sales@loadcellsensor.com

sales@loadcellsensor.com

Exploring the Future of Load Cells: Innovations Beyond the Best Bending Beam by 2025

As we look towards 2025, the load cell industry is on the cusp of significant transformation, driven by advances in technology and innovative design approaches. Bending beam load cells, traditionally favored for their accuracy and reliability in diverse applications, are now being reimagined alongside emerging alternatives. According to the latest market research from ResearchAndMarkets, the global load cell market is expected to reach USD 3.9 billion by 2025, with a compound annual growth rate (CAGR) of 4.7% during the forecast period. This growth is fueled by increasing automation in various sectors, from manufacturing to healthcare, where precise weight measurement is critical. As we explore the future of load cells, it is imperative to examine how innovations beyond the conventional bending beam load cell can enhance performance, efficiency, and adaptability in measuring technologies.

Future Innovations in Load Cell Design and Materials by 2025

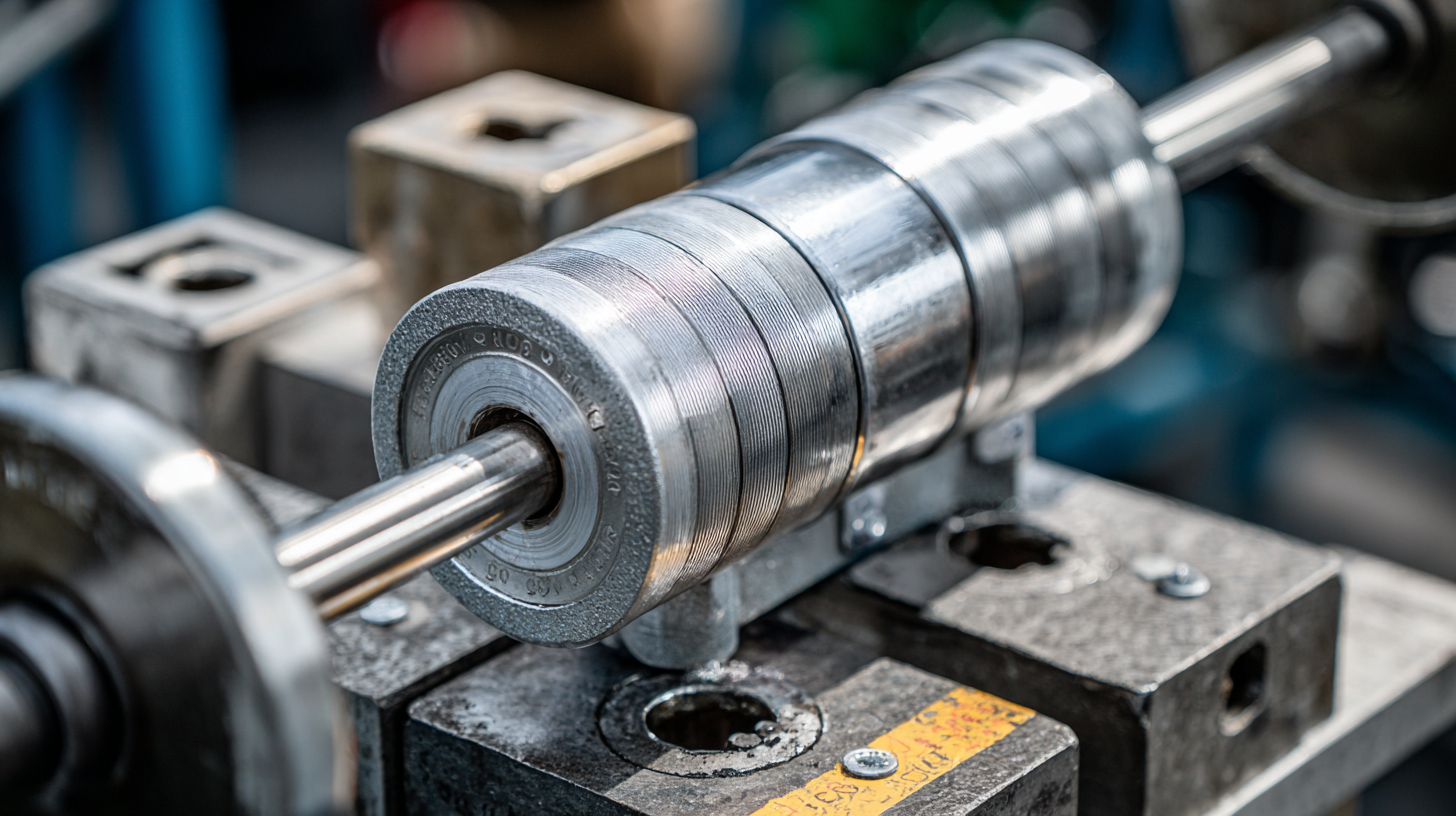

The exploration of load cell design and materials is entering an exciting era, particularly with advancements projected through 2025. Innovations in sensor technology are at the forefront of this evolution, underpinning a myriad of intelligent applications across industries. The Future Today Strategic Group’s 2025 Frontier Technology Trends report highlights significant shifts, particularly in materials like quantum dots and smart composites that promise enhanced performance in load cells. These advancements not only improve the accuracy of measurements but also broaden their applicability in various sectors, including automotive and manufacturing.

