sales@loadcellsensor.com

sales@loadcellsensor.com

Pancake Load Cell Tips for Accurate Weighing Applications?

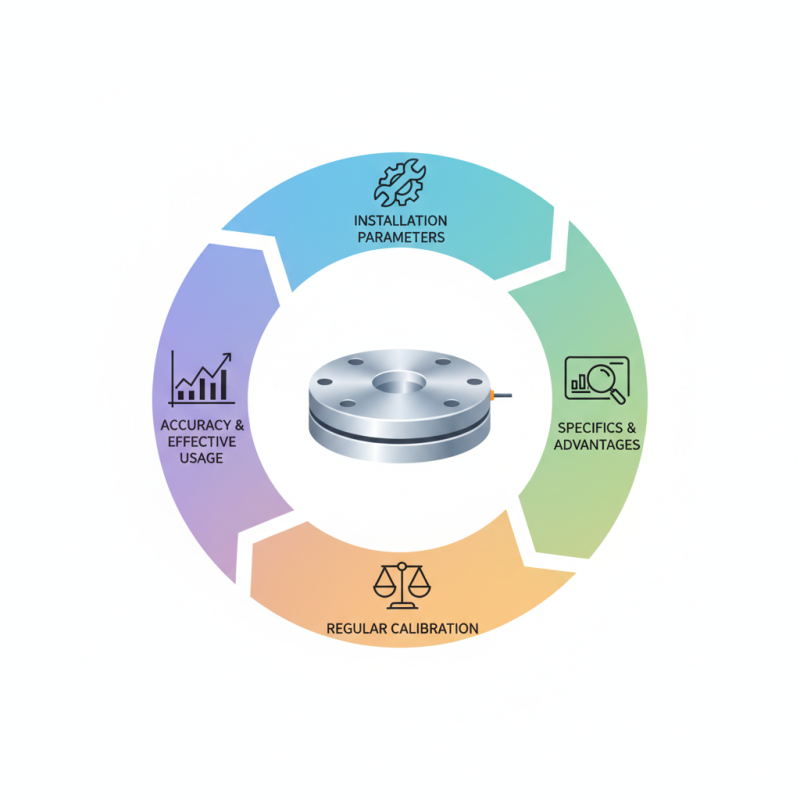

In the world of industrial weighing, precision is paramount. Pancake Load Cells play a crucial role in achieving accurate measurements. Industry expert Dr. Jane Smith once stated, "A properly calibrated pancake load cell can make a significant difference in weight data accuracy." This highlights the importance of correct usage in weighing applications.

Pancake Load Cells come in various sizes and configurations. Their flat design allows for easy integration into weighing systems. However, many users overlook critical installation parameters. This can lead to errors in weight readings.

Understanding the specifics of pancake load cells is essential. They offer several advantages, like high stiffness and low profile. Yet, improper setup can result in inconsistent measurements. Regular calibration is vital to maintain accuracy. Pay attention to these factors to fully leverage pancake load cells effectively.

Pancake Load Cell Overview: Key Features and Functionality

Pancake load cells are critical for precision in weighing applications. They offer a flat design, making them ideal for limited spaces. This type of load cell excels in measuring static and dynamic loads accurately. They are often used in industrial settings, but their versatility extends to various scales and platforms.

One key feature is their high accuracy. Many pancake load cells can detect small weight changes. This sensitivity is important for applications requiring detailed measurements. Their robust construction enhances durability, but this can lead to overestimating their limits. Users must be cautious and not assume they can handle all extremes without testing.

Another aspect is the installation process. Although pancake load cells are user-friendly, improper installation can lead to inaccuracies. The alignment is crucial; any misalignment results in erroneous readings. Regular calibration can help maintain accuracy, but it's often overlooked. Users should reflect on their processes and regularly check their equipment to ensure consistent performance.

