sales@loadcellsensor.com

sales@loadcellsensor.com

Why Understanding Compression Force Sensors Is Crucial for Modern Industries

In today's rapidly evolving industrial landscape, the importance of precise measurement and control cannot be overstated. Compression Force Sensors play a pivotal role in ensuring operational efficiency and safety across various sectors. According to a market research report by MarketsandMarkets, the global force sensor market is projected to grow from $2.1 billion in 2021 to $3.1 billion by 2026, highlighting a significant upward trend. As industries increasingly embrace automation and data-driven decision-making, the adoption of Compression Force Sensors is expected to rise, driven by their ability to provide accurate real-time data. This technology not only enhances product quality and consistency but also reduces material waste, underscoring its value in manufacturing, healthcare, and automotive applications. Understanding Compression Force Sensors is therefore crucial for organizations aiming to stay competitive and meet the demands of modern markets.

Importance of Compression Force Sensors in Industrial Applications

Compression force sensors play a vital role in various industrial applications, from manufacturing to quality control. According to a report by MarketsandMarkets, the global market for force sensors is expected to reach $2.2 billion by 2025, growing at a CAGR of 7.8%. This growth is driven by the increasing demand for precision monitoring and automation in industries such as automotive, aerospace, and medical devices. Compression force sensors provide critical data that enables manufacturers to ensure product integrity, monitor load limits, and optimize operational efficiency.

Compression force sensors play a vital role in various industrial applications, from manufacturing to quality control. According to a report by MarketsandMarkets, the global market for force sensors is expected to reach $2.2 billion by 2025, growing at a CAGR of 7.8%. This growth is driven by the increasing demand for precision monitoring and automation in industries such as automotive, aerospace, and medical devices. Compression force sensors provide critical data that enables manufacturers to ensure product integrity, monitor load limits, and optimize operational efficiency.

