sales@loadcellsensor.com

sales@loadcellsensor.com

Exploring Innovative Alternatives to the Best Tension Compression Load Cell for Global Buyers

The demand for precision measurements in various industrial sectors has led to the increasing reliance on Tension Compression Load Cells, which are pivotal in applications ranging from manufacturing to aerospace. According to a recent market report by ResearchAndMarkets, the global load cell market is projected to reach $1.5 billion by 2025, with Tension Compression Load Cells accounting for a significant share due to their versatility and high accuracy.

As industries evolve, so does the technology behind these essential devices, prompting a search for innovative alternatives that can enhance performance, reduce costs, and improve reliability. This blog delves into the top strategies for sourcing the best Tension Compression Load Cells, exploring cutting-edge developments and emerging alternatives that could serve global buyers looking to optimize their operations.

Innovative Load Cell Technologies Transforming Global Manufacturing Standards

Innovative load cell technologies are increasingly transforming global manufacturing standards, paralleling advancements seen in electrification and energy sectors. As companies strive to embrace the latest developments, load cells equipped with AI capabilities are optimizing precision and efficiency in industrial applications. For instance, the integration of IoT with load cell technology allows for real-time monitoring and adjustment, enhancing quality control and reducing waste throughout the manufacturing process.

Moreover, as the demand for sustainable practices grows, newer load cell designs are being developed to withstand harsher environments, aligning with trends in renewable energy production. The rising adoption of automation in industries is expected to propel the load cell market significantly, with projections indicating a compound annual growth rate of over 5% in the coming years. As manufacturers worldwide adopt these cutting-edge technologies, we can anticipate higher standards in operational efficiency and product quality, all crucial in an era of rapid industrial evolution.

Quality Assurance Practices for Chinese Export Manufacturers in Load Cell Production

As global demand for precision measurement solutions continues to grow, Chinese export manufacturers in the load cell production sector are prioritizing quality assurance practices to enhance their competitiveness. By implementing rigorous quality control measures, these manufacturers not only comply with international standards but also build trust with overseas buyers. This focus on quality ensures that products such as tension compression load cells meet the stringent requirements of various industries, thereby facilitating their acceptance in global markets.

Recently, innovative approaches have emerged, enabling manufacturers to overcome challenges associated with tariffs and trade barriers. For instance, some Chinese manufacturers have started establishing assembly facilities in regions like Indonesia, allowing them to maintain a presence in lucrative markets like the United States. By strategically navigating logistical and regulatory hurdles, these companies are positioning themselves to deliver high-quality load cells while remaining agile in a constantly evolving marketplace. Such adaptability is crucial for meeting the needs of international buyers seeking reliable and efficient measurement solutions.

Key Factors Influencing the Selection of Tension Compression Load Cells

When selecting tension compression load cells, several key factors come into play that can significantly impact performance. According to a recent market analysis report by Transparency Market Research, the global load cell market is projected to grow at a CAGR of 5.1% from 2021 to 2028. This growth is driven by the increasing demand for precision measurement in various industries, including manufacturing, aerospace, and healthcare. Buyers must consider load cell accuracy, which is paramount for reliable data collection; a typical high-quality tension compression load cell boasts an accuracy of ±0.05% of full scale, making them suitable for critical applications.

Another crucial factor is environmental adaptability. Many load cells are required to perform in harsh conditions – high humidity, extreme temperatures, and exposure to chemicals. The adoption of IP67-rated load cells, which offer protection against dust and temporary water immersion, is on the rise, as highlighted by a report from MarketsandMarkets. This adaptability ensures optimal performance and longevity, making them a preferred choice for global buyers. Furthermore, factors such as size, weight, and connection type should not be overlooked, as they can affect installation and integration into existing systems. These considerations play a pivotal role in selecting the most suitable load cell for specific applications, ensuring that end-users achieve both efficiency and accuracy.

