sales@loadcellsensor.com

sales@loadcellsensor.com

Top 5 Micro Load Cells for Accurate Measurement in Industrial Applications

In the realm of industrial applications, precision and accuracy are paramount, especially when it comes to measuring load and force. Micro load cells, renowned for their ability to provide exceptional accuracy in weighings as subtle as a few grams, have become indispensable tools across various sectors, including manufacturing, automation, and consumer electronics. According to a recent industry report by MarketsandMarkets, the global load cell market is projected to reach USD 2.83 billion by 2025, with a significant portion of this growth attributed to the rising demand for high-precision measurement solutions.

Micro load cells, typically characterized by their compact design and high sensitivity, enable industries to enhance system performance and assure quality control. Whether integrated into sophisticated robotics applications or utilized in simple weighing systems, the versatility of these sensors cannot be overstated. A study conducted by Allied Market Research highlights that increasing automation in manufacturing is driving the need for more reliable load measurement solutions, further solidifying the role of micro load cells in modern industry. As we delve into the top five micro load cells available on the market today, we will explore their features, applications, and the technological advancements that make them integral to accurate measurement in industrial environments.

Top Trends in Micro Load Cell Technology for Industrial Applications

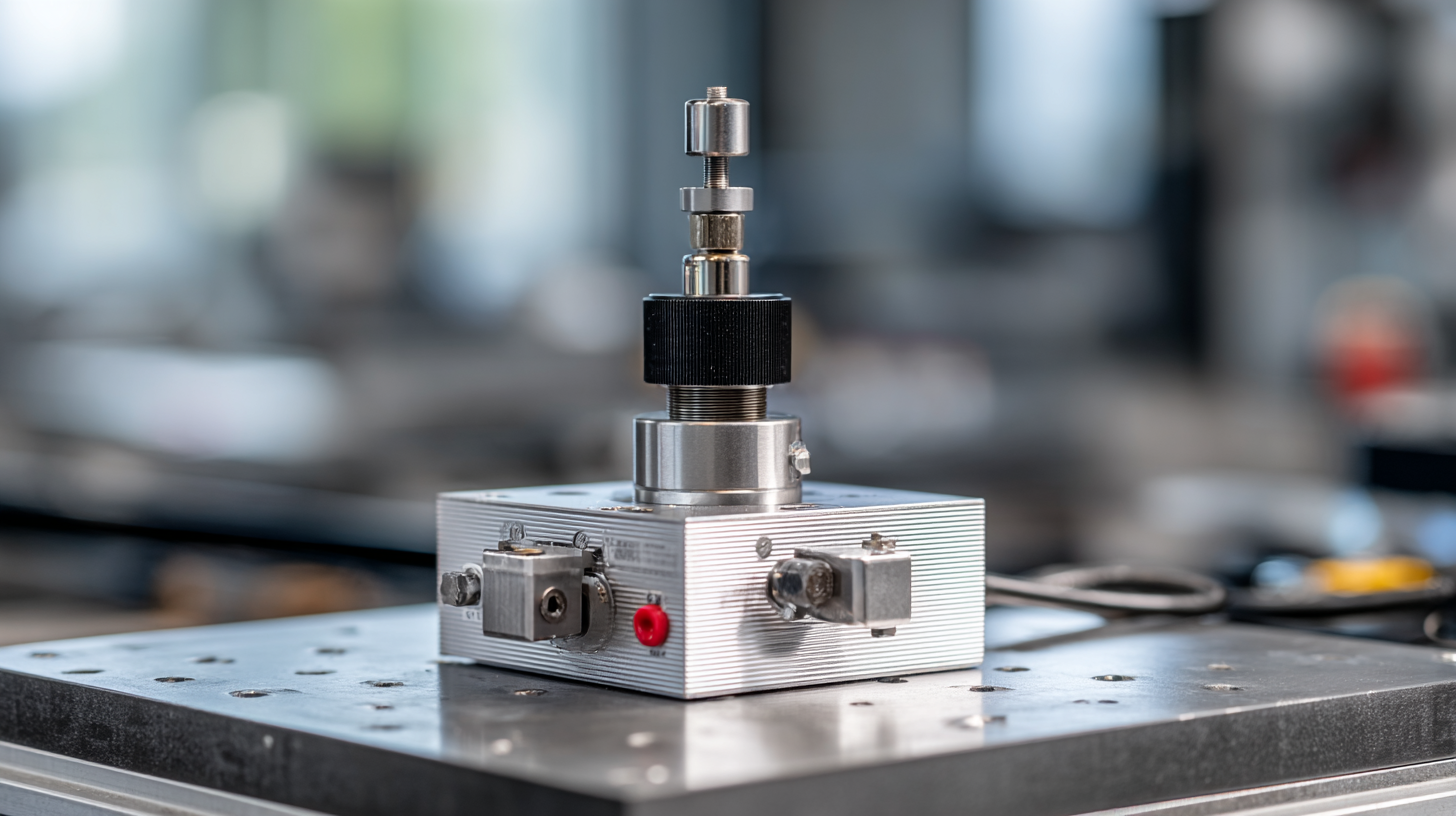

Micro load cell technology has seen significant advancements in recent years, aligning with the increasing demand for precision in industrial applications. One of the leading trends is the integration of digital interfaces, allowing for real-time data processing and seamless connectivity with industrial automation systems. This development enhances the capabilities of load cells, enabling precise monitoring and analysis of weight measurements, which is vital for quality control and operational efficiency.