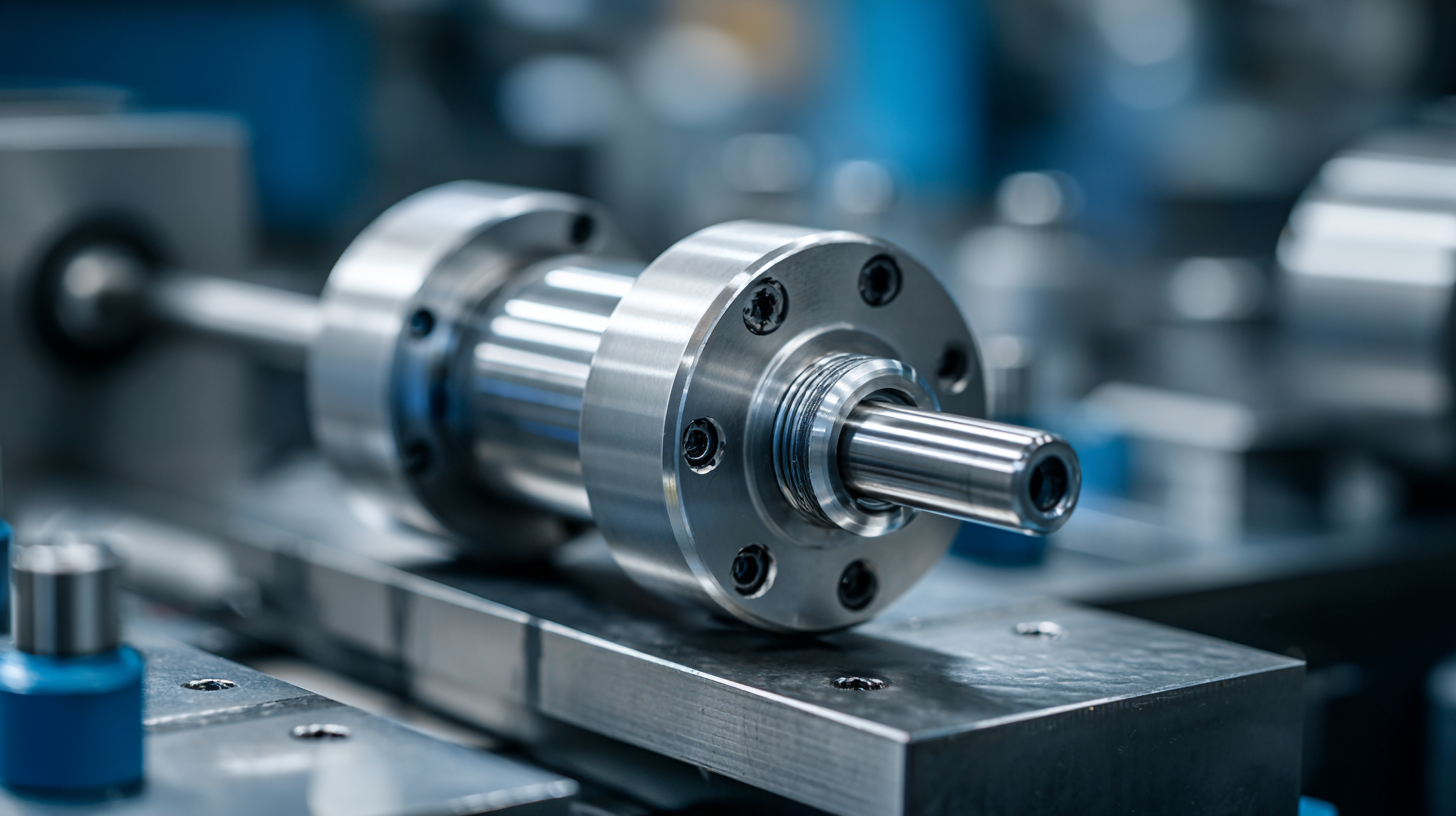

In the automotive industry, for instance, compression force sensors are extensively used for measuring bolt tightness and ensuring that components are securely assembled. A study from the International Journal of Advanced Manufacturing Technology revealed that using accurate compression sensors reduced assembly errors by up to 30%, leading to lower warranty claims and improved safety outcomes. This highlights their importance not just in manufacturing processes, but also in maintaining compliance with stringent industry standards. The integration of compression force sensors is thus essential for achieving higher reliability and quality in modern industrial operations.

