sales@loadcellsensor.com

sales@loadcellsensor.com

How to Select the Best Rotary Torque Transducer for Your Industrial Needs

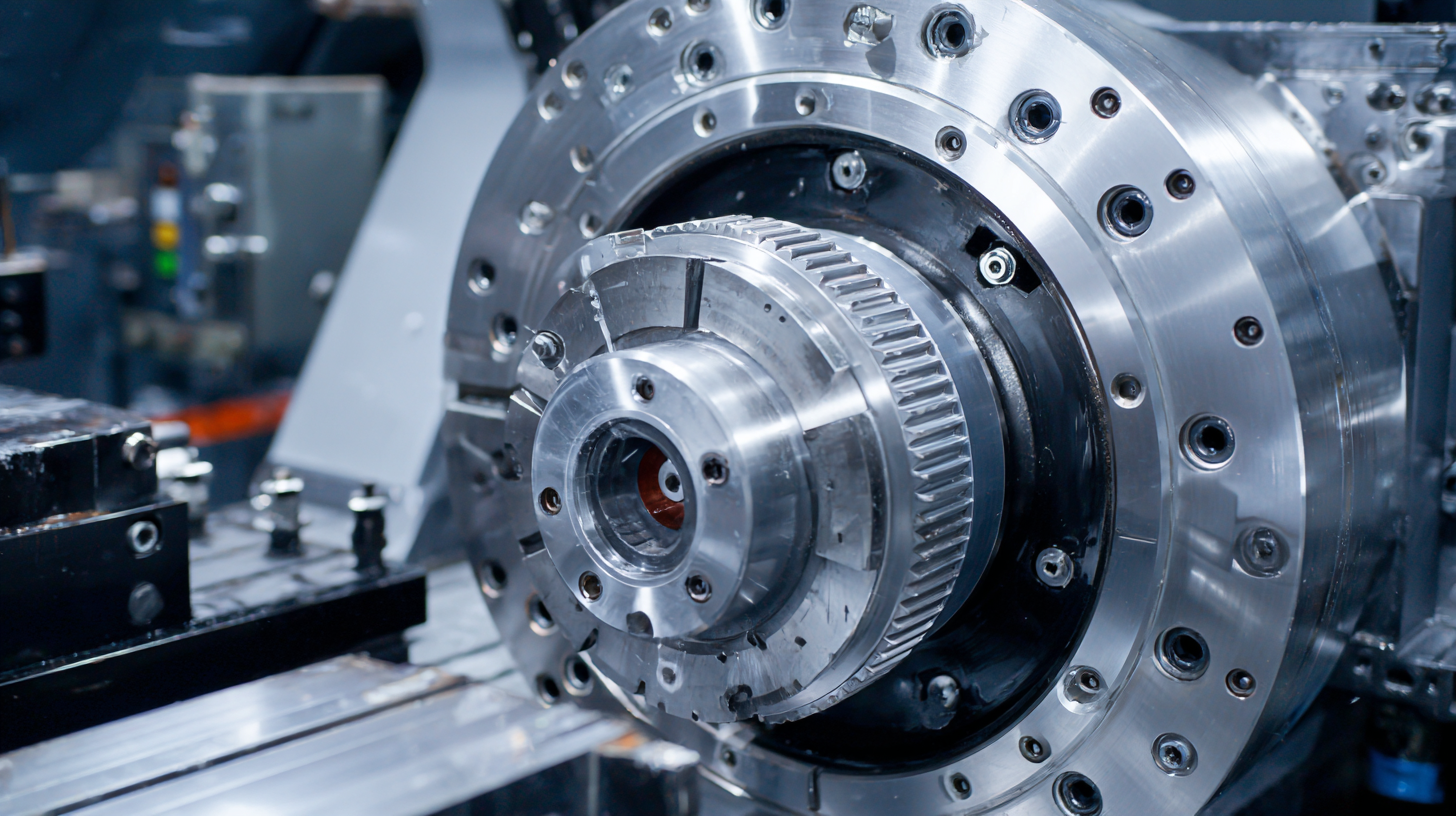

In the ever-evolving landscape of industrial machinery, the selection of the right components is crucial for efficiency and precision in operations. One such essential component is the Rotary Torque Transducer, which plays a vital role in measuring torque with high accuracy in various applications. However, businesses often face challenges when choosing the most suitable transducer for their specific needs. This article will explore common problems associated with different types of Rotary Torque Transducers, helping you understand their limitations and advantages. By delving into key considerations such as measurement range, environmental factors, and application specificity, we aim to guide you in making an informed decision that enhances productivity and ensures seamless operation in your industrial processes.