Pancake Load Cell Tips for Accurate Weighing Applications

| Feature | Description | Application | Load Capacity (lbs) |

|---|---|---|---|

| High Precision | Provides precise weight measurements with minimal error. | Industrial weighing scales, laboratory measurements. | 0-10,000 |

| Compact Design | Small form factor suitable for tight spaces. | Portable weighing applications, force measurement systems. | 0-5,000 |

| Versatile Applications | Can be used in various weighing setups and environments. | Shipping, production lines, scientific research. | 0-15,000 |

| Durability | Built to withstand harsh conditions and heavy use. | Construction, heavy machinery, testing equipment. | 0-20,000 |

| Temperature Stability | Maintains accuracy over a wide temperature range. | Food processing, chemical manufacturing. | 0-10,000 |

Benefits of Using Pancake Load Cells in Weighing Applications

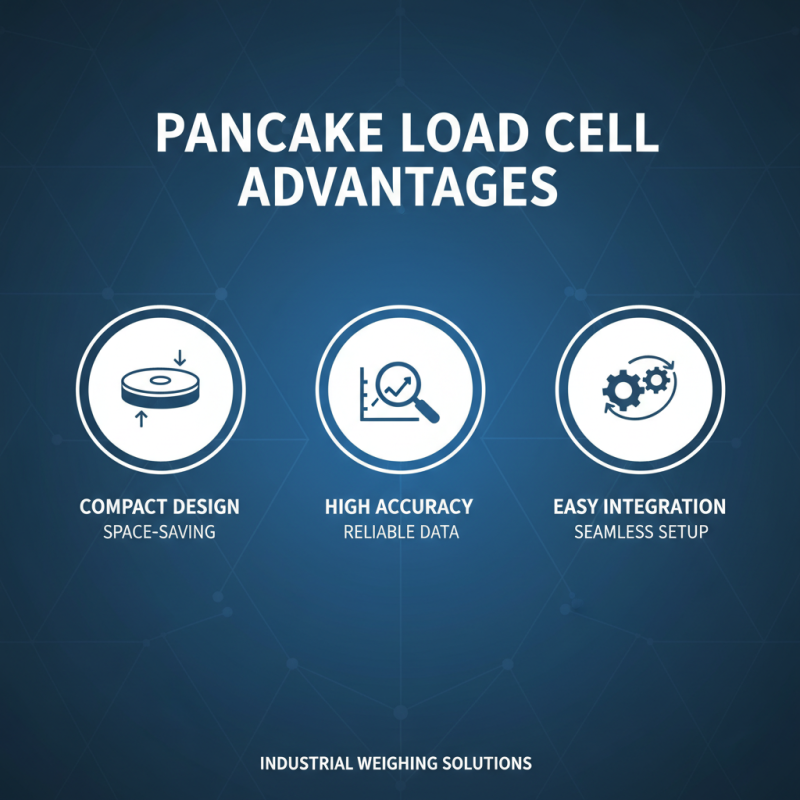

Pancake load cells bring several advantages to weighing applications. Their compact design allows for precise measurements in tight spaces. This is especially useful in industrial settings where every inch counts. Operators can easily integrate them into existing systems. They deliver high accuracy, ensuring reliable data collection.

Another benefit is their ability to handle large loads. Despite their slim profile, they can measure substantial weights without sacrificing performance. This can be crucial for heavy machinery or bulk materials. Users often appreciate this feature, as it reduces the need for multiple sensors.

However, challenges can arise. Installation may require adjustments to existing setups. It’s essential to calibrate the cells properly for optimal accuracy. Without careful setup, the measurements could be off. Regular maintenance is also necessary to ensure longevity. Despite these challenges, the advantages of pancake load cells are evident in many applications.

Best Practices for Installing Pancake Load Cells for Accurate Results

When installing pancake load cells, precision is key. The setup stage significantly impacts measuring accuracy. First, ensure the load cell is level. An unlevel installation can lead to incorrect readings. Use a spirit level to check before finalizing the position.

Proper alignment with the force application is crucial. Avoid side loads that might skew results. The load cell should only bear direct loads. If misaligned, it may produce false data. Always double-check the alignment during installation.

Consider environmental factors too. Temperature fluctuations can affect accuracy. Ensure the installation area maintains a steady temperature. Regular calibration is also essential. Failing to calibrate periodically can lead to compounding errors. Trust your process, but remain ready to adapt and refine your approach.

Calibration Techniques for Ensuring Precision in Pancake Load Cells

Calibration is vital for ensuring precision in pancake load cells. These devices measure weight by converting force into an electrical signal. However, factors like temperature and material can affect accuracy. Regular calibration helps mitigate these issues and maintain reliable readings.

