sales@loadcellsensor.com

sales@loadcellsensor.com

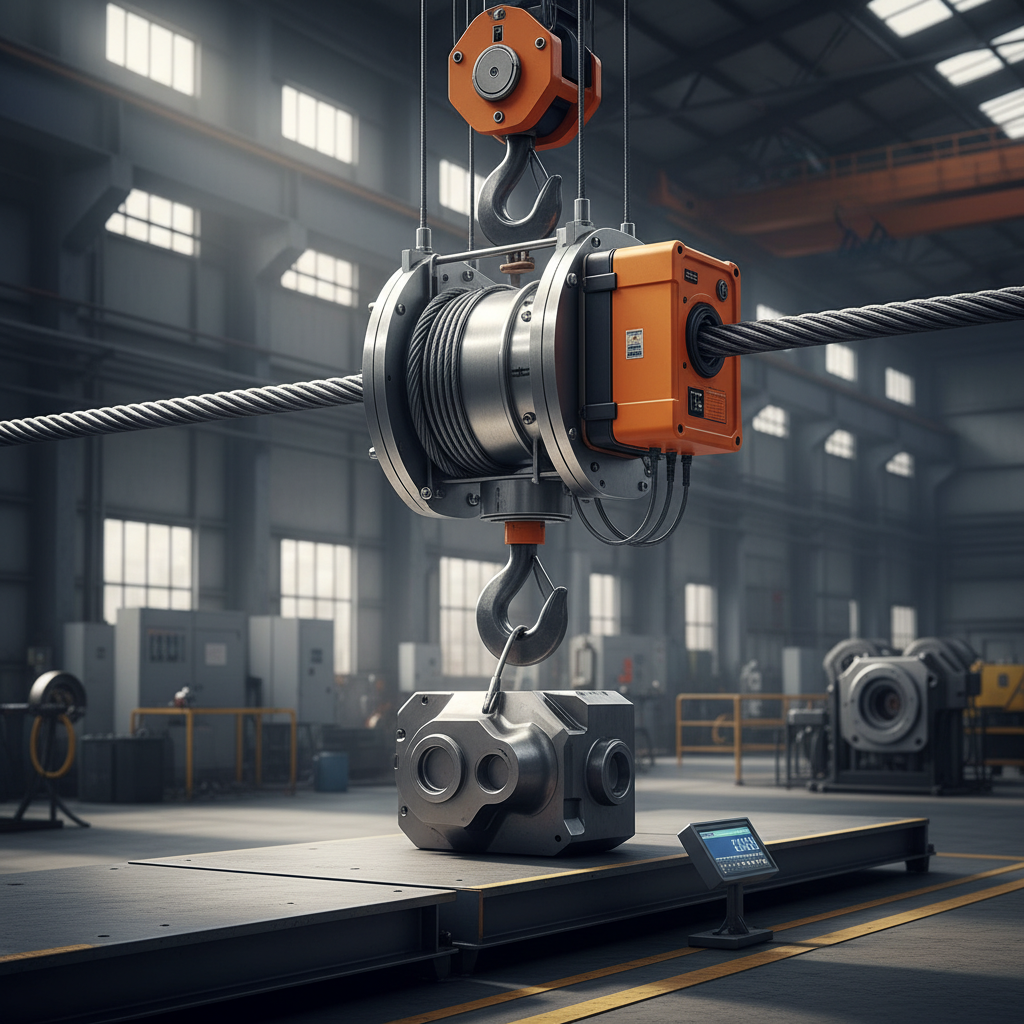

What Is a Wire Rope Load Cell and How Does It Work in Weighing Applications?

In the realm of precision weighing solutions, the

Wire Rope Load Cell stands out as a pivotal component,

facilitating accurate measurements in various industrial applications. Understanding how these

devices operate is essential for engineers and operators alike, as they often play a critical

role in ensuring the safety and efficiency of lifting and weighing operations. By

leveraging the unique properties of wire rope, these load cells provide reliable performance

under significant loads, making them indispensable in environments ranging from construction

sites to manufacturing facilities.

Typically constructed with robust materials, Wire Rope Load Cells are designed to withstand harsh

conditions while delivering consistent results. The mechanism behind their functionality is rooted in

the principles of tension and deformation, which allows them to

convert mechanical stress into an electrical signal that represents the weight being measured.

As industries continue to evolve and demand more sophisticated weighing solutions,

understanding the advantages and principles of Wire Rope Load Cells becomes crucial for

optimizing operations and ensuring compliance with safety standards.

Understanding Wire Rope Load Cells: Key Components and Features

Wire rope load cells are crucial components in various weighing applications, providing accurate measurements by utilizing a series of wires and mechanical principles. These devices are built to withstand significant loads, making them suitable for industrial environments where precision is paramount. Typically, a wire rope load cell consists of a load-bearing element made of high-strength materials, a mechanism to convert force into an electrical signal, and a protective casing to safeguard against environmental factors.

Wire rope load cells are crucial components in various weighing applications, providing accurate measurements by utilizing a series of wires and mechanical principles. These devices are built to withstand significant loads, making them suitable for industrial environments where precision is paramount. Typically, a wire rope load cell consists of a load-bearing element made of high-strength materials, a mechanism to convert force into an electrical signal, and a protective casing to safeguard against environmental factors.

In addition to their robust design, wire rope load cells offer several advanced features that enhance their performance. For instance, they often come equipped with capabilities to log pressure and stress, similar to how load cells measure normal stresses in subglacial systems. This versatility allows them to be integrated into various applications, from truck scales, which require precise weight recording for quality control in industries like food, to complex automation systems that utilize load-cell amplifiers for real-time data processing.