Comparative Analysis of Traditional and Alternative Load Cell Solutions

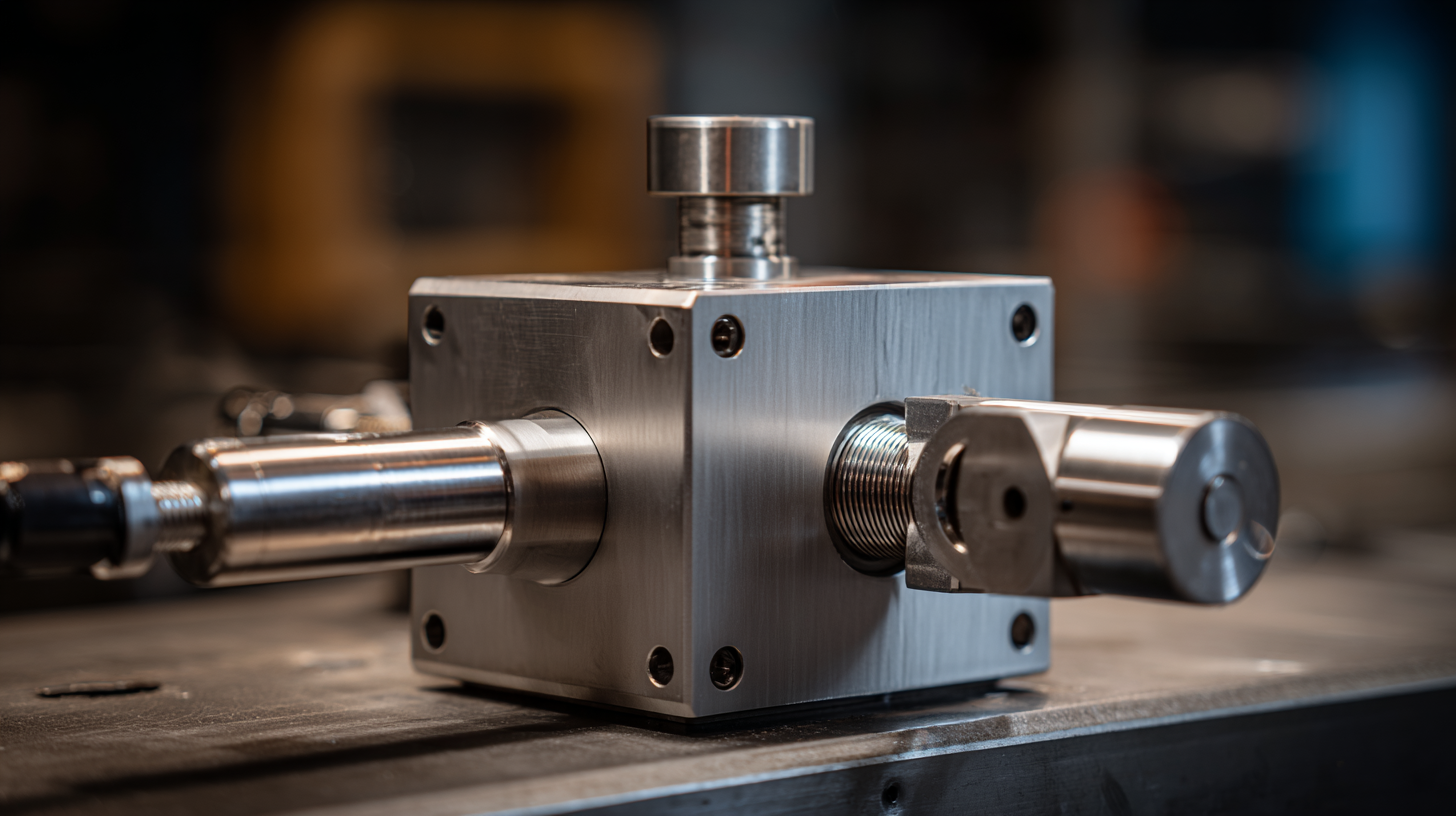

In the realm of industrial measurement, load cells are critical components that convert force into measurable electrical output. Traditional tension compression load cells have long been favored for their accuracy and reliability; however, the emergence of alternative load cell solutions is reshaping the landscape. This comparative analysis aims to delve into the strengths and weaknesses of both conventional load cells and their innovative alternatives. While traditional options including hydraulic and strain gauge load cells provide well-established performance, they often come with limitations such as sensitivity to environmental changes and complex calibration processes.

On the other hand, newer alternatives like piezoelectric and fiber optic load cells are gaining traction due to their unique advantages. Piezoelectric load cells, for instance, offer high-frequency response and are less susceptible to noise and interferences. Fiber optic load cells, meanwhile, provide remarkable durability and resistance to extreme conditions, making them ideal for challenging environments. By examining the practical implications of these technologies, global buyers can make informed decisions tailored to their specific application needs, recognizing that the choice between traditional and alternative load cells can significantly impact both the accuracy and efficiency of their measurement systems.

Exploring Innovative Alternatives to the Best Tension Compression Load Cell for Global Buyers - Comparative Analysis of Traditional and Alternative Load Cell Solutions

| Load Cell Type | Max Capacity (kg) | Accuracy (%) | Material | Price (USD) | Main Application |

|---|---|---|---|---|---|

| Strain Gauge Load Cell | 1000 | ±0.01 | Aluminum | 150 | Industrial Weighing |

| Piezoelectric Load Cell | 500 | ±0.02 | Quartz | 300 | Dynamic Force Measurement |

| Capacitive Load Cell | 750 | ±0.05 | Plastic | 200 | Laboratory Use |

| Optical Load Cell | 2000 | ±0.01 | Borosilicate Glass | 500 | Precision Engineering |

Trends Driving the Global Demand for High-Performance Load Cells

As the demand for high-performance load cells escalates, several trends are shaping the global market landscape. A significant driver is the growth of energy storage technologies, which necessitate precise measurement and control systems, such as advanced tension compression load cells. With industries focusing on sustainable energy solutions, these load cells are becoming critical for optimizing performance in energy management systems.

Additionally, the expansion of electric vehicle (EV) markets is contributing to the increased need for load cells that can handle the complexities of EV battery production. High-quality tension compression load cells are essential for ensuring safety and efficiency in the manufacturing processes, aligning well with the sustainability goals of the automotive industry.

**Tips:** When selecting load cells, buyers should prioritize those that offer high accuracy and durability. It's also beneficial to consider models that integrate seamlessly with current technology, including AI and advanced energy management systems, to enhance operational efficiency. Lastly, staying informed about market trends can provide insights into emerging technologies and applications that may impact future needs.

Exploring Innovative Alternatives to the Best Tension Compression Load Cell

This chart illustrates the global demand trends for high-performance load cells, highlighting the market for tension and compression load cells, overall market growth, and ongoing innovations in load cell technology. The data represents the demand in million units for each category, reflecting the dynamic nature of this sector.