A common method for calibration involves applying known weights to the load cell. Placing these weights accurately is crucial. Even slight deviations can lead to incorrect measurements. After recording the outputs, technicians can adjust the load cell settings. Each adjustment fine-tunes its responsiveness to weight changes.

In practice, some users overlook environmental conditions. Humidity and vibration can impact results. It’s essential to establish a stable environment for testing. Regular checks, perhaps bi-weekly or monthly, can prevent drift in measurements. Employing these techniques strengthens the precision of pancake load cells, ensuring they perform optimally in various applications.

Common Issues and Troubleshooting Tips for Pancake Load Cells

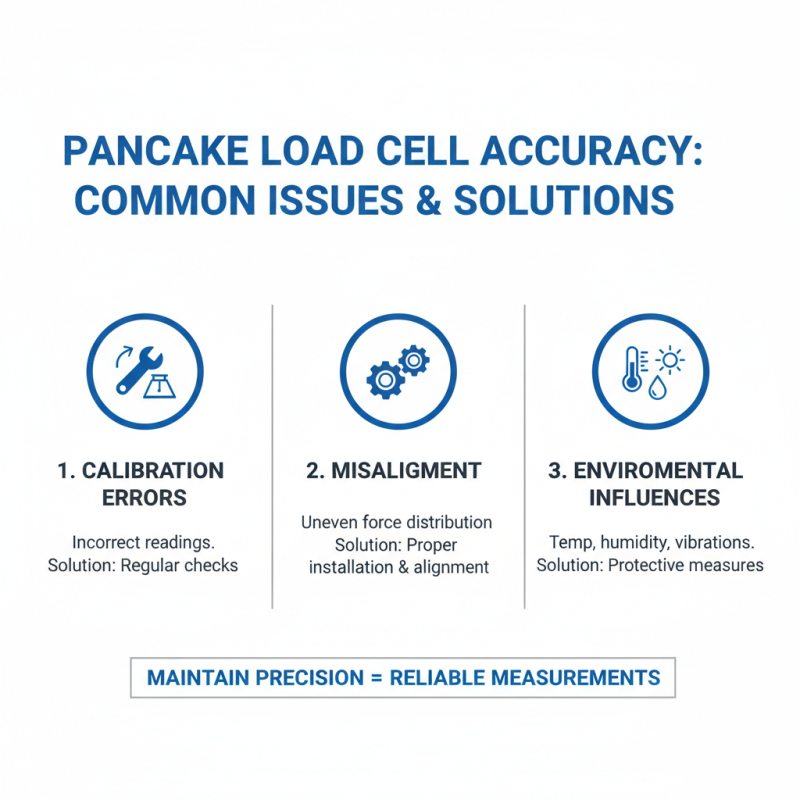

Pancake load cells are widely used for precise weighing applications. However, they can experience issues that affect accuracy. Common problems include calibration errors, misalignment, and environmental influences. If a pancake load cell is not calibrated correctly, it may provide inaccurate readings. Regular calibration checks are vital to maintaining accuracy.

Misalignment is another significant issue. When a load cell is not aligned properly, it can produce erroneous measurements. Visual checks and proper installation are essential. Take care to install the cell on a stable surface. External factors like temperature and humidity can also impact performance. Ensure the load cell is in a controlled environment.

Sometimes, troubleshooting a pancake load cell can be frustrating. A simple inspection may reveal loose connections or damaged cables. These issues can lead to unreliable data. Don’t overlook the need for regular maintenance. Keeping an eye on these details can help sustain optimal performance. Addressing these common challenges will improve the reliability of your weighing system.

Related Posts

-

Unlocking Efficiency: Key Advantages of Utilizing Compression Load Cells in Industrial Applications

-

Top 10 Pancake Load Cell Manufacturers from China at the 137th Canton Fair

-

Top Pancake Load Cell Applications in Industry and Science?

-

Transforming Weighing Solutions at the 138th Canton Fair in 2025 with Pancake Load Cell Technology

-

Unlocking Precision: Essential Tips for Choosing the Right Ring Load Cell for Your Needs

-

How to Choose the Best Low Profile Load Cell for Your Application