Role of Compression Force Sensors in Enhancing Product Quality and Safety

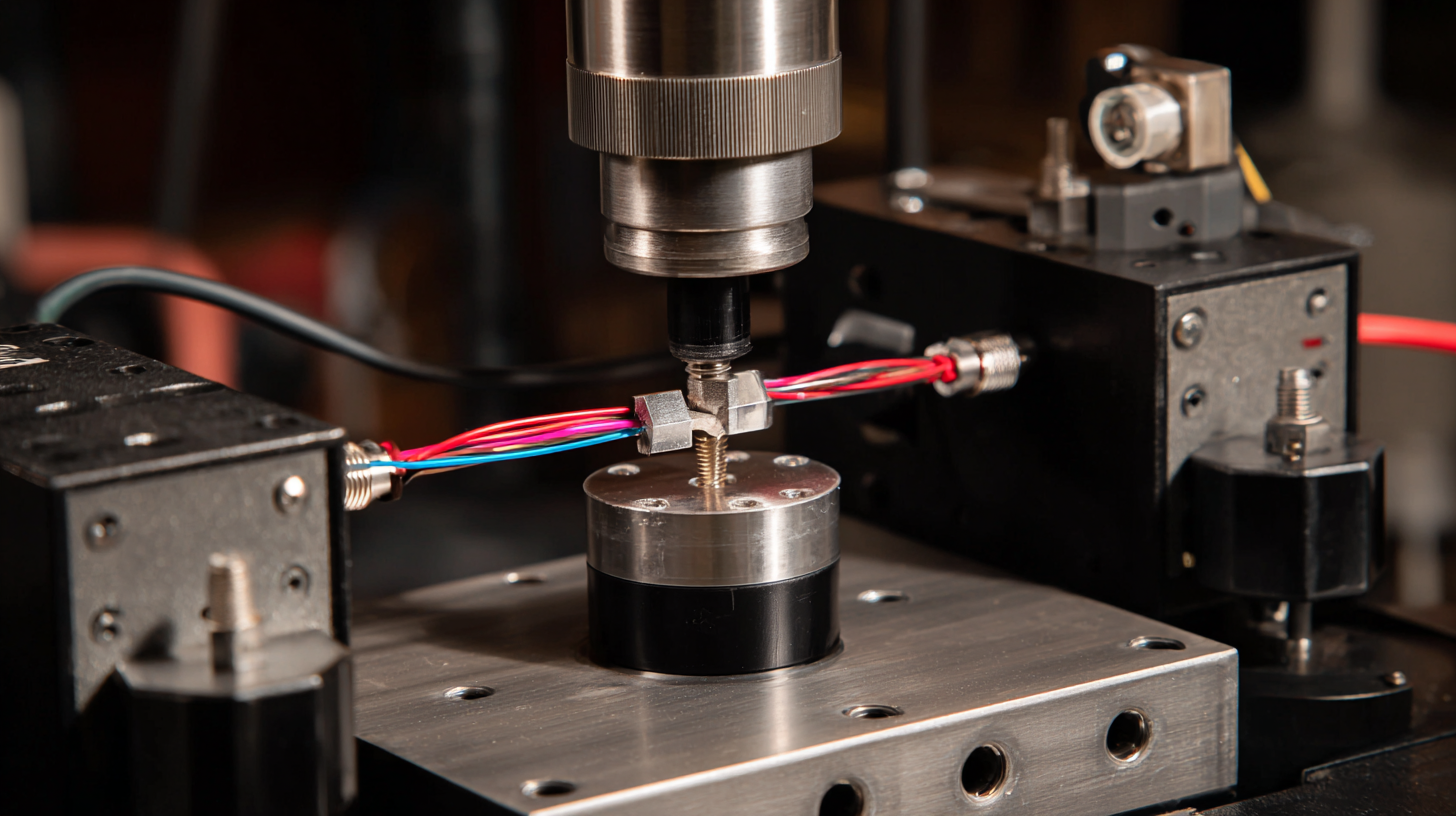

The role of compression force sensors in modern industries is pivotal for enhancing product quality and safety. These sensors provide critical data during manufacturing processes, enabling precise control over the application of force in various operations, from tablet production in pharmaceuticals to the construction of reinforced concrete structures. For instance, the real-time release testing of tablets underscores how careful monitoring of compression parameters can ensure uniformity and efficacy, directly impacting patient compliance and therapeutic outcomes.

Moreover, advancements in smart applications utilizing IoT and AI technology are reshaping sectors like agriculture and sustainable manufacturing. By integrating compression force sensors into these smart systems, industries can optimize production processes, reduce waste, ensure safety, and maintain high standards of quality. In the context of sustainable building materials, employing such sensors can enhance the performance and durability of materials while minimizing environmental impacts. This cross-disciplinary approach illustrates the necessity of understanding and implementing compression force sensors to meet both quality and safety criteria in contemporary production environments.

Impact of Compression Force Sensors on Automation and Efficiency

Understanding compression force sensors is essential for modern industries keen on enhancing automation and operational efficiency. These sensors provide precise measurements of the force exerted during the compression of materials or components, making them invaluable in various applications, from manufacturing to robotics. With reliable force measurement, industries can ensure optimal performance, reduce waste, and increase the accuracy of assembly processes.

