sales@loadcellsensor.com

sales@loadcellsensor.com

Top Load Cell Types and Their Applications in Industrial Weighing Systems

In the rapidly evolving landscape of industrial weighing systems, load cells play a pivotal role in ensuring accuracy and reliability across various applications. Experts in the field, such as Dr. John Harman, a leading authority on weighing technologies, have emphasized the significance of load cells by stating, "The precision of a load cell directly influences the efficiency and integrity of industrial operations." This underscores the essential nature of load cells in delivering precise measurements that businesses rely on for their operational success.

Load cells come in various types, each tailored to meet specific industrial needs. From tension and compression load cells to bending beam and shear beam designs, understanding these different variations is crucial for selecting the appropriate technology for any given application. Industries ranging from manufacturing to logistics leverage these devices to enhance performance and maintain high standards in quality control.

As we delve deeper into the topic of load cell types and their applications, it becomes clear that these devices are not just components of weighing systems; they are foundational elements that support the backbone of numerous industrial operations. Their ability to provide consistent and accurate weight readings drives productivity and fosters trust in measurement processes across the industrial spectrum.

Types of Load Cells: Strain Gauge, Capacitive, and Pneumatic Overview

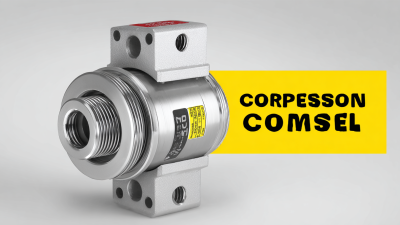

Load cells are essential components in industrial weighing systems, serving to convert force into an electrical signal that can be measured. Among the various types of load cells, strain gauge, capacitive, and pneumatic designs are the most prevalent, each offering distinct advantages suited for specific applications.

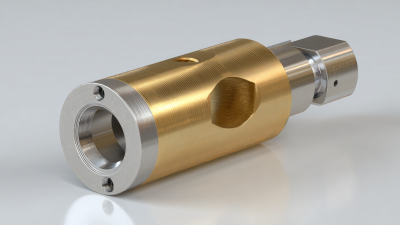

Strain gauge load cells are the most widely used type in industrial settings. They operate on the principle of measuring the deformation of a material under applied force. The strain gauge is bonded to a metal element that flexes when weight is applied, resulting in a change in resistance. This change is converted into a readable signal, making strain gauge load cells ideal for most general weighing applications due to their accuracy and reliability.

Capacitive load cells, on the other hand, function by detecting changes in capacitance as a load is applied. These load cells are highly sensitive and can provide precise measurements even for very small weights. They excel in applications where environmental conditions are stable, such as laboratory settings or specialized industrial processes. Pneumatic load cells utilize air pressure to measure loads, offering the advantage of resiliency against overload and high-temperature conditions. They are often seen in heavy-duty applications, such as weighing containers or buses in manufacturing settings, where durability and accurate measurement are crucial.

Industrial Applications: How Load Cells Enhance Weighing Accuracy

Load cells play a crucial role in enhancing the accuracy of weighing systems in various industrial applications. By converting a force or weight into an electrical signal, these devices ensure precision in measurement, which is essential for industries such as pharmaceuticals, food and beverage, and manufacturing. In scenarios where even the slightest deviation in weight can lead to significant operational issues, load cells provide the necessary reliability. Their ability to function under different conditions, such as varying temperatures and environments, makes them indispensable in maintaining quality control and inventory management processes.

Moreover, the integration of load cells in automated systems contributes to improved efficiency and data collection. In automated packing lines, for instance, load cells help to ensure that each product is weighed accurately before packaging, reducing waste and potential financial loss. In addition, many modern load cells are equipped with digital outputs, allowing for real-time data access and monitoring. This capability enables industries to make informed decisions quickly, further enhancing their operational efficiency and accuracy. Overall, the implementation of load cells not only secures precise measurements but also supports the broader goals of productivity and sustainability in industrial weighing systems.