Tip 1: Keep an eye on hybrid materials that blend traditional sensor technologies with modern solutions. This approach is likely to yield load cells that are lighter, more sensitive, and resilient to environmental fluctuations.

Moreover, development in artificial intelligence and the Internet of Things (IoT) is set to revolutionize the functionality of load cells. By integrating these technologies, we anticipate smarter load cells that can provide real-time analytics and predictive maintenance solutions, thus optimizing the operational efficiency of machines and vehicles alike.

Tip 2: Consider utilizing data analytics to track load cell performance over time. This proactive strategy can help in identifying potential issues before they escalate, ensuring uninterrupted workflow and enhanced safety.

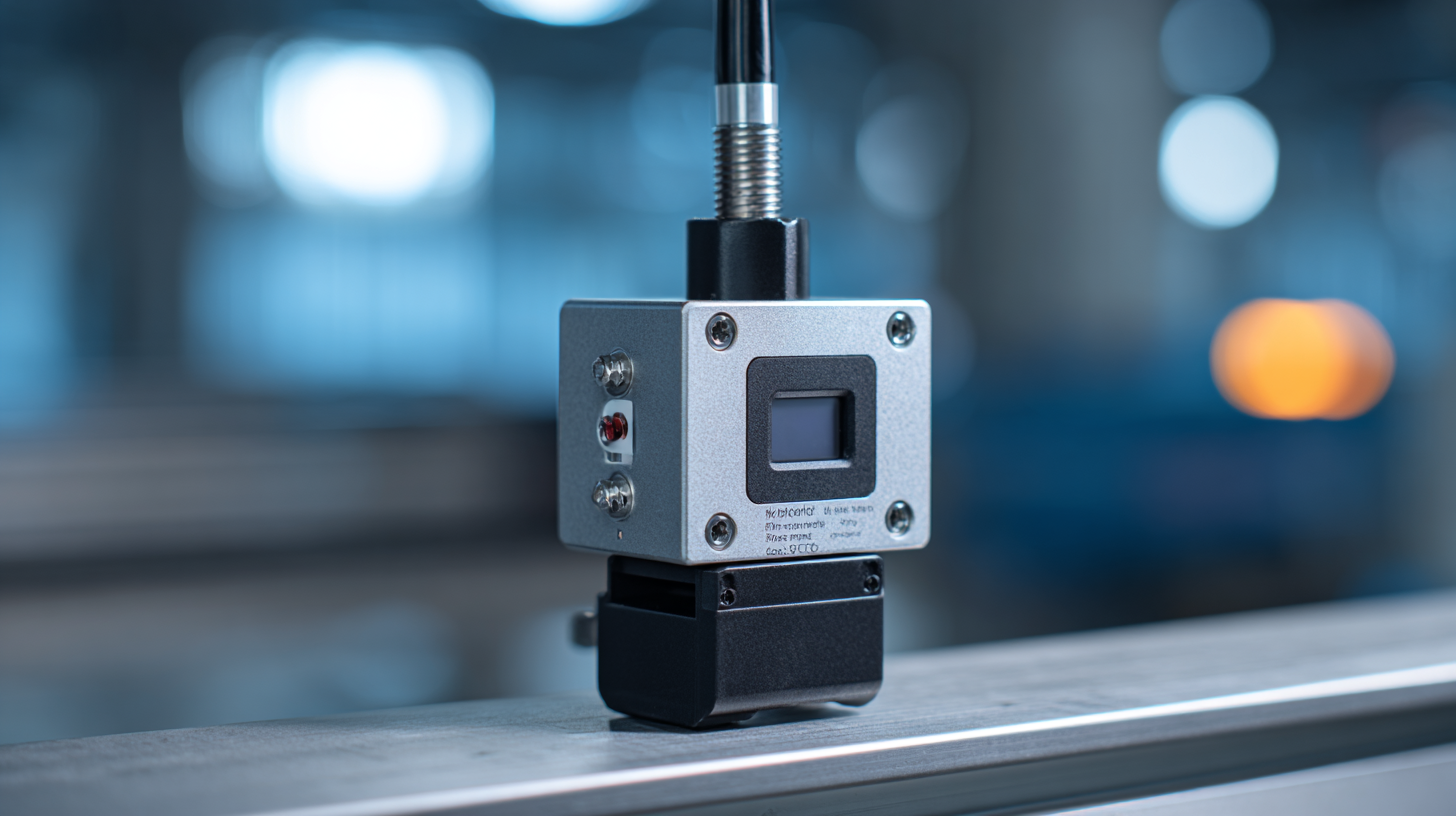

The Role of Smart Technology in Load Cell Functionality and Efficiency

As we look towards 2025, the integration of smart technology into load cell design is set to redefine the landscape of weighing solutions. Advanced sensors equipped with IoT capabilities are not just enhancing accuracy but are also paving the way for real-time data analytics. According to a recent report from MarketsandMarkets, the global load cell market is projected to reach $6.81 billion by 2025, driven partly by these innovative technologies. These smart load cells offer increased connectivity, enabling them to communicate seamlessly with other devices, which enhances operational efficiency and reduces downtime.

To optimize the performance of smart load cells, consider these tips: first, ensure proper calibration to maintain accuracy, as even the best technology can underperform if not correctly set. Secondly, invest in cloud-based systems that allow for comprehensive data tracking and analytics, further improving your load management processes. By embracing these innovations and employing best practices, businesses can fully leverage the capabilities of smart load cells.

Moreover, the future lies in adaptability, as smart load cells are being designed with machine learning algorithms that allow them to self-adapt based on environmental factors. This means less manual intervention and a greater emphasis on predictive maintenance. By prioritizing these progressive technologies, industries can expect significant advancements in both productivity and reliability.

Advancements in Load Cell Calibration Techniques for Precision Measurement

As the demand for precision measurement continues to grow in various sectors, advancements in load cell calibration techniques are increasingly important. These innovations are essential not only for enhancing accuracy in scientific and industrial applications, but also in everyday technology where precise weight measurements can impact functionality and user experience. The development of improved calibration methods aims to reduce errors, streamline the calibration process, and ensure consistency across different measuring systems.

