sales@loadcellsensor.com

sales@loadcellsensor.com

Understanding the Impact of 3 Axis Force Sensors on Modern Robotics and Automation

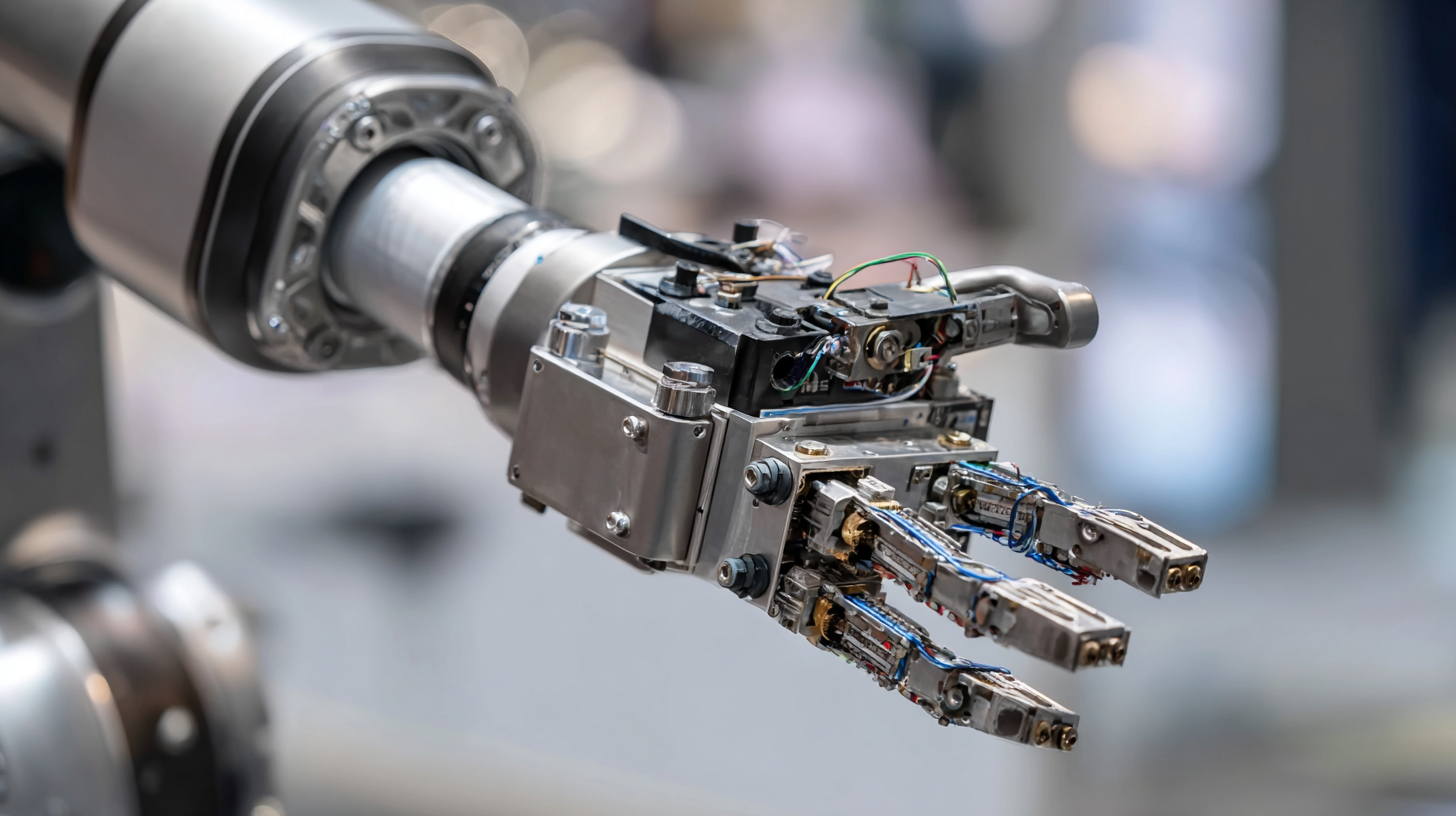

The integration of 3-Axis Force Sensors is revolutionizing the landscape of modern robotics and automation, enhancing precision and efficiency across various applications. According to a report by MarketsandMarkets, the global market for force sensors is projected to grow from $1.1 billion in 2020 to $1.8 billion by 2025, driven largely by advancements in robotics, automotive testing, and wearable technology. These sensors play a crucial role in providing real-time feedback on the forces applied to robotic joints, enabling adaptive control and enhancing the robot's ability to interact safely with their environment. With manufacturers increasingly prioritizing automation to improve productivity, the implementation of 3-Axis Force Sensors is not only imperative for maintaining quality control but also for advancing the capabilities of robotic systems in complex tasks. As industries navigate this technological shift, understanding the impact and potential of 3-Axis Force Sensors becomes essential for fostering innovation in robotics and automation solutions.

The Significance of 3 Axis Force Sensors in Enhancing Robotic Precision and Control

The integration of 3 Axis Force Sensors in modern robotics significantly enhances the precision and control capabilities of robotic systems. According to a report by Grand View Research, the global sensor market is projected to reach $250 billion by 2026, with force sensors playing a crucial role in this growth. These sensors provide real-time feedback on the forces exerted during operation, enabling robots to perform delicate tasks with an unprecedented level of accuracy. This is especially vital in industries like manufacturing and healthcare, where precision is paramount.

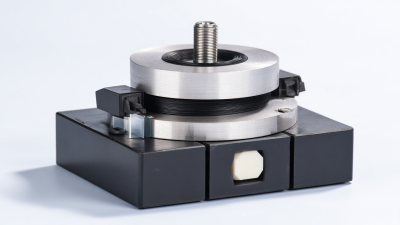

Tips: When selecting 3 Axis Force Sensors for your robotic applications, consider factors such as sensitivity, load range, and calibration stability. These aspects will ensure optimal performance and reliability in critical operations.

Moreover, the adaptability of 3 Axis Force Sensors allows them to be utilized in various robotic applications, from assembly lines to surgical robots. A study by Research and Markets highlights that 35% of automation professionals are adopting force sensors to improve operational efficiency and reduce error rates. The ability to continuously monitor and adjust forces applied by robots leads to greater safety and more effective interaction with human operators.

