sales@loadcellsensor.com

sales@loadcellsensor.com

What is a Torque Meter for Motor and How Does It Work?

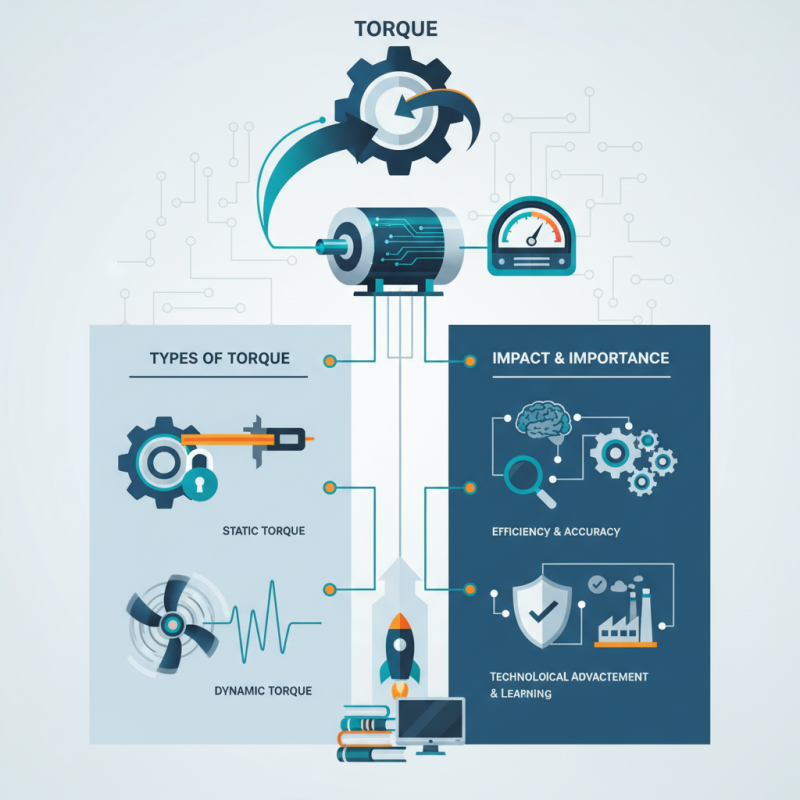

In the world of motors and machinery, measuring torque is vital. A Torque Meter For Motor is an essential tool in this field. It precisely quantifies the torque produced by a motor, ensuring optimal performance and efficiency. According to Dr. Emily Thompson, an expert in mechanical engineering, “Understanding torque is key to maximizing motor efficiency.”

These devices come in various types. Some measure static torque, while others assess dynamic torque during operation. Each type serves specific needs. For instance, a portable torque meter allows for easy field measurements. However, not all Torque Meters are created equal. Some can struggle with accuracy under extreme conditions, leading users to question their reliability.

Investing in a quality Torque Meter For Motor is crucial. It can significantly impact productivity and safety. Many engineers fear they may overlook vital details during their measurements. This can create challenges, as accurate readings play a significant role in motor performance. Understanding these tools can elevate operational standards and lead to advancements in technology. There remains a need for continuous learning and adaptation in this ever-evolving field.

What is a Torque Meter and Its Purpose in Motor Applications?

Torque meters play a crucial role in motor applications. These devices measure the torque generated by a motor during operation. Understanding torque helps engineers optimize performance and efficiency. A torque meter can assist in assessing the load a motor can handle. This is vital for ensuring that motors are not overworked or underutilized.

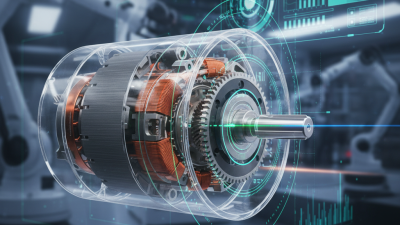

In practice, a torque meter typically connects to the motor's shaft. It uses strain gauges to monitor force and convert it into an electrical signal. This signal is then displayed as torque values. This process may seem straightforward, yet calibration is critical. Accurate readings depend on how well the device is tuned. Mistakes in this step can lead to erroneous data. Moreover, environments often complicate measurements. Variations in temperature and vibration can affect results.