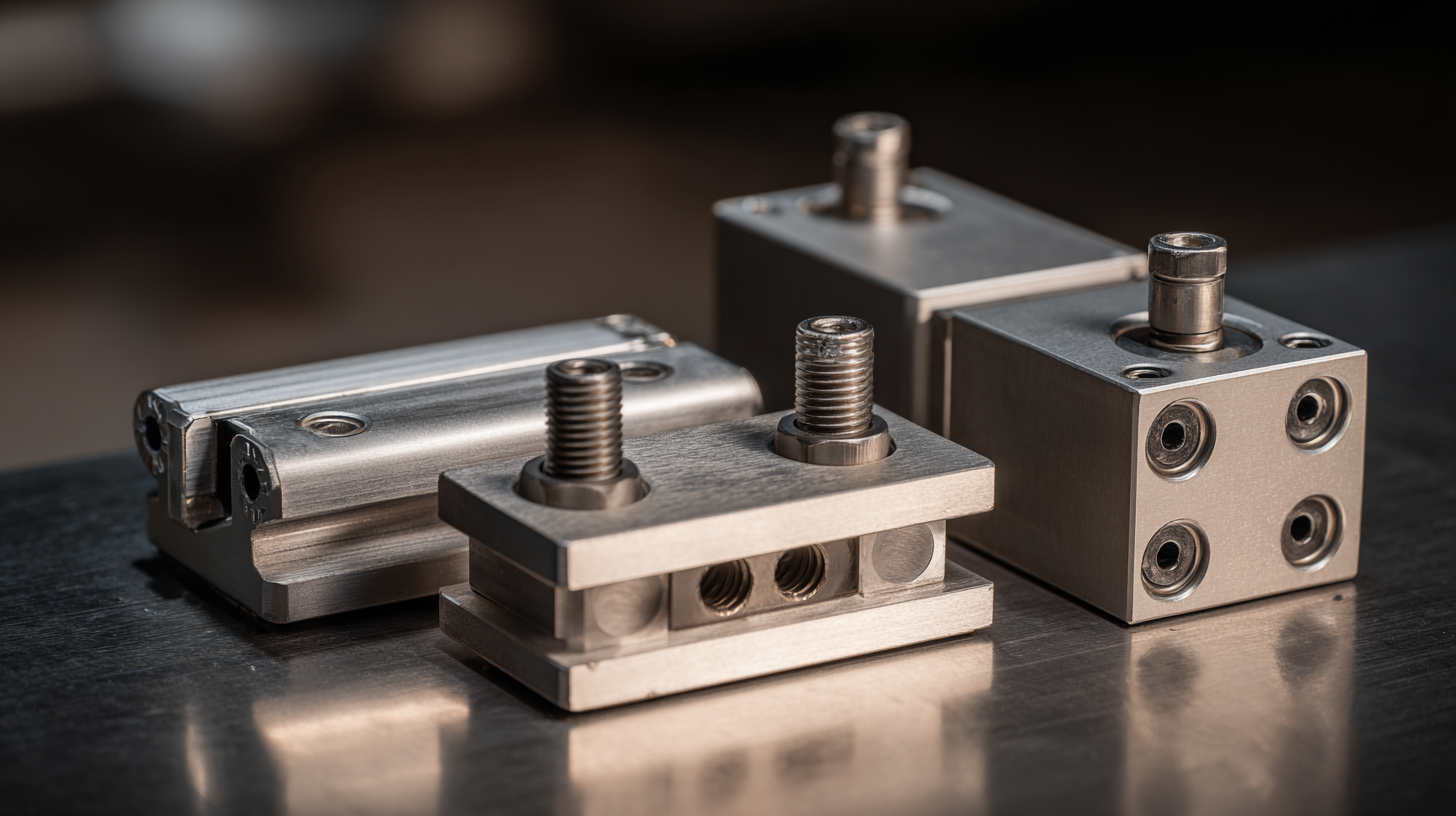

Another notable trend is the miniaturization of load cell designs. As industries strive for more compact and space-efficient solutions, manufacturers are creating smaller yet highly accurate load cells that can fit into tight spaces without compromising performance. This trend is particularly beneficial in sectors such as robotics and manufacturing, where space is often limited, but the need for accurate weight measurement remains critical. Additionally, advancements in materials science are leading to more durable and reliable load cells that can withstand harsh industrial environments, further expanding their applicability across various fields.

Key Specifications to Consider When Selecting Micro Load Cells

When selecting micro load cells for industrial applications, key specifications play a crucial role in ensuring accurate measurements. First and foremost, the load cell's sensitivity is essential; it determines how accurately the device can measure small loads. A higher sensitivity allows for finer detection, which is particularly vital in applications where precision is paramount. Additionally, the capacity of the load cell should align with the specific requirements of your project, ensuring it can handle the maximum expected load without compromising performance.

Another critical factor is temperature compensation. Load cells often face varying environmental conditions in industrial settings, and the ability to maintain accurate measurements across temperature fluctuations is vital to avoid errors. Furthermore, consider the and construction of the load cell, as these attributes will impact its durability and performance in different operational environments. For instance, corrosion-resistant materials are necessary if the load cell will be exposed to harsh substances. By carefully evaluating these specifications, users can select the most suitable micro load cells to achieve reliable results in various industrial applications.

Comparative Analysis of Top Micro Load Cells in Industrial Settings

In industrial applications, selecting the right micro load cell is crucial for ensuring accurate measurements and enhancing operational efficiency. A comparative analysis of leading micro load cell models reveals significant disparities in their performance characteristics. For instance, according to a report by the International Society of Automation (ISA), precision load cells reduce measurement errors by up to 25% compared to standard models, making them essential in high-stakes environments like aerospace and automotive manufacturing.

When examining specific products, the data shows that models such as the Honeywell ELPM and the TE Connectivity LCM Series not only boast impressive load ranges—ranging from grams to kilograms—but also feature low hysteresis and minimal drift. Reports indicate that these micro load cells provide linearity of better than 0.05% across their specified range, which is critical for applications requiring stringent accuracy standards. Furthermore, advancements in digital signal processing have enabled these load cells to deliver real-time feedback, a feature highlighted in research by the National Institute of Standards and Technology (NIST) as pivotal for automated assembly lines.