In the realm of wearable devices, for instance, accurate load cell measurements play a crucial role in monitoring health metrics such as glucose levels. The integration of advanced calibration techniques can significantly enhance the reliability of these devices, making them indispensable for diabetes management. As we look towards 2025, the focus on refining load cell technology will likely open new avenues for applications, from high-tech sensors that measure subtle changes in weight due to physical movement to intelligent systems that monitor environmental factors in real-time. This momentum not only reflects broader trends in the Internet of Things (IoT) but also emphasizes the critical need for precise measurement solutions that seamlessly integrate into our daily lives.

Sustainability Trends in Load Cell Manufacturing and Recycling Solutions

As we look ahead to 2025, sustainability trends in load cell manufacturing are becoming increasingly crucial. The industry is witnessing a shift towards greener production processes and materials, segmenting itself to align with global sustainability goals. In this context, innovations in load cell technologies not only focus on enhancing performance but also emphasize reducing environmental impact through energy-efficient practices and sustainable sourcing of materials. This transformation resonates with broader trends across various sectors, characterized by an emphasis on eco-friendly production techniques and waste reduction.

Recycling solutions are also gaining traction, with closed-loop systems that minimize waste and promote the reuse of materials becoming more prevalent. These methodologies parallel advancements in other industries, such as the recycling of lithium-ion batteries, which is critical for achieving a circular economy. The commitment to sustainability will drive research and development in load cell technology, leading to the adoption of new materials that are easier to recycle and manufacture. Exploring these trends highlights the importance of integrating innovative practices in the load cell sector, paving the way for a more sustainable future in technology.

Exploring Sustainability Trends in Load Cell Manufacturing (2023-2025)

The Impact of IoT on Load Cell Applications Across Industries

The introduction of the Internet of Things (IoT) has begun to transform load cell applications, enabling smarter and more efficient solutions across various industries. With the ability to connect load cells to the cloud, organizations can harness real-time data analytics to monitor and optimize performance. This advancement allows for predictive maintenance, significantly reducing downtime and improving operational efficiency. Industries such as manufacturing, logistics, and healthcare can now incorporate these smart sensors into their processes, providing valuable insights that were previously unattainable.

Furthermore, the integration of IoT technology into load cell systems facilitates enhanced automation and control. For example, in the agricultural sector, farmers can utilize load cells equipped with IoT capabilities to monitor crop weights directly from their devices, allowing for timely and informed decision-making. Similarly, in retail, smart load cells can optimize inventory management by tracking stock levels in real time. As we look toward 2025, the potential for IoT in load cell applications is immense, paving the way for more innovative and efficient solutions tailored to the needs of diverse industries.