Comparative Analysis: Load Cell Performance in Different Environments

Load cells are integral components in industrial weighing systems, yet their performance can vary significantly depending on environmental conditions. For instance, temperature fluctuations can impact the accuracy of load cell readings. According to a report from the International Society of Automation, temperature changes of 1°C can lead to a deviation of 0.01% in measurement accuracy for certain types of load cells. This highlights the necessity for manufacturers to select load cells that are specifically designed to withstand environmental stresses, such as those found in extreme temperatures or humidity levels.

Moreover, factors like vibration and electromagnetic interference also play a critical role in load cell performance. A study published in the Journal of Measurement Science indicated that load cells operating in high-vibration environments, such as manufacturing plants, may experience significant signal noise, which could compromise measurement precision by up to 0.05%. As such, understanding the specific challenges of the operational environment is vital. Load cells such as strain gauge and piezoelectric models offer different advantages; for example, strain gauge load cells are known for their stability in both dynamic and static situations, making them ideal for environments with fluctuating loads. Thus, selecting the appropriate load cell type based on environmental conditions is essential for achieving optimal performance in industrial weighing applications.

Load Cell Performance in Different Environments

Load Cell Specifications: Understanding Capacity, Sensitivity, and Linearity

When evaluating load cells for industrial weighing systems, understanding specifications such as capacity, sensitivity, and linearity is crucial. Load cell capacity refers to the maximum weight that the device can accurately measure. Selecting a load cell with an appropriate capacity is essential to ensure optimal performance and prevent damage. Often, a safety margin is included to account for unexpected overloads, which is vital in environments where weights can fluctuate significantly.

Sensitivity, on the other hand, reflects the load cell's ability to detect small changes in weight. It is defined as the ratio of the output signal to the applied load. High sensitivity is particularly important in applications requiring precise measurements, such as in laboratory settings or quality control processes. Ensuring a load cell has adequate sensitivity can enhance the accuracy of measurements and provide reliable data for decision-making.

Linearity describes how accurately the load cell's output correlates with the input load across its range. Ideally, the output should be a straight line when graphed against the applied load. Non-linearity can lead to errors in measurement, especially at the extremes of capacity. Understanding these specifications helps engineers choose the appropriate load cell for their specific application, ensuring that the measuring systems are both accurate and reliable in demanding industrial environments.

Future Trends: Innovations in Load Cell Technology for Industrial Use

The future of load cell technology in industrial weighing systems is poised for significant innovation, driven by advancements in materials science, miniaturization, and data analytics. As industries continue to embrace automation, the development of smart load cells that can provide real-time data and enhanced accuracy will become increasingly vital. These next-generation load cells are anticipated to integrate with IoT systems, allowing for seamless data collection and remote monitoring. This capability not only improves operational efficiency but also enables predictive maintenance, reducing downtime and operational costs.

Tips: When considering upgrades to your weighing systems, focus on load cells that offer modular designs for easy maintenance and adaptability to different applications. Prioritize options that facilitate connectivity and data integration for streamlined operations.

Furthermore, innovations in load cell technology will likely emphasize sustainability. Future load cells may utilize eco-friendly materials and energy-efficient designs to reduce their environmental impact. As industries face increasing pressure to adopt green practices, the shift towards sustainable components will be essential for compliance and corporate responsibility.

Tips: Assess the lifecycle impact of load cells when making purchasing decisions, as more environmentally friendly options can enhance both your brand's image and operational sustainability. Additionally, keep an eye on emerging technologies that could redefine load cell functionalities, like advanced machine learning algorithms for better data interpretation.

Related Posts

-

Understanding the Benefits of Through Hole Load Cell for Accurate Measurements

-

Top Strategies for Selecting the Best 5kg Load Cell for Your Business Needs

-

The Ultimate Guide to Choosing the Best Load Cell for Your Needs

-

5 Essential Tips for Choosing the Right Thin Load Cell

-

Discovering the Best Compression Load Cells: A Global Buyer’s Guide for Performance and Reliability

-

Unlocking Precision: Essential Tips for Choosing the Right Ring Load Cell for Your Needs