Selecting Rotary Torque Transducers: Understanding Key Specifications

When selecting a rotary torque transducer for industrial applications, understanding the key specifications is paramount. One of the most critical factors to consider is the measurement range. The chosen transducer must have a range that accommodates the maximum expected torque in your application. This ensures accuracy and longevity, as selecting a transducer with a range too narrow can lead to premature wear or even damage.

Another important specification is the accuracy level of the transducer, usually expressed as a percentage of the full-scale output. High-accuracy transducers provide more reliable data, which is essential for applications where precise torque measurements are crucial, such as in assembly lines or quality control processes. Additionally, it's vital to assess the environmental conditions in which the transducer will operate—factors like temperature, humidity, and potential exposure to dust or chemicals can affect performance. Understanding these key specifications will help you make an informed decision when choosing the right rotary torque transducer for your needs.

Evaluating Measurement Range and Resolution for Optimal Performance

When selecting a rotary torque transducer for industrial applications, evaluating the measurement range and resolution is crucial for achieving optimal performance. The measurement range defines the limits within which the transducer can accurately measure torque. It's essential to choose a transducer with a range that aligns with the expected torque levels of your machinery. For instance, if you're dealing with high-torque applications, a transducer with a broader measurement range will ensure that you capture all necessary data without exceeding the device’s limits, which can lead to inaccuracies or damage.

In addition to the range, resolution plays a significant role in the performance of torque transducers. Resolution refers to the smallest change in torque that the transducer can detect, which directly impacts the precision of your measurements. High-resolution transducers facilitate better monitoring and control of processes, enabling operators to make informed decisions based on accurate torque data. Choosing a transducer with an appropriate resolution for your application can drastically improve the reliability of your results, leading to enhanced operational efficiency and reduced risks of failure in machinery.

