 | 25 | Stainless Steel | Laboratory Testing |

| Heavy Duty Disc Load Cell | 3000 | 2.5 | 40 | Alloy Steel | Construction Weighing |

| Compact Disc Load Cell | 300 | 1.5 | 20 | Aluminum | Portable Applications |

| Explosion Proof Disc Load Cell | 2000 | 4.0 | 35 | Stainless Steel | Hazardous Locations |

Evaluating Accuracy and Precision Requirements for Load Cell Selection

When selecting the right disc load cell for your applications, one of the most critical factors to consider is the evaluation of accuracy and precision requirements. Understanding the specific needs of your application is essential, as different load cells have varying specifications that can impact their performance. Accuracy refers to how close the measurement is to the true value, while precision indicates the repeatability of the measurements under the same conditions. Both parameters must align with your operational objectives to ensure reliable data collection.

To evaluate these requirements effectively, start by analyzing the operational conditions in which the load cell will be used. Consider factors such as the load range, environmental conditions, and potential interferences. High-precision applications, such as those in laboratory settings, may necessitate load cells that offer tighter tolerances and higher resolution. Conversely, applications that prioritize durability over high precision may choose load cells with greater robustness, even if they compromise on measurement detail. By carefully assessing these aspects, you can select a disc load cell that meets both accuracy and precision needs, ensuring optimal performance in your application.

Exploring Environmental Considerations for Disc Load Cell Use

When selecting a disc load cell, environmental considerations play a crucial role in ensuring optimal performance and longevity. Disc load cells are often used in various settings, from industrial facilities to research laboratories, where they may be exposed to harsh conditions. Factors such as temperature variations, humidity levels, and the potential for exposure to dust, chemicals, or moisture should be carefully evaluated. Choosing load cells with the appropriate environmental ratings, such as IP67 or NEMA classifications, can help protect against these external threats and maintain accurate measurements.

Furthermore, installation location is another significant aspect to assess. The load cell should be positioned in a way that minimizes exposure to vibrations and mechanical shocks, which can adversely affect measurement precision. Adequate shielding from electromagnetic interference is also vital, particularly in environments with heavy machinery or electronic equipment. By taking these environmental factors into account, you can enhance not only the reliability of the disc load cell but also ensure that it meets all operational demands throughout its service life.

Cost vs. Performance: Balancing Budget with Load Cell Specifications

When selecting a disc load cell, balancing cost and performance is crucial for achieving optimal results in various applications. A recent industry report highlights that the overall expenditure on load cells can represent a significant portion of operational costs, with leading manufacturers indicating that high-quality load cells can range from $500 to $3,000 each, depending on specifications and performance. Understanding this investment is vital; for instance, a well-engineered load cell can improve accuracy by up to 0.01% over cheaper alternatives, which can yield significant savings in production efficiency and material usage in the long run.

However, performance should not be compromised for a lower initial cost. Choosing a load cell that meets precise application requirements—such as load range, environmental conditions, and the necessary accuracy—is essential. According to a study by TechSci Research, the global load cell market is expected to reach USD 2.55 billion by 2025, underscoring the growing acknowledgment of performance over price alone. Mitigating risks associated with inadequate load cell specifications can lead to increased operational reliability and longevity, justifying a higher upfront investment in quality to ensure that performance and cost are aligned efficiently.

Related Posts

-

Exploring the Use of Thin Load Cells in Heavy Machinery and Challenges Faced in Precision Measurements

-

Top 10 Micro Load Cell Manufacturers from China at the 137th Canton Fair

-

How to Maximize Efficiency in Your Operations with Bending Beam Load Cells

-

Common Issues Faced When Using Best Small Load Cells

-

What is a Thin Load Cell and How Does It Improve Measurement Accuracy?

-

Advantages of Utilizing Ring Load Cells for Precise Industrial Measurements