Tips: Implementing advanced data analytics alongside your force sensor technology can help derive deeper insights and further refine robotic performance.

Exploring the Role of 3 Axis Force Sensors in Autonomous Systems and Machine Learning

Three-axis force sensors play a pivotal role in enhancing the capabilities of autonomous systems and machine learning applications. By providing real-time data on force and torque applied in three-dimensional space, these sensors enable robots and automated systems to better interpret their environment and respond to dynamic changes. This sensory feedback allows for more precise manipulation and interaction with objects, which is crucial in tasks ranging from industrial automation to surgical robotics.

In the realm of machine learning, the integration of three-axis force sensors facilitates the collection of complex datasets that can be utilized to train algorithms for improved decision-making. These algorithms can learn from varied force interactions, enabling autonomous systems to adapt their behavior based on contextual feedback. This adaptability is essential for applications such as autonomous vehicles, where understanding physical interactions with the environment can enhance navigation and safety. As machine learning models progress, incorporating data from these sensors will lead to more intelligent and responsive autonomous systems.

Understanding the Impact of 3 Axis Force Sensors on Modern Robotics and Automation

| Parameter | Value | Unit | Application Area |

|---|---|---|---|

| Sensor Sensitivity | 0.1 | N/V | Robotics |

| Maximum Load | 50 | kg | Industrial Automation |

| Output Type | Analog | - | Robotic Grippers |

| Response Time | 5 | ms | Autonomous Systems |

| Temperature Range | -20 to 70 | °C | Outdoor Robotics |

Quantifying the Benefits of 3 Axis Force Sensors in Industrial Automation Applications

The integration of 3 Axis Force Sensors in industrial automation applications has revolutionized the way manufacturing processes are approached. These sensors provide precise measurements of force along three dimensions, allowing robots to interact more intelligently with their environment. The quantification of benefits is evident in enhanced operational efficiency, as these sensors enable real-time feedback, facilitating adaptive control systems that can optimize their tasks dynamically. Consequently, robots fitted with 3 Axis Force Sensors can adjust their actions based on the forces they experience, leading to improved accuracy in assembly tasks and better handling of varied materials.

