sales@loadcellsensor.com

sales@loadcellsensor.com

How to Maximize Efficiency in Your Operations with Bending Beam Load Cells

In today's fast-paced industrial landscape, maximizing operational efficiency is a critical goal for businesses striving to enhance productivity and minimize costs. One of the most effective tools for achieving this is the Bending Beam Load Cell, a device that provides precise weight measurements and can significantly improve various processes. By integrating a Bending Beam Load Cell into your operations, you can gain real-time insights into load performance, streamline material handling, and ensure quality control across production lines.

This article will explore strategies for leveraging Bending Beam Load Cells to optimize workflow, reduce downtime, and enhance overall system reliability, ultimately empowering organizations to achieve their operational goals and enhance their bottom line.

Understanding the Basics of Bending Beam Load Cells in Operational Efficiency

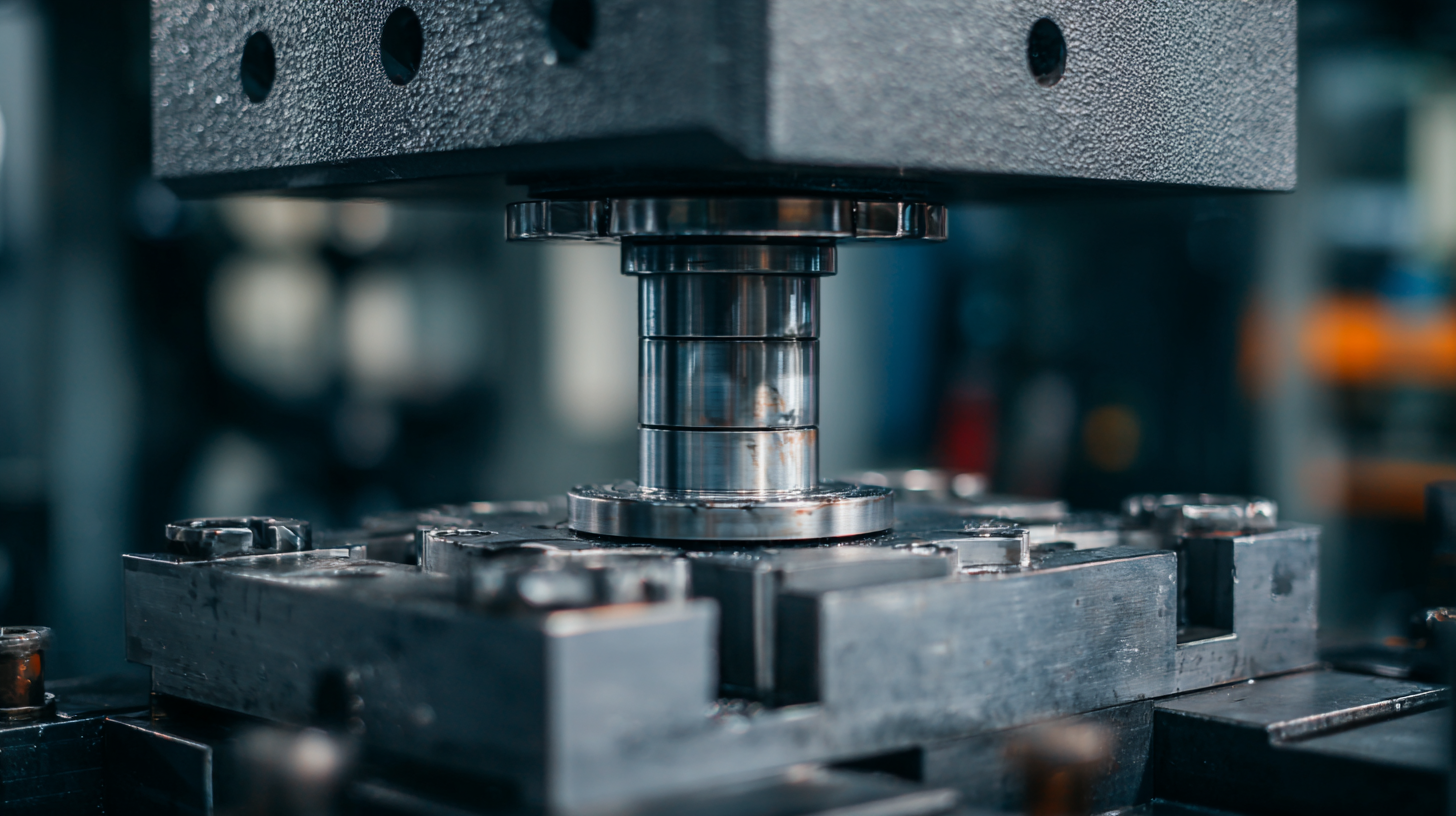

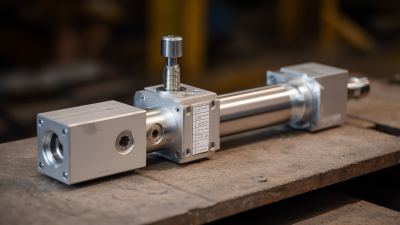

Bending beam load cells are essential components in a variety of industrial applications, primarily used for weighing and force measurement. Their design allows for precise measurement of force applied along the beam, making them ideal for various operational scenarios. Understanding their basic principles is crucial for businesses looking to enhance efficiency in their processes. These load cells convert mechanical strain into an electrical signal, offering real-time feedback that can improve decision-making and operational oversight.