Tips: When considering a wire rope load cell for your project, ensure that you select one with appropriate load capacities and features tailored to your specific needs. Regular maintenance and calibration can also help maintain accuracy and extend the life of the device, especially in high-demand applications.

The Working Principle of Wire Rope Load Cells in Weighing Applications

Wire rope load cells are essential devices used in various weighing applications, exhibiting high accuracy and durability. The working principle of these load cells is based on the tension created in a wire rope when a load is applied. As weight is added, the tension in the wire rope increases, causing a corresponding change in the electrical signals produced by the load cell. This change is measured, processed, and converted into a readable weight value. Typically constructed from high-strength materials, they are designed to withstand harsh environmental conditions, ensuring reliable performance in industrial settings.

Tips: When utilizing wire rope load cells, it is crucial to ensure that the load is evenly distributed across the wire rope to maintain accuracy. Regular calibration and maintenance of the load cell can also enhance its lifespan and precision, safeguarding your investment in weighing technology.

Moreover, understanding the load cell's specifications—such as its maximum load capacity and sensitivity—is important for optimal performance. Correct setup and adherence to the manufacturer's guidelines can minimize operational issues, providing consistent and precise weight measurements even under dynamic conditions.

Advantages of Using Wire Rope Load Cells for Industrial Weighing

Wire rope load cells are increasingly favored in industrial weighing applications due to their unique advantages. One of their primary benefits is their ability to handle heavy loads while maintaining high precision. The design of wire rope load cells allows them to efficiently distribute weight across multiple points, reducing the risk of overload and ensuring accurate measurements even in challenging environments. This capability makes them particularly valuable in sectors like construction, shipping, and manufacturing, where large-scale weighting is a routine necessity.

Another significant advantage of wire rope load cells is their durability and resilience. Constructed with robust materials, they can withstand harsh operational conditions, including exposure to moisture, dust, and extreme temperatures. This durability not only extends the lifespan of the load cell but also minimizes maintenance costs over time. Moreover, their relatively lightweight design facilitates easier installation and transportation, making them ideal for mobile applications or situations where space is constrained. Overall, wire rope load cells provide a reliable solution for industries seeking precise and durable weighing mechanisms.

What Is a Wire Rope Load Cell and How Does It Work in Weighing Applications? - Advantages of Using Wire Rope Load Cells for Industrial Weighing

| Dimension | Specification | Advantages | Applications |

|---|---|---|---|

| Rated Load | Up to 100 tons | High load capacity | Heavy machinery weighing |

| Accuracy | ±0.1% of full scale | High precision measurements | Construction site applications |

| Temperature Range | -20°C to +60°C | Wide operating temperature | Outdoor weighing systems |

| Material | Stainless steel | Corrosion resistance | Marine applications |

| Installation Type | Portable or fixed | Flexible installation | Warehouse operations |

Applications of Wire Rope Load Cells Across Various Industries

Wire rope load cells have emerged as essential components in various industries where precise weighing is crucial. In construction and heavy machinery, these load cells are frequently employed in cranes and hoists, helping to ensure the safety and efficiency of operations. According to a report from MarketsandMarkets, the global material handling equipment market, which includes cranes utilizing wire rope load cells, is projected to reach $48.9 billion by 2025, underscoring the growing reliance on accurate load measurement technologies in demanding environments.

In the manufacturing sector, wire rope load cells are integral for quality control and process optimization. These devices facilitate real-time monitoring of loads during production, thus minimizing the risk of overloads that could lead to equipment failure or accidents. A study by Grand View Research indicates that the global load cell market is expected to grow at a CAGR of 5.2% from 2021 to 2028, reflecting the ongoing investment in advanced weighing technologies across various industries. Additionally, the rise of smart factories further emphasizes the role of wire rope load cells in automation and data acquisition, enhancing operational efficiency and product safety.

Maintenance and Calibration Tips for Optimal Performance of Load Cells

Maintaining the optimal performance of wire rope load cells is crucial for ensuring accurate weighing in various industrial applications. Regular maintenance not only extends the lifespan of the load cells but also enhances their precision. According to a report by the International Society of Automation, improper calibration and neglecting maintenance can lead to measurement errors of up to 5%, significantly impacting operational efficiency. To avoid these pitfalls, a systematic approach to maintenance is essential. This includes routine checks for signs of wear or damage, cleaning the load cells to prevent dust and debris accumulation, and ensuring that all connections are secure and intact.

Calibration is another vital component in the upkeep of wire rope load cells. Industry standards recommend calibrating load cells at least once a year, or more frequently in high-usage environments. A study published in the Journal of Weighing Science indicates that periodic calibration can improve measurement accuracy by as much as 10%, ensuring compliance with industry regulations. Operators should use certified calibration weights and follow the manufacturer's guidelines closely. Implementing these maintenance and calibration strategies not only improves the reliability of wire rope load cells but also fosters safety and efficiency in weighing operations across various sectors.

Related Posts

-

Exploring the Future of Load Cells: Innovations Beyond the Best Bending Beam by 2025

-

Identifying Key Issues in Bending Beam Load Cell Usage and Their Impact on Accuracy

-

Unlocking Precision: Essential Tips for Choosing the Right Ring Load Cell for Your Needs

-

Understanding Inline Load Cells: Revolutionizing Weight Measurement in Modern Industries

-

Understanding the Science Behind Torque Load Cells: Applications and Innovations

-

Unlocking Industry Potential with Strain Gauge Load Cells at the 2025 China Import and Export Fair