Moreover, the implementation of these sensors significantly contributes to safety and reliability in industrial settings. By accurately measuring forces, they can prevent overload situations that might lead to equipment damage or workplace accidents. Their ability to detect unexpected changes in force can trigger immediate adjustments in robotic behavior, ensuring that processes remain within safe operational thresholds. This enhances not only the longevity of equipment but also reduces downtime due to errors, ultimately translating to greater productivity and lower operational costs in automated systems. The profound impact of 3 Axis Force Sensors on robotics is shaping a new era of smarter, safer, and more efficient manufacturing.

Impact of 3 Axis Force Sensors on Industrial Automation

This chart illustrates the benefits of 3 Axis Force Sensors in various industrial automation applications. The data represents the efficiency improvement percentage in key areas when utilizing these sensors.

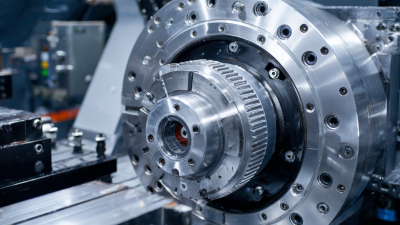

Comparative Analysis of 3 Axis Force Sensors vs. Traditional Sensors in Robotics

The advent of 3-axis force sensors has revolutionized the field of robotics, offering numerous advantages over traditional sensors. Unlike conventional technologies that might measure force in a single direction, 3-axis sensors provide comprehensive data on all three spatial dimensions. This capability allows for more accurate and nuanced feedback in robotic applications, enhancing performance in tasks such as manipulation, navigation, and interaction with dynamic environments. By capturing forces exerted during actions like grasping or moving, these sensors enable robots to adapt to varying conditions in real-time, ultimately improving their operational efficiency and effectiveness.

In a comparative analysis, while traditional sensors have served their purpose in specific applications, they often fall short in complex robotic systems where multidirectional force measurement is critical. Traditional sensors may require sophisticated algorithms to infer forces in other directions, potentially leading to inaccuracies. In contrast, 3-axis force sensors deliver immediate and precise readings, thereby simplifying the sensor integration process and reducing development time for robotic systems. As a result, industries adopting 3-axis force sensors are likely to achieve greater levels of automation and precision, driving innovation and performance improvements in robotics.

Future Trends: The Evolution of 3 Axis Force Sensors in Robotics and Automation Industries

The evolution of 3-axis force sensors is shaping the future of robotics and automation industries, responding to the increasing demand for efficient and intelligent systems. As industrial automation accelerates amid labor shortages and rising wage inflation, the integration of advanced sensory technologies has become paramount. These sensors not only enhance robots' ability to interact with their environment but also facilitate more precise and versatile operations. This evolution enables robots to perform complex tasks with increased reliability, ultimately transforming manufacturing and service sectors.

Furthermore, emerging trends indicate a significant shift towards AI-driven robotics, with companies increasingly harnessing these technologies to optimize functionality. The recent advancements in robotics, coupled with a focus on tactile feedback through force sensors, are pushing the boundaries of what automated systems can achieve. The landscape is becoming increasingly competitive, with major players investing heavily in these innovations to remain at the forefront of the industry. As we look towards 2030, the role of 3-axis force sensors in creating adaptive and smart robotic systems will be crucial for driving progress across various sectors.

Related Posts

-

Innovative Applications of Compression Force Sensors in Smart Manufacturing Technologies

-

The Ultimate Guide to Sourcing High-Quality Suppliers for Best Button Type Load Cells

-

Leading Factory in China Innovating Torque Transducers for Global Markets

-

Understanding the Key Technical Specifications of the Best Force Transducer and How to Choose the Right One

-

How to Select the Best Rotary Torque Transducer for Your Industrial Needs

-

Transforming Weighing Solutions at the 138th Canton Fair in 2025 with Pancake Load Cell Technology