By integrating bending beam load cells into your operational framework, you can streamline production processes and enhance quality control. Their compact design and accuracy ensure that they can fit into tight spaces without sacrificing performance. Moreover, they are often employed in automated systems, where continuous monitoring of weight and force can prevent overloads and equipment failure. Employing these load cells not only helps in maintaining product integrity but also optimizes the overall workflow, resulting in significant time and cost savings for enterprises aiming for operational excellence.

Identifying Key Areas to Implement Bending Beam Load Cells for Maximum Impact

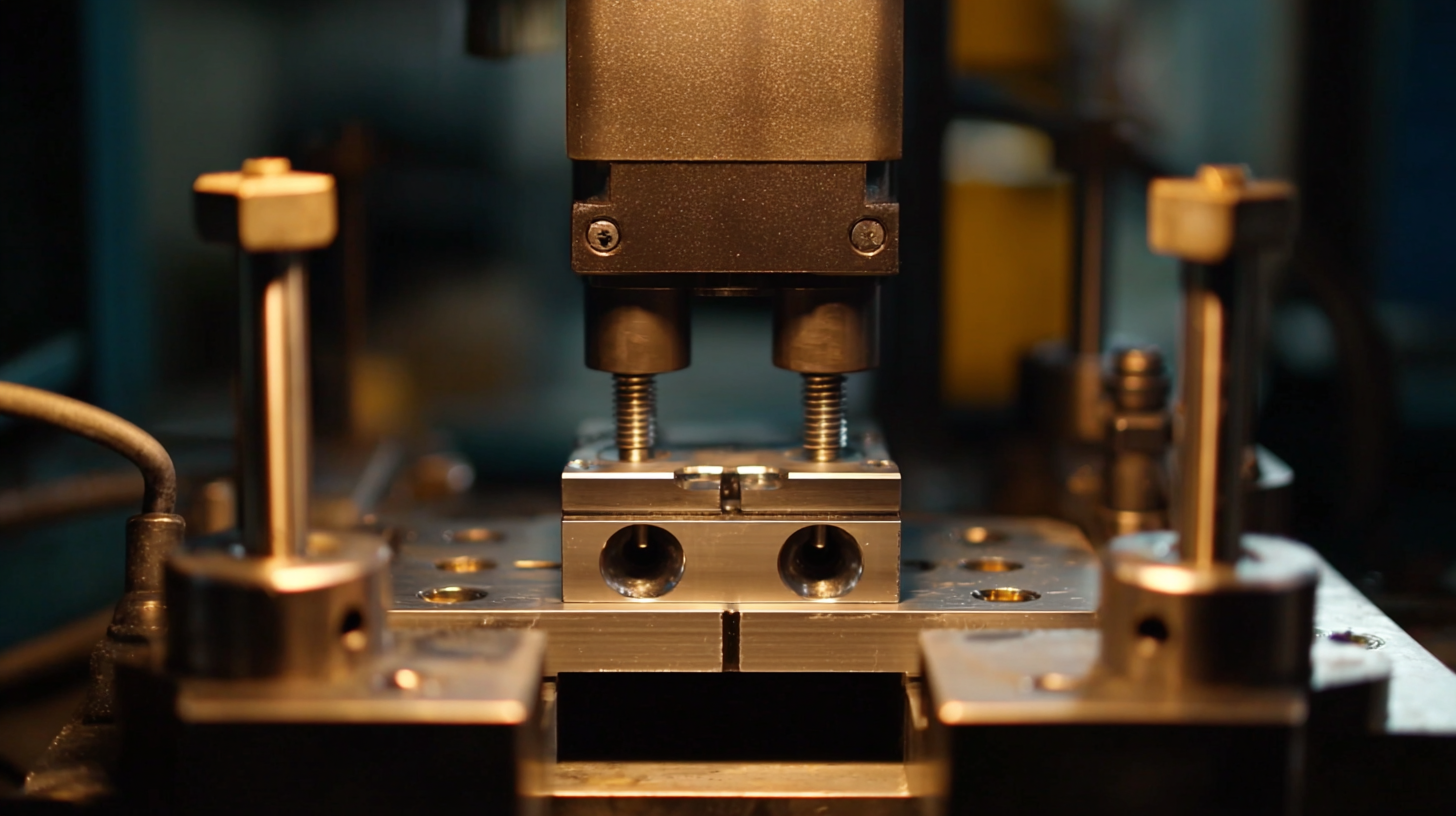

In modern manufacturing and industrial operations, identifying key areas to implement bending beam load cells can significantly enhance efficiency. These sensors are particularly beneficial in applications requiring precise weight measurement, such as in the packaging and shipping industries. According to a report by MarketsandMarkets, the load cell market is projected to grow from $3.7 billion in 2021 to $5.3 billion by 2026, reflecting an increasing reliance on technology that enhances reliability and accuracy in weight measurement.