To maximize the benefits of compression force sensors, consider these tips: First, regularly calibrate the sensors to maintain accuracy, as environmental factors can affect their performance over time. Second, integrate these sensors with automated systems to enable real-time monitoring and data analysis, facilitating immediate adjustments and minimizing downtime. Lastly, select sensors with suitable specifications for your specific application, as various types, like piezoelectric or resistive sensors, may offer distinct advantages depending on the industry need.

Automation thrives on the reliable data provided by compression force sensors. By leveraging these advanced technologies, industries can streamline processes, reduce manual intervention, and enhance productivity, paving the way for smarter and more efficient operations in today's competitive landscape.

Why Understanding Compression Force Sensors Is Crucial for Modern Industries

| Industry | Application | Compression Force Sensor Type | Impact on Efficiency | Typical Measurement Range |

|---|---|---|---|---|

| Manufacturing | Quality Control | Piezoelectric Sensors | Increases defect detection rates by 30% | 0-1000 N |

| Automotive | Component Testing | Strain Gauge Sensors | Reduces test cycle time by 25% | 0-5000 N |

| Aerospace | Load Monitoring | Capacitive Sensors | Enhances safety by accurate load tracking | 0-20000 N |

| Construction | Structural Integrity Testing | Load Cells | Improves maintenance scheduling by 40% | 0-10000 N |

| Electronics | Product Testing | Thin Film Sensors | Decreases time to market by 15% | 0-500 N |

Challenges in Implementing Compression Force Sensor Technology

Understanding the challenges in implementing compression force sensor technology is pivotal for modern industries, particularly in sectors like pharmaceuticals and textiles. As reported in recent studies, the integration of machine learning algorithms for real-time release testing has revealed the necessity of precise compression force measurements. Increased accuracy in these measurements enables manufacturers to predict in vitro dissolution profiles more effectively, which is critical for ensuring product quality and compliance. According to the FDA, over 50% of pharmaceutical recalls are related to quality control issues, stressing the importance of robust testing technologies.

In the textile industry, the push for sustainable practices has led to the adoption of flexible force sensors that not only monitor fabric performance but also evaluate the durability of materials under various conditions. Challenges here include the need for sensors that can withstand extreme environments while providing reliable data. A report from the International Textile Manufacturers Federation highlights that nearly 70% of textile companies face significant hurdles in integrating advanced sensor technologies due to their high costs and the complexity of the underlying systems. Thus, overcoming these obstacles is crucial for fostering innovation and sustainability across industries.

Challenges in Implementing Compression Force Sensor Technology

Future Trends and Innovations in Compression Force Sensor Development

The development of compression force sensors is witnessing transformative trends, propelled by advancements in technology and increasing demand across various sectors. According to a report by MarketsandMarkets, the global force sensor market is expected to reach $2.80 billion by 2025, growing at a CAGR of 7.2% from 2020. This growth is largely attributed to the rising demand for automation and smart manufacturing solutions, where accurate measurement of force is vital for performance monitoring and quality control.

One notable trend is the integration of IoT capabilities into compression force sensors, allowing real-time data collection and analysis. This connectivity not only enhances operational efficiency but also provides actionable insights for predictive maintenance. Furthermore, advancements in materials science are leading to the development of more sensitive and robust sensors, capable of measuring a wider range of forces with greater precision. As industries continue to embrace digital transformation, the evolution of compression force sensors will play a critical role in enhancing productivity and safety in manufacturing, healthcare, and many other applications.

Related Posts

-

10 Compelling Reasons to Choose Force Sensors for Your Next Project

-

Explore Cutting-Edge Weight Sensors at the Record-Breaking 137th Canton Fair!

-

Navigating Industry Standards for Best Weight Transducer and Its Challenges

-

5 Key Advantages of Choosing the Best Force Transducer for Your Applications

-

Ultimate Guide to Comparing the Top Weight Transducers for Global Buyers

-

Understanding the Key Technical Specifications of the Best Force Transducer and How to Choose the Right One