While understanding the measurements is essential, interpreting them requires experience. An inexperienced operator may misread data. This can lead to mechanical failures or inefficient system performance. Therefore, proper training is necessary when working with a torque meter. Continuous learning and adaptation are key in this field. This ensures that the motor operates within its designed parameters, ultimately enhancing reliability and longevity.

The Basic Principles of Torque Measurement in Motors

Torque measurement in motors is crucial for assessing performance. A torque meter, or torque transducer, gauges the torque output of a motor in real time. This data provides insight into the motor's efficiency and power delivery. Understanding the mechanical principles behind these measurements is essential for industries reliant on electric motors.

The fundamental principle relies on the relationship between torque, power, and speed. Torque meters utilize strain gauges that detect deformations in the motor shaft. According to industry reports, accurate torque measurement can improve energy efficiency by up to 15%. Many plants, however, overlook regular calibration of these devices. This oversight can lead to inflated energy costs and reduced operational efficiency.

Industry studies indicate that 30% of motor failures are linked to improper torque settings. Thus, employing a torque meter is not just beneficial; it's often vital. However, challenges remain. Some torque meters can be expensive, and not all facilities invest in high-quality devices. This results in compromised data accuracy, affecting overall performance. Investing in reliable torque measurement technology is critical for optimizing motor function.

Components and Design of a Torque Meter Device

A torque meter is a crucial device used in various applications, especially in motors. The design of a torque meter typically involves several key components. These components include a sensor, a display unit, and the necessary interfaces for data output. The sensor could be based on strain gauges or other technologies to measure the torque applied to a shaft or motor.

The arrangement of these components significantly influences the device's effectiveness. The sensor captures real-time torque values. This data is then processed and displayed, providing insights to the user. However, the accuracy of readings can sometimes be an issue. Calibration might be required periodically to maintain precision. Some sensors may struggle with extreme conditions, leading to potential inaccuracies.

Another important aspect is the user interface. It should be intuitive yet detailed enough to provide essential information. Yet, if the display is too complex, users may find it challenging to interpret results. A balance is necessary for effective monitoring. Continuous improvement in design can help address these shortcomings and enhance overall functionality.

How Torque Meters are Calibrated for Accurate Readings

Calibrating a torque meter is essential for precise measurements. This process ensures that the device provides accurate readings of torque applied to motors. Calibration starts with a reference standard. This standard is usually a known value, like a specific torque level. Using this, the meter's readings are adjusted to match.

During calibration, various factors can introduce errors. Environmental conditions might affect the readings. Humidity or temperature changes can lead to discrepancies. Regular checks help identify these issues. A well-calibrated torque meter can significantly impact quality assurance in production.

It's important to regularly recalibrate these devices. Relying on old data can be misleading. The calibration process needs meticulous attention. Even slight misalignments can produce incorrect results. Regular maintenance and checks are crucial for optimal performance.

Applications of Torque Meters in Engineering and Industry

Torque meters play a vital role in engineering and industrial applications. They measure the torque output of motors and machinery. This information helps in optimizing performance and ensuring safety. Accurate torque measurement is essential in sectors like automotive, aerospace, and manufacturing. For instance, in automotive testing, engineers assess engine output to enhance fuel efficiency.

In manufacturing environments, torque meters ensure assembly components tighten correctly. Over-tightening can cause failures, while under-tightening may lead to component loosening. Monitoring torque during assembly processes improves quality control. In aerospace, torque measurement is crucial for safety. Even slight discrepancies can have severe consequences. Proper torque applications ensure components can withstand extreme conditions.

However, using torque meters is not without challenges. Calibration is necessary to maintain accuracy. Regular maintenance is vital to avoid erroneous readings. Not all operators are trained to use them effectively. Misunderstanding torque specifications can lead to critical errors. Reflections on these aspects can improve practices in various industries.

Torque Meter Applications in Engineering and Industry

Related Posts

-

Understanding Motor Torque Sensors: Key Benefits and Applications Explained

-

Ultimate Guide to Comparing the Top Weight Transducers for Global Buyers

-

Understanding the Key Technical Specifications of the Best Force Transducer and How to Choose the Right One

-

2025 Trends: How to Choose the Best 5kg Load Cell for Global Sourcing Success

-

Navigating the Best Force Sensor Market How to Identify Top Manufacturers with Key Comparisons

-

Precision Engineering: Chinese Manufacturing Innovating Global Torque Transducer Solutions