Furthermore, bending beam load cells offer advantages in both static and dynamic load scenarios, making them ideal for conveyor systems and batching applications. A study conducted by the National Institute of Standards and Technology found that using high-precision load cells can lead to a reduction in material waste by up to 20%, contributing not only to operational efficiency but also to sustainability efforts. By strategically integrating bending beam load cells in these key operational areas, businesses can realize substantial improvements in accuracy and throughput, ultimately translating to better bottom-line results.

Integrating Bending Beam Load Cells into Your Existing Systems

Integrating bending beam load cells into your existing systems can significantly enhance operational efficiency. These load cells, which utilize a simple yet effective principle of measuring force through the bending of a beam, can be seamlessly incorporated into various applications, from manufacturing to logistics. To maximize their benefits, it is crucial to assess your current systems and identify areas where load cells can be implemented for precision weight measurements and feedback.

When integrating bending beam load cells, it's essential to ensure proper calibration and alignment with your existing equipment. This not only guarantees accurate readings but also helps maintain the integrity of your system. Consider utilizing advanced data acquisition systems that can collect and analyze load cell data in real-time, facilitating more informed decision-making. By creating a feedback loop between the load cells and your operational processes, you can better monitor performance, reduce waste, and ultimately increase productivity in your operations.

Monitoring and Analyzing Data for Continuous Improvement with Load Cells

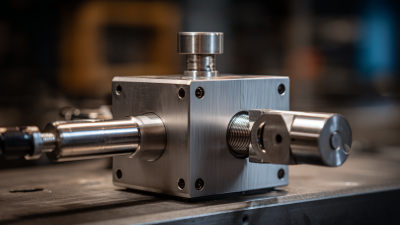

Monitoring and analyzing data are crucial for continuous improvement in any operational setting, and bending beam load cells play a pivotal role in this process. These sensors provide real-time data on weight and force, enabling businesses to monitor critical processes effectively. By integrating bending beam load cells into their systems, organizations can gather accurate measurements that facilitate detailed analysis. This allows operators to identify inefficiencies and make informed decisions based on empirical data.

Furthermore, the data collected through bending beam load cells can be analyzed over time to identify trends and patterns. This longitudinal insight enables organizations to refine their processes, reducing waste and enhancing productivity. Applying analytical techniques to load cell data can reveal opportunities for automation and optimization, leading to a more streamlined operation. Ultimately, the continuous feedback loop created by monitoring load cells empowers businesses to drive performance improvements, ensuring they remain competitive in an increasingly demanding market.

Maximizing Efficiency with Bending Beam Load Cells

This chart shows the efficiency improvement in operations after implementing bending beam load cells over a six-month period. The data reflects the percentage increase in operational efficiency observed each month.

Best Practices for Maintaining Bending Beam Load Cells for Optimal Performance

Maintaining bending beam load cells is crucial for maximizing operational efficiency in various industries. Regular calibration is one of the best practices to ensure that these load cells provide accurate measurements. According to a report by the International Society of Automation, discrepancies in weight measurement can result in substantial financial losses, estimated at 2-5% of total revenue, depending on the industry. Therefore, implementing a calibration schedule that adheres to the manufacturer’s recommendations can prevent costly mistakes and inefficiencies in production lines.

Maintaining bending beam load cells is crucial for maximizing operational efficiency in various industries. Regular calibration is one of the best practices to ensure that these load cells provide accurate measurements. According to a report by the International Society of Automation, discrepancies in weight measurement can result in substantial financial losses, estimated at 2-5% of total revenue, depending on the industry. Therefore, implementing a calibration schedule that adheres to the manufacturer’s recommendations can prevent costly mistakes and inefficiencies in production lines.

Another essential practice is to keep the environment around the load cells clean and free from contaminants. Dust, moisture, and other particulates can adversely affect the performance of load cells, leading to inaccuracies. A study published in the Journal of Manufacturing Science and Engineering indicates that implementing routine inspections and proper housing for load cells can enhance their lifespan by up to 30%. Additionally, using protective measures such as shields or enclosures can further improve their resilience against environmental factors, thereby ensuring optimal performance throughout their operational life.

Related Posts

-

5 Essential Tips for Choosing the Right Tension Compression Load Cell

-

Exploring Innovative Alternatives to the Best Tension Compression Load Cell for Global Buyers

-

Advantages of Utilizing Ring Load Cells for Precise Industrial Measurements

-

Top 10 Micro Load Cell Manufacturers from China at the 137th Canton Fair

-

15 Best Practices for Using Tension Compression Load Cell in Industry

-

The Ultimate Guide to Choosing the Best Load Cell for Your Needs