When examining specific products, the data shows that models such as the Honeywell ELPM and the TE Connectivity LCM Series not only boast impressive load ranges—ranging from grams to kilograms—but also feature low hysteresis and minimal drift. Reports indicate that these micro load cells provide linearity of better than 0.05% across their specified range, which is critical for applications requiring stringent accuracy standards. Furthermore, advancements in digital signal processing have enabled these load cells to deliver real-time feedback, a feature highlighted in research by the National Institute of Standards and Technology (NIST) as pivotal for automated assembly lines.

Ultimately, the deployment of advanced micro load cells is shaping the future of industrial measurement. Their integration into systems has been shown to increase overall productivity by 15%, as per a recent market analysis by Grand View Research. As industries continue to prioritize precision, investing in top-quality micro load cells will be crucial for maintaining competitive advantages in the market.

Applications of Micro Load Cells in Precision Engineering and Manufacturing

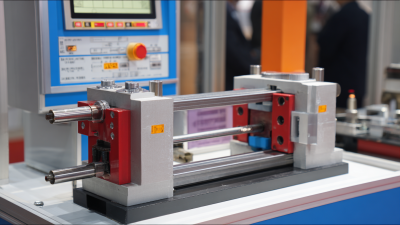

Micro load cells play a crucial role in precision engineering and manufacturing by providing accurate measurements of very small forces or loads. Their compact size and high sensitivity make them ideal for applications where traditional load cells may not fit or be suitable. Industries such as aerospace, robotics, and automotive engineering utilize micro load cells for tasks ranging from material testing to precise machinery control. By enabling precise measurements, these sensors help improve product quality and operational efficiency.

Micro load cells play a crucial role in precision engineering and manufacturing by providing accurate measurements of very small forces or loads. Their compact size and high sensitivity make them ideal for applications where traditional load cells may not fit or be suitable. Industries such as aerospace, robotics, and automotive engineering utilize micro load cells for tasks ranging from material testing to precise machinery control. By enabling precise measurements, these sensors help improve product quality and operational efficiency.

In manufacturing processes, micro load cells can monitor various parameters, ensuring that mechanisms function smoothly and components are assembled correctly. For instance, in the calibration of robotic arms, micro load cells measure the force exerted during assembly tasks, providing feedback to maintain optimal performance. Additionally, in materials testing, they help evaluate the strength and durability of materials, which is critical for ensuring safety and compliance with industry standards. The versatility and accuracy of micro load cells render them indispensable tools in modern precision engineering, driving innovation and enhancing the overall reliability of manufacturing processes.

Future Innovations and Challenges in Micro Load Cell Design and Functionality

As industries increasingly rely on precise measurements for quality control and operational efficiency, the future of micro load cell technology is poised for significant innovation. Advances in materials science and microfabrication techniques are expected to yield smaller, more sensitive load cells. These innovations could enable greater accuracy in detecting minute weight changes, which is crucial in sectors such as pharmaceuticals, food production, and aerospace. By integrating smart technologies, future micro load cells may offer real-time data analytics, enhancing their functionality and allowing for predictive maintenance to avoid costly downtimes.

However, the integration of advanced features is not without challenges. The miniaturization of load cells can compromise their durability and reliability in harsh industrial environments, leading to potential failures that can disrupt operations. Moreover, as demand for wireless and IoT-enabled devices rises, addressing issues of power efficiency and signal stability becomes paramount. Research and development efforts will need to focus on overcoming these obstacles to ensure that micro load cells can meet the evolving needs of various industries while maintaining stringent accuracy and performance standards.

Related Posts

-

Ultimate Checklist for Choosing the Best Compression Type Load Cell for Your Business Needs

-

Common Issues Faced When Using Best Small Load Cells

-

Unlocking Industry Potential with Strain Gauge Load Cells at the 2025 China Import and Export Fair

-

7 Unique Benefits of Compression Type Load Cells for Modern Industries

-

Global Sourcing Revolution: How China's Best Thin Load Cells Set the Standard for Quality and Reliability

-

The Ultimate Guide to Choosing the Best Load Cell for Your Needs