Importance of Environmental Conditions in Torque Transducer Selection

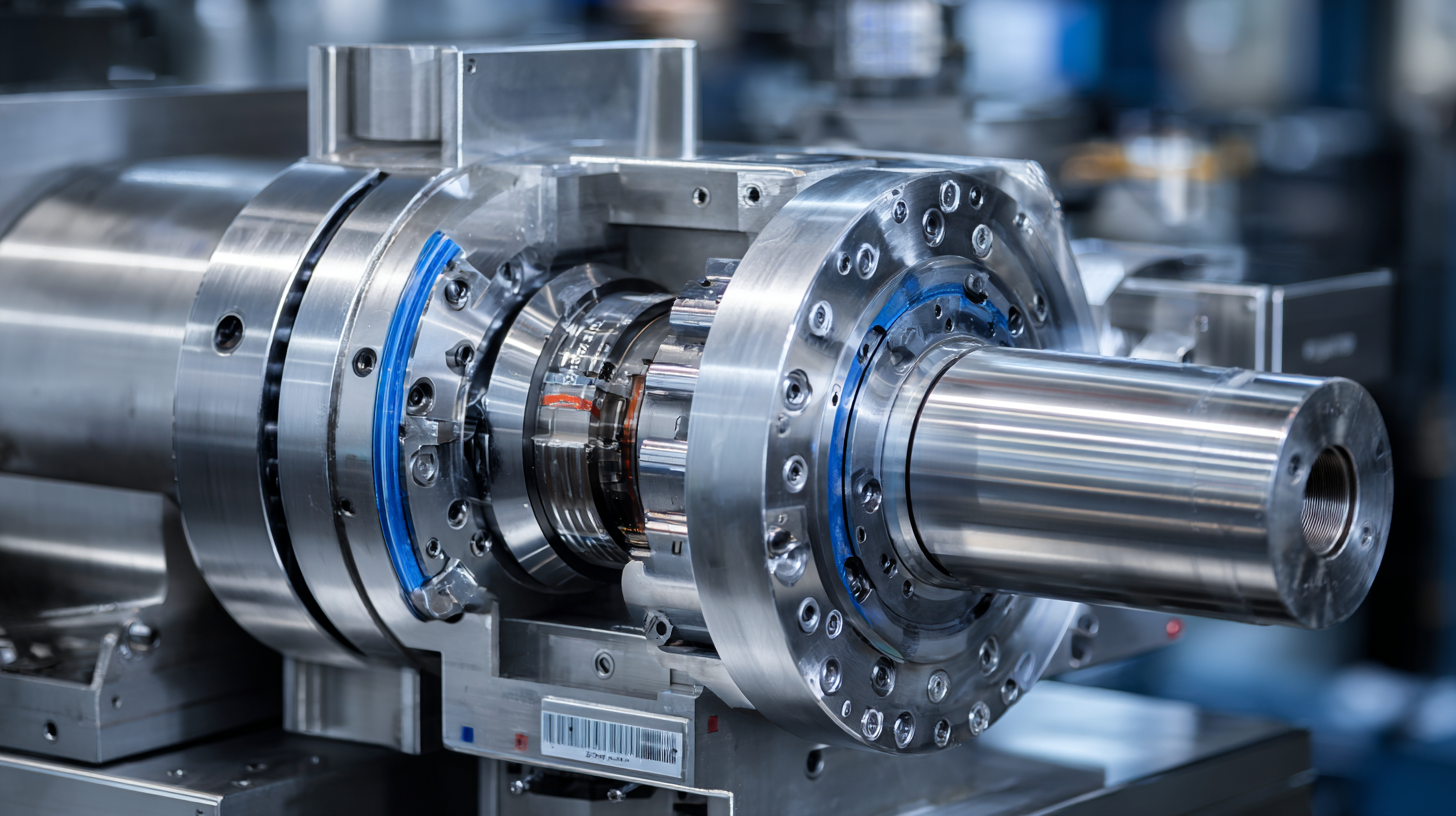

When selecting a rotary torque transducer for industrial applications, one of the most crucial factors to consider is the environmental conditions in which the device will operate. Different environments can significantly impact the performance and longevity of the transducer. For instance, high humidity levels, extreme temperatures, or exposure to dust and chemicals can lead to inaccurate measurements or even device failure. Therefore, understanding the specific environmental challenges is essential to ensure optimal functionality.

Moreover, the materials and protective features of the torque transducer play a vital role in its suitability for various conditions. Transducers designed for harsh environments typically incorporate rugged casings and seals to prevent ingress of contaminants. For applications in high-temperature areas, specialized materials that can withstand thermal stresses are imperative. Furthermore, factors such as vibration, electromagnetic interference, and potential mechanical impacts must also be taken into consideration when choosing the right transducer. By thoroughly assessing these environmental factors, companies can select a torque transducer that not only meets their operational requirements but also ensures reliability and accuracy in their measurements.

Torque Transducer Selection Based on Environmental Conditions

Comparing Analog vs Digital Output: Making the Right Choice

When selecting a rotary torque transducer for your industrial applications, understanding the differences between analog and digital output is crucial. Analog output transducers provide a continuous signal that directly correlates with the torque measurement. This type of output is often favored for its simplicity and ease of integration with existing systems. If your operation requires real-time monitoring and feedback, analog output can deliver immediate results, making it an excellent choice for applications where timing is critical.

On the other hand, digital output transducers offer enhanced precision and can provide more substantial data insights through complex algorithms. With digital output, the torque readings are processed and converted into a numeric format, allowing for easier data collection and analysis. This output is especially useful in applications requiring extensive data logging or remote monitoring capabilities. Choosing between analog and digital output should depend on your specific industrial needs, such as the complexity of the application, existing system compatibility, and the level of precision required for optimal performance.

Budget Considerations: Balancing Cost with Accuracy and Reliability

When selecting a rotary torque transducer, budget considerations play a crucial role in ensuring you achieve a balance between cost, accuracy, and reliability. According to a recent industry report by TechNavio, the global market for torque sensors is projected to grow by 5.8% annually, underscoring the increasing importance of precision in industrial applications. Companies must weigh the upfront costs against the long-term savings achieved through reduced errors and increased efficiency.

Tip: Always prioritize vendors that provide clear performance metrics and warranty information. A slightly higher initial investment in a high-quality transducer can save you from costly downtime and inaccuracies in the future.

Moreover, consider the trade-offs between different types of transducers. For instance, a piezoelectric torque sensor offers high accuracy, but it may come at a higher cost compared to strain gauge sensors. According to the latest figures from the International Society of Automation, the reliability threshold for industrial applications typically hovers around 99.5%. Choosing a reliable device that meets this benchmark ensures that your operations remain seamless without the hidden costs of repairs or recalibrations.

Tip: Evaluate total cost of ownership (TCO) instead of just the purchase price. This includes installation, maintenance, and expected lifespan, giving you a clearer picture of the true financial impact.

How to Select the Best Rotary Torque Transducer for Your Industrial Needs

| Model | Accuracy (%) | Max Torque (Nm) | Cost ($) | Reliability Rating (1-5) |

|---|---|---|---|---|

| Transducer A | ±0.5% | 100 | 850 | 4 |

| Transducer B | ±0.2% | 150 | 1200 | 5 |

| Transducer C | ±1.0% | 80 | 600 | 3 |

| Transducer D | ±0.3% | 200 | 1500 | 4 |

| Transducer E | ±0.5% | 